Remove all contents from packaging and inspect to ensure no damage was incurred during shipping. Your 4x4 package

should also include the following:

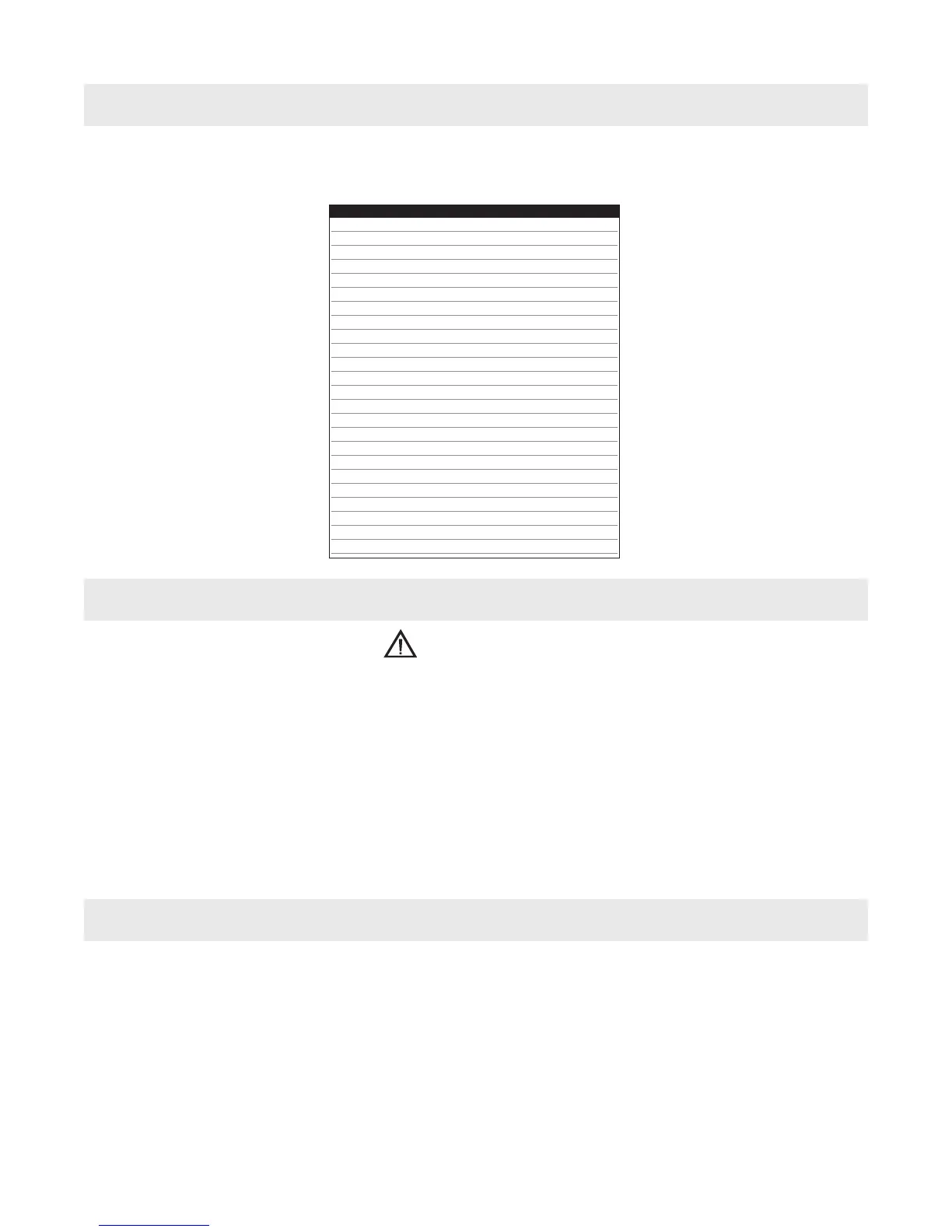

contents of package

description part # qty

DESCRIPTION PART # QTY,

OPERATOR'S MANUAL LIT103 1

PRODUCT DVD LIT032 1

WARRANTY CARD 0070342 1

3/16" PILOT, 1" DEPTH OF CUT 16001 1

3/16" PILOT, 2" DEPTH OF CUT 16002 1

1/4" PILOT, 1" DEPTH OF CUT 16003 1

1/4" PILOT, 2" DEPTH OF CUT 16004 1

1/4" PILOT, 3" DEPTH OF CUT 16005 1

2.5MM HEX WRENCH UH8000 1

4MM HEX WRENCH UH8002 1

5MM HEX WRENCH UH8003 1

5MM T-HANDLE HEX WRENCH UH6004 1

6MM HEX WRENCH UH8012 1

8MM COMBINATION WRENCH UH8006 1

SPOKE HANDLE 07319 3

SAFETY STRAP U11005 1

PIPE HANDLE 0010224 1

PIPE HANDLE ADAPTER 0010225 1

#3MT DRIFT UH8051 1

COOLANT BOTTLE ASSEMBLY 0151513 1

MAGNET WARNING NOTICE 0107D0C 1

SHUNT (ATTACHED TO HANSLE) UH5335 1

SHUNT INSTRUCTIONS 06958 1

getting started

what you should know before you drill

CAUTION!

always disconnect 4x4 from power source before making adjustments.

Refer to pages 7, 11 and 12. Assemble three spoke handles (item #22) to feed hub. NOTE: Feed hub assembly is

mounted on right side of machine frame–if necessary, it can be reversed for lefthand operation by simply removing the

fastener (item #24) and hub (item #21) from frame. Remove hub pinion shaft from right side of frame and insert it into

left side of frame. Replace hub and fastener into frame and tighten securely. Thread pipe handle into motor assembly

(item #5).

Install coolant bottle assembly (item #28) by sliding the bracket (included with assembly) onto 2 retaining screws (item

#27) located on the right side of the drill. Insert the hose connector into the fitting at the lower front of the gearcase.

1. Type of material to be drilled, Brinnell or Rockwell hardness, material thickness and position should all be

determined to ensure proper selection of Slugger® cutting tools, RPM, coolant and drilling time.

2. Remove any excessive mill scale or rust from surface to be drilled.

3. Material that has been flame cut may have become heat-treated and therefore difficult to drill. Avoid drilling near

such areas whenever possible.

4. Drilling with the 4x4 in horizontal positions requires a special lubrication for Slugger® cutters.

Consult Jancy Engineering for details.

5. The 4x4 is not designed for use on thin materials that will not hold magnet securely.

7

Loading...

Loading...