Edition: 2021-01-29

ETNSTCI/ETNSTCILF Installation Manual

Page 12 of 14

Revision

A

Signature

Date

8

Checked

B

C

76

Revision note

RevNo

5

D

E

F

Approved by - date

Sheet

Edition date

Checked by

8

Scale

6 7

Designed by Date

4

32

1

A

B

C

2 3

D

E

1

F

Doc. Instr. for Ice Tank ETNSTCILF

00

1 of 1

PC - 2011.11.04

HK

2011.10.27

SKIPPER Electronics AS

DI-ETNSTCILF

292

42

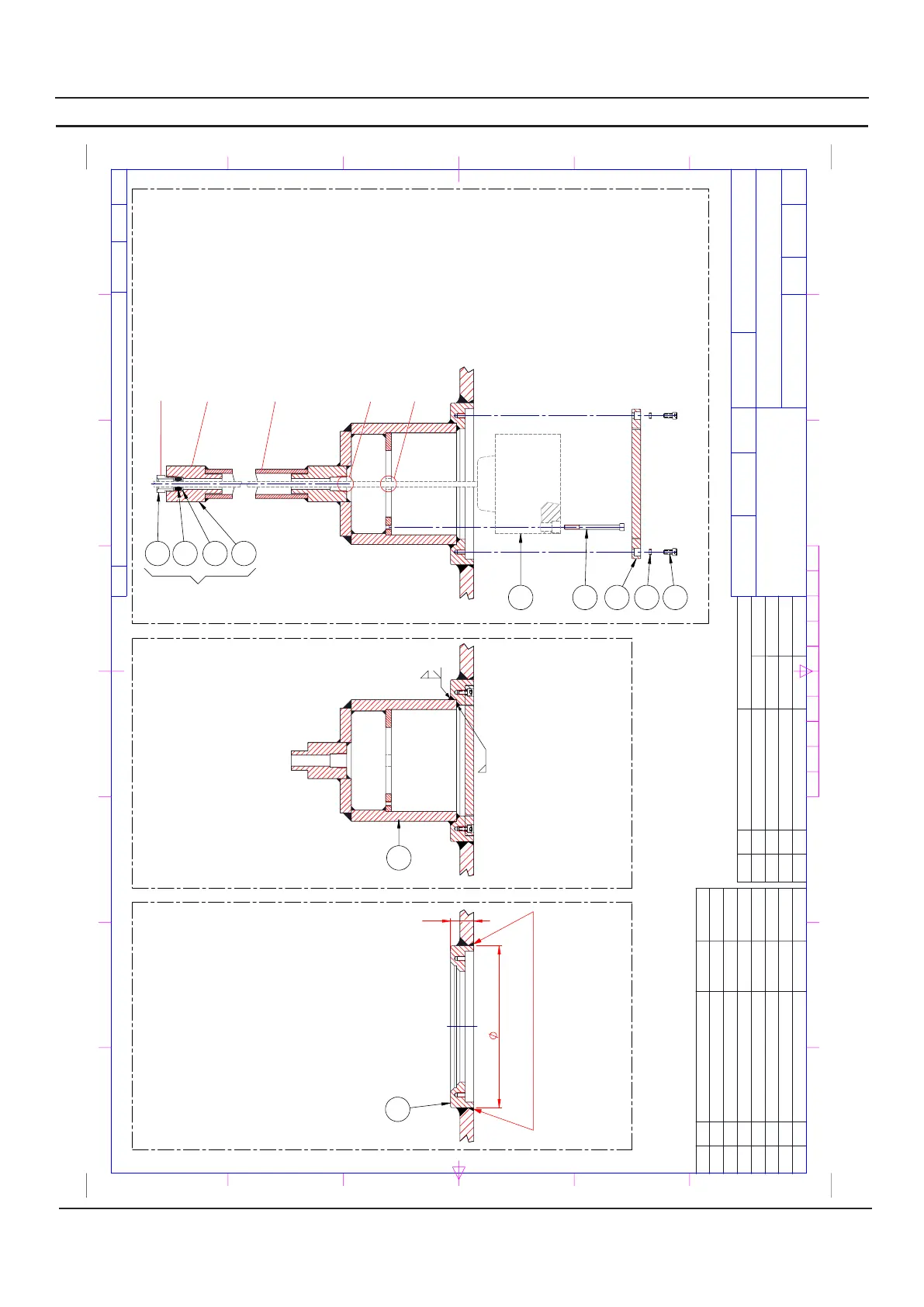

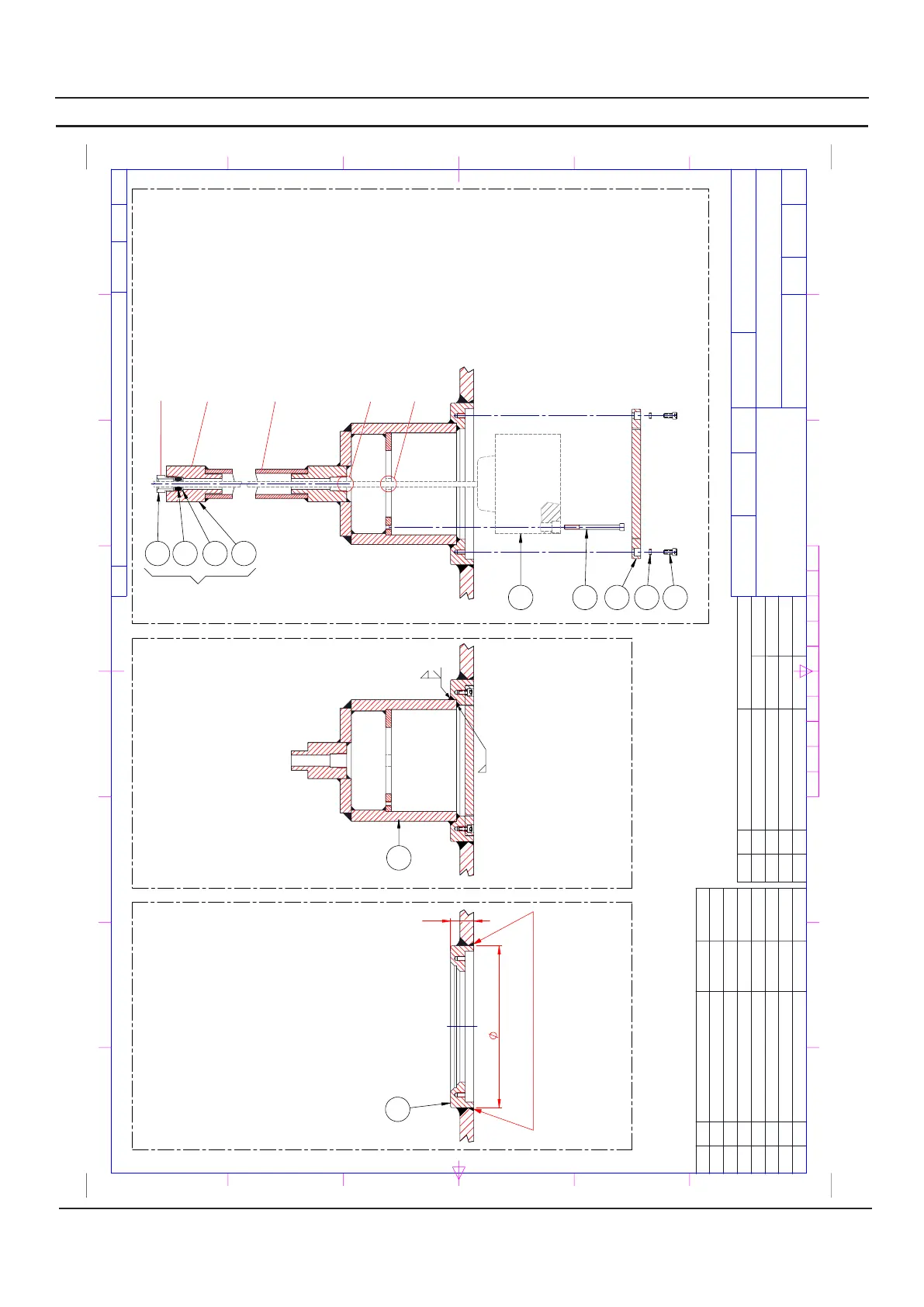

Welding Guidance for Transducer Tank:

See Drawing TB-3001

6

8

Observe proper Grinding of outer Hull Welding.

Material: AISI 316L / WNO 1.4404

01

02

09

04

03

08

13

NB! The 2 opposite Slots must not be

filled wiht Grease or similar.

(This is done to secure Water penetration)

DO NOT mount Cable Gland

inside the Ice Tank

Steel Pipe, minimum 35mm inside.

Wall thickness on galvanized Pipe:

8mm, on black Pipe: 10mm.

Quality of material as stated in

D.N.V. Rules chap.X Para 7A, type III.

