0

NOTE: Track tension and align-

ment

are inter-related.

Do

not ad-

just one

without

the other.

Alignment

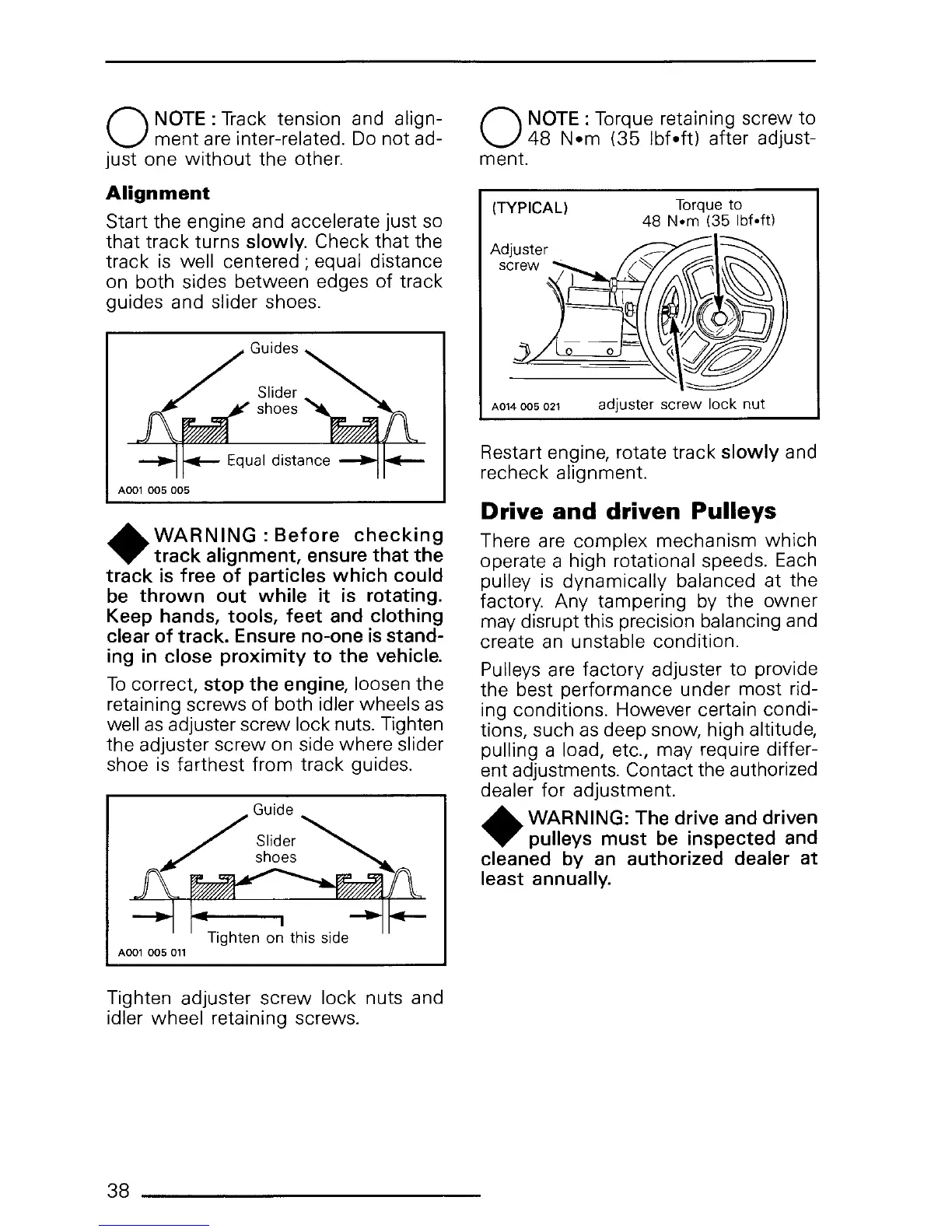

Start the engine and accelerate just so

that track turns

slowly. Check that the

track

is

well centered ; equal distance

on both sides between edges of track

guides and slider shoes.

A001

005 005

•

WARNING:

Before

checking

track alignment, ensure that the

track

is

free of particles which could

be

thrown out while it

is

rotating.

Keep hands, tools, feet

and

clothing

clear of track.

Ensure

no-one

is

stand-

ing

in

close proximity to the vehicle.

To

correct, stop the engine, loosen the

retaining screws

of

both idler wheels

as

well

as

adjuster screw lock nuts. Tighten

the adjuster screw on side where slider

shoe

is

farthest from track guides.

/:~~:r~

/ shoes

~

d4~

A001

005

011

Tighten adjuster screw lock nuts and

idler wheel retaining screws.

