16

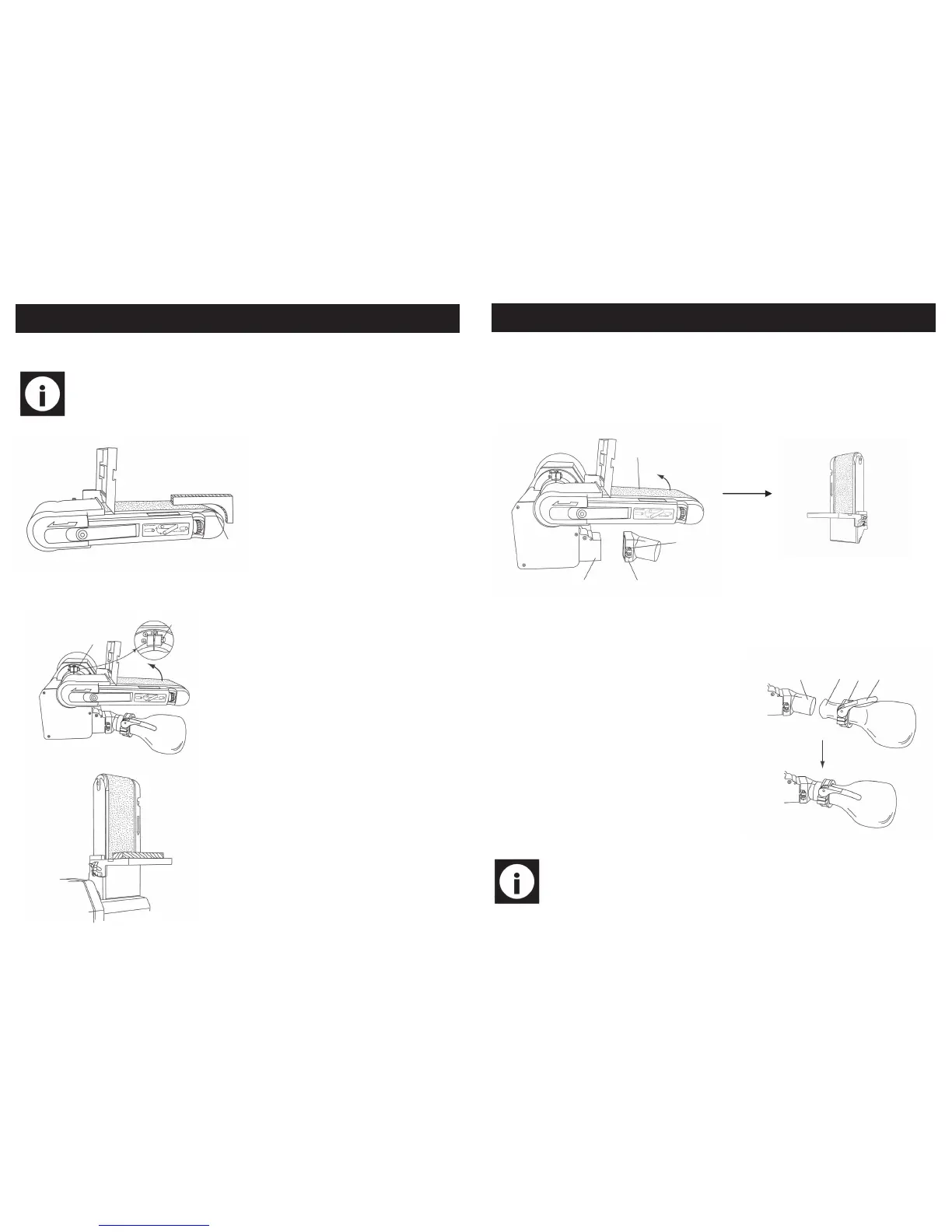

Sanding inside curves.

Note: To avoid injury, do not apply the end of the work piece to the idler

drum (1). This could cause the work piece to fly up or cause kickback.

1

With care, freehand sanding of inside

curves can be accomplished on the

idler drum (1). Never attempt to sand

the ends of a work piece on the idler

drum (1).

Belt vertical sanding.

1

1

The belt / disc sander can sand vertically as well

as horizontally. Depending on operator needs

and the work piece, the worktable can be used

with either the horizontal or vertical position.

1.Locate the 5 mm hex key.

2.Loosen the inner hex screw (1) by turning it anti

-clockwise.

3.Manually move the sanding bed into the verti-

cal or horizontal position, as required.

4.Re-tighten the inner hex screw (1) by turning it

clockwise.