The Pipe to be welded and cooled off

before pulling the Cable.

Cable stuffing Tube to be welded

to end of Cable Pipe at a position

well above Load Water Line.

After docking out it may be

necessary to open

Gable Gland to release

air from Tank

12

06

07

05

* To be ordered separatly

Transducer Tank Combo

Tank, Bottom Flange Ice 24/38kHz

ITEM

02

01

QTY.

1

1

DESCRIPTION

QTY.

TC-2002

TC-2026

Dwg.No.

ITEM

08

DESCRIPTION

Part. No.

07 1

Bronze Nut, PG-Nipple

TC-2013

Rubber Gasket Ø23,5/12,5x15mm

SB-6029

105

Cable Gland, Steel 6"

TC-2024

11203 1

Tank, Protection Plate Ice 24/38kHz

TC-2025

Tank Cartridges Ice Plate

TC-2007

804

Allen Screw M8x100 DIN912 A4

3

Allen Screw M8x16 DIN912 A4

809

Washer M12 DIN125 A2

206

*13 1

Transducer 24/38kHz

ETN024T / ETN038T

ZOA-01016

ZOA-01053

Parts under Module ZZL-01011

Part. No.

ZOA-01017

ZOA-01008

ZOA-01051

Dwg.No

ZOA-01009

8. 24/38 kHz Transducer in ice tank ETNSTCILF TC-2002

SKIPPER Electronics AS

Loading...

Loading...