1. The motor slide may require adjustment after machine has been in service. Loosen jam nuts using provided wrench.

Using feed handles, position motor/slide assembly in the full up position. Using supplied hex key, equally turn

adjustment screws clockwise to increase slide tension or counterclockwise to decrease slide tension. Do not over tighten

adjustment screws. Excessive slide tension can damage the machine. Properly adjusted, the motor/slide assembly

should have no side to side movement and remain positioned without drifting down.

2. Keep bottom of magnet clean, free of chips, burrs, nicks, oil and other contaminants. Inspect magnet face

to ensure surface is flat and square. A worn magnet surface dramatically reduces magnetic holding force.

3. Periodically lubricate motor slide ways with lithium base grease.

4. Visually inspect arbor, sleeve and support bracket for wear.

5. Arbor runout should not exceed .0035 inches per revolution. This is most accurately measured by placing a dial

indicator needle inside of arbor bore and rotating arbor while observing indicator.

6. Inspect coolant system, reservoir, o-rings, lip seals and coolant collar for wear.

7. Inspect motor brushes and replace as needed.

8. Replace any worn parts and regularly tighten fasteners that have become loose during usage.

9. Regularly test machine by placing machine on non-ferrous material. Engage magnet switch.

Motor should not start.

regular maintenance

10

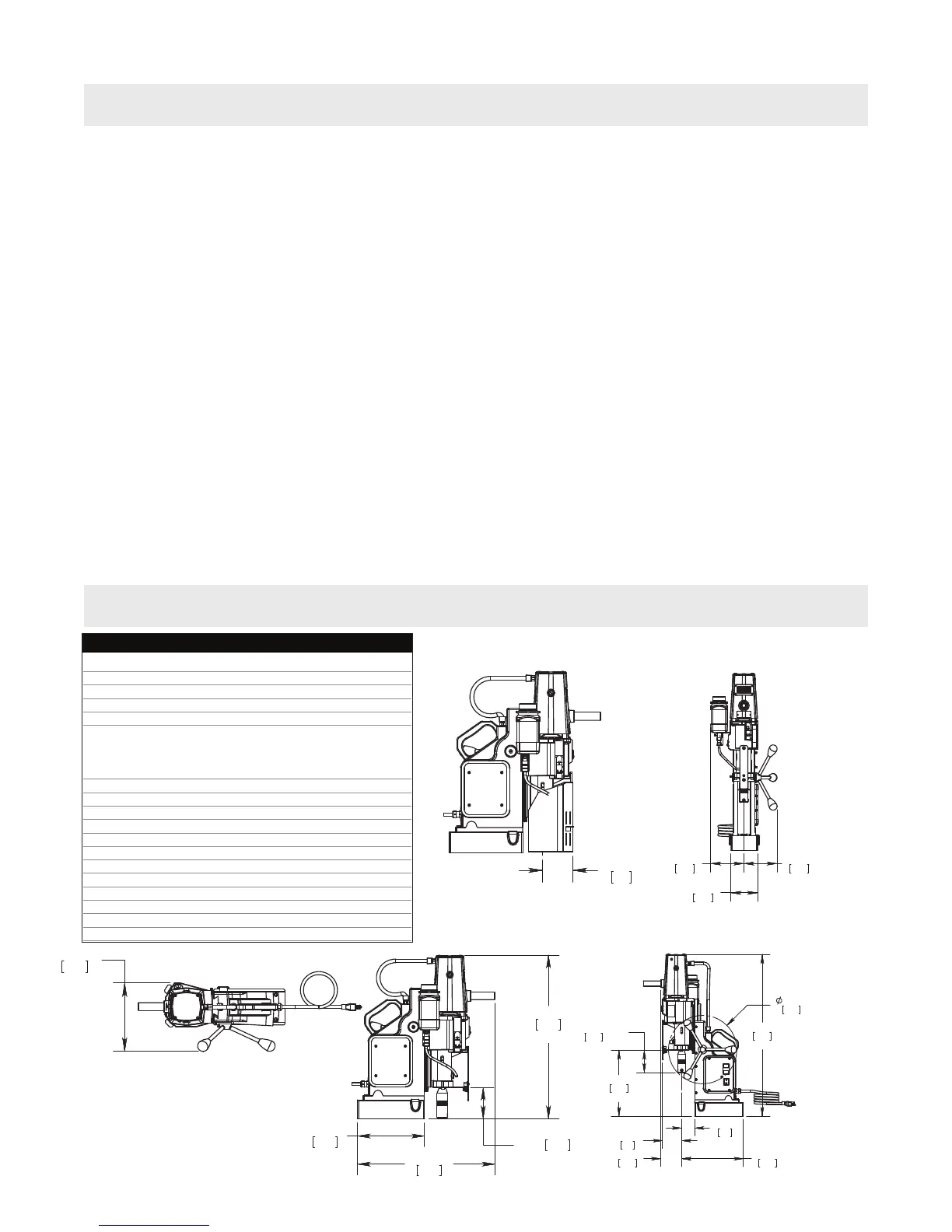

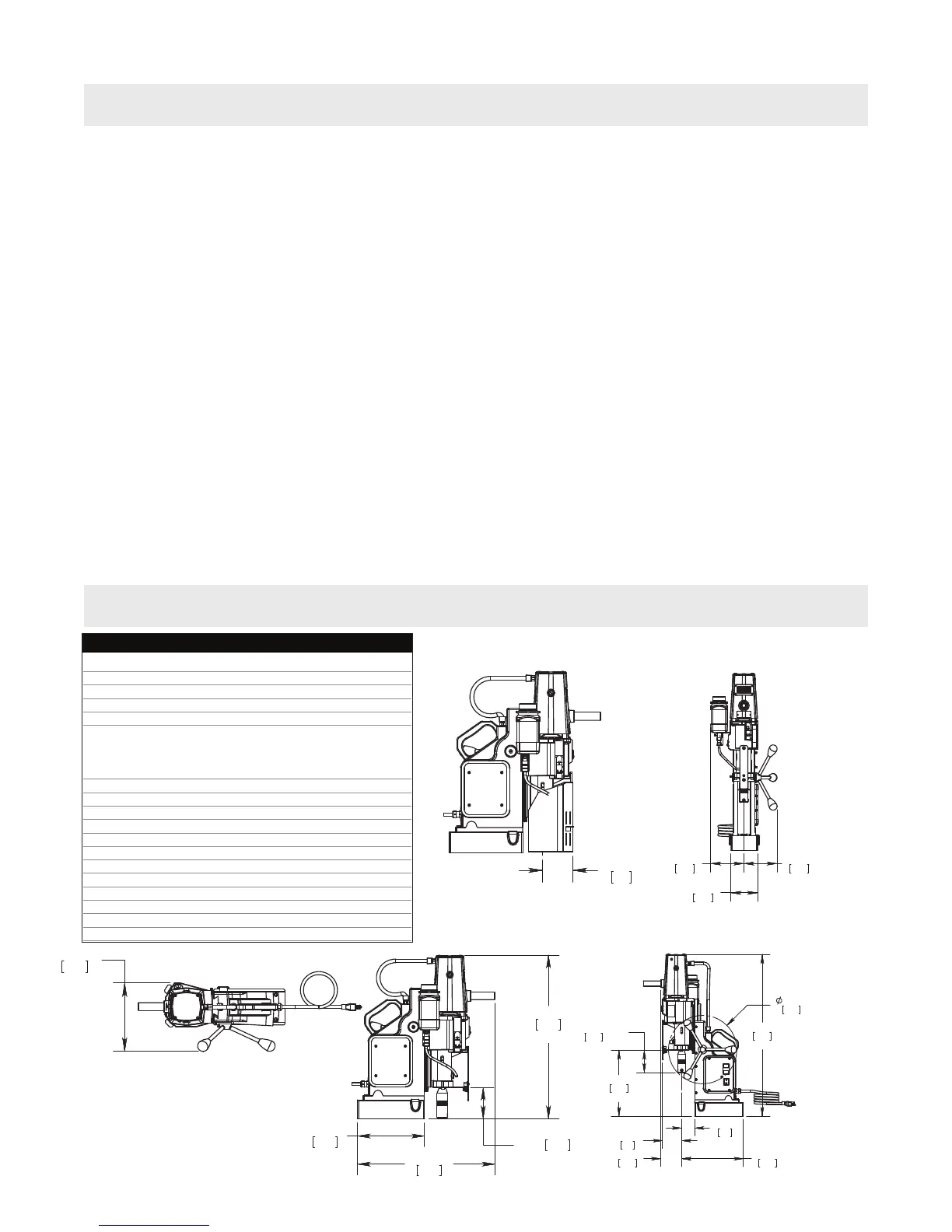

DIMENSIONS AND SPECIFICATIONS

Max Height 31-3/8" (797mm)

Min Height 23-1/8” (588mm)

Width 9-1/2" (242mm)

Length 16" (407mm)

Weight 73 lbs. (33Kg)

Motor 1.8 HP

1400W (single phase)

120V / 11.7A ~ 220V / 5.8A

150–240/ 290 – 450 RPM (no load)

100-150/200-310 RPM (load)

Spindle bore #3 morse taper

Arbor bore 3/4" (19.05mm)

Drill point breakaway 1934 lbs. on

1" plate (877Kg on 25mm plate)

Magnet base dimensions 4-3/4" x 9-1/2" (121mm x 242mm)

Magnet dead lift 4833 lbs. on 1" plate (2192Kg on 25mm plate)

Cutter diameter (maximum) 4" (102mm)

Slugger depth of cut (maximum) 3" (77mm)

Spindle CL to Guard Face 3-13/16" (97mm)

Spindle CL to Magnet Face 2-9/16" (65mm)

Spindle CL to Motor Face 3-15/16" (100mm)

Spindle CL to Motor Face 3-3/16" (81mm)

Total travel 8-7/16" (215mm)

3-7/8"

97

9"

230

493

19-3/8"

9-1/2"

240

112

(LESS ARBOR)

4-3/8"

23-1/8"

(DOWN)

586

13-1/4"

337

2-1/2"

64

12"

304

4"

103

3-3/4"

94

TYP.

110

(LESS ARBOR)

12-7/8"

326

4-3/8"

31-1/4"

(UP)

794

5-7/8"

150

5-7/8"

150

4-3/4"

120

dimensions and specifications

Loading...

Loading...