OPERATING INSTRUCTIONS….cont

13

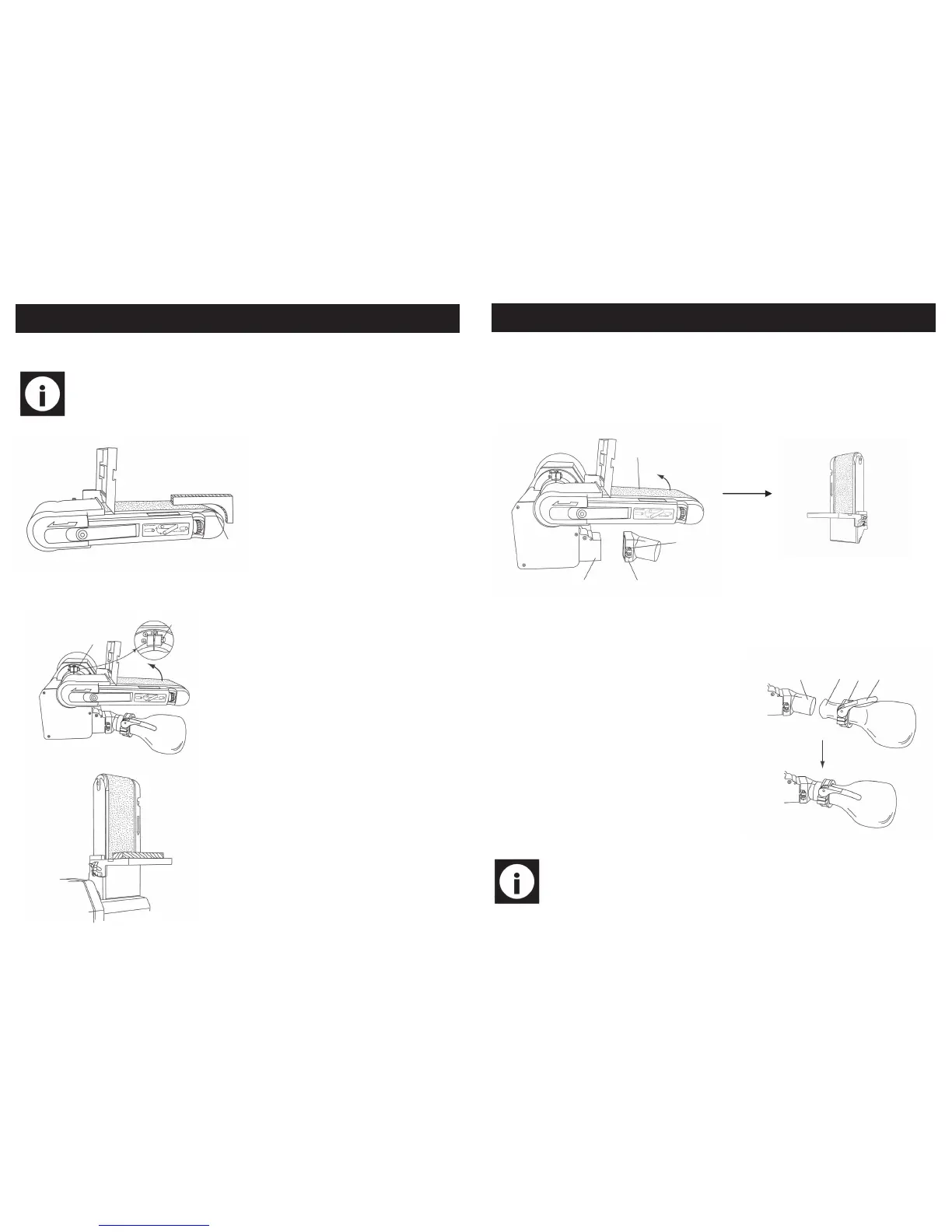

Attaching the extraction port.

1

2

3

4

1.Ensure that the belt bed (1) is in the vertical position (as shown on page12).

2.Loosen the hex screw (2) using a 5mm hex screw, attach the dust extraction port (3)

onto the dust port (4), and re-tighten the hex screw (2).

Note: It is extremely important that the dust bag is connected to the ma-

chine before any sanding operations are carried out, we also recommend

using a mask or respirator even when the dust bag is connected,

3

4

5

6

3.Insert the opening of the dust bag (4) into

bag clamp (5).

4.Attach the dust bag (4) onto the dust port

(3).

5.Tighten the bag clamp handle (7) clockwise

one or two full turns before locking, do not

over tighten.

Attaching the dust bag.

ASSEMBLEY INSTRUCTIONS….cont

Loading...

Loading...