Instruction for work

20

5. Maintenance and periodical overhauls

5.1 Special sefety instructions

– Repair works, maintenance, periodical

overhauls, cleaning and elimination of

functional disturbances must be

performed with the switched off drive

and stand still engine! Remove the

ignition key!

– Do not use excessive quantities of oil

and grease. Be friendly to nature.

– When injured with splashed oil find

medical help immidiately.

– Consider other safety instructions to

prevent damages and accidents.

5.2 General

–

To insure faultless working of the

machine and to reduce the wear out

always consider the maintenance

instructions and periodical overhauls.

This includes cleaning, greasing and

lubricating of built in parts and

components.

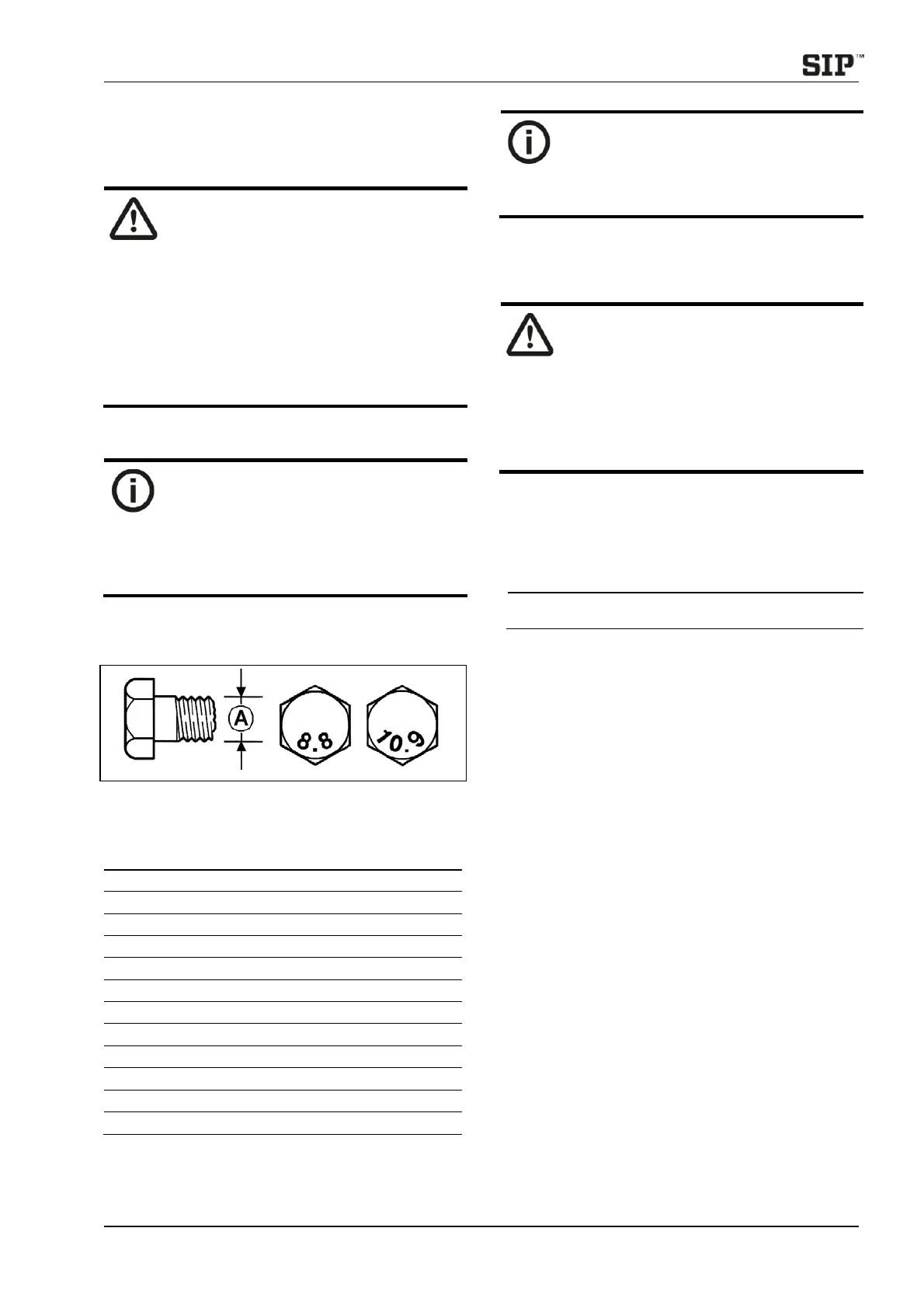

Screws and nuts tightening moment M

A

(if not stated otherwise)

A = size of coil

A

Ø

8.8 10.9 12.9

M

A

(Nm)

M 5 5,9 8,7 10

M 6 10 15 18

M 8 25 36 43

M 10

49 72 84

M 12 85 125 145

M 14 135 200 235

M 16 210 310 365

M 20 425 610 710

M 24 730 1050 1220

M 27 1100 1550 1800

M 30 1450 2100 2450

After the first start and few hours of

working check the tightness of nuts

and screws, tighten them if needed.

Check up regulary (approx. every 50

hours)!

5.3 Tyres

– To mount tyres sufficient knowledge

and regulation tools are required.

– Repair works on tyres are allowed to be

performed by professionals with proper

tools only.

– Place the machine on flat and solid

ground. Secure it with wedges against

unintentional rolling off.

– Check the tyre pressure regularly.

Check the tyre pressure regularly and fill it up if

needed, Compare the measured values with the values

given in the table.

Type Tyre

Pressure

(bar)

SPIDER 400/4 ALP 15 x 6,00 - 6 2

5.4 Lubrication

In the figure all the lubrication spots are marked. Long

life of the swather is achieved if the time intervals

shown here are met.

5.5 Gear maintenance

Middle gaer must be filled with half liquid grease EP –

00.

Loading...

Loading...