38

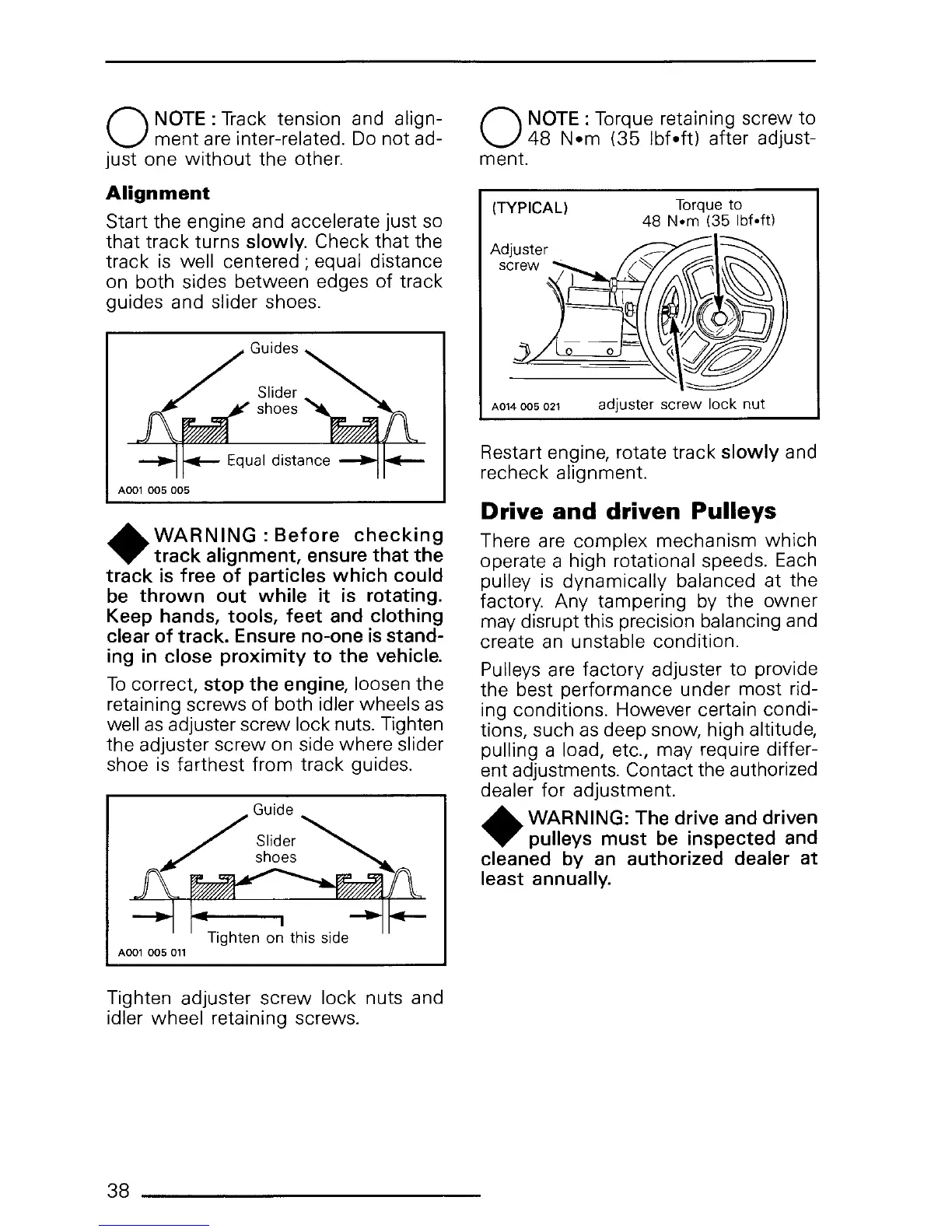

0

NOTE

:Torque retaining screw to

48

N•m

(35

lbf•ft)

after adjust-

ment.

(TYPICAL)

Adjuster

screw

A014

005

021

Torque

to

48

N•m

(35 lbf•ft)

adjuster screw lock nut

Restart engine, rotate track slowly and

recheck alignment.

Drive

and

driven Pulleys

There are complex mechanism which

operate a high rotational speeds.

Each

pulley

is

dynamically balanced at the

factory. Any tampering by the owner

may disrupt this precision balancing and

create

an

unstable condition.

Pulleys are factory adjuster to provide

the best performance under most rid-

ing conditions. However certain condi-

tions, such

as

deep snow, high altitude,

pulling a load, etc., may require differ-

ent adjustments. Contact the authorized

dealer for adjustment.

•

WARNING: The drive

and

driven

pulleys must

be

inspected

and

cleaned

by

an

authorized dealer at

least annually.

Loading...

Loading...