Doc. no. AMX-OMU0058-C

-8-

1-2. Installation/Piping

Warning

Installation location

- Please install the product in a location where pulsation is unlikely to occur.

When the difference between the inlet and outlet sides exceeds 0.1MPa, the element

might be broken.

- Install so that reverse pressure and back flow will not be generated.

Otherwise, the element might be broken.

Piping

- Connect piping/fittings using the recommended torque while holding the product

tightly.

Insufficient tightening torque can cause loose piping or sealing failure.

Excessive tightening torque can cause thread damage.

If the female side is not held while tightening, excessive force will be applied to the bracket

directly, causing breakage.

- Avoid excessive torsional moment or bending moment other than those caused by the

equipment's own weight as this can cause damage. External piping needs to be supported

separately.

Piping materials without flexibility such as steel tube piping are prone to be effected by

excess moment load and vibration from the piping side. Use flexible tubing in between to

avoid such an effect.

As a filter is a heavy object, please transfer or install it making sure that it will not be

dropped or dented.

Caution

Installation location

When installing, allow sufficient space for maintenance. (Refer to Dimension diagram

on P.19.)

- The piping of this product should be horizontal (drain exhaust should vertically face

downwards.)

If it is mounted inclined, laterally or upward/downward, the separated drainage will be

splashed over the outlet.

It may cause the operation failure of the auto drain.

- Pay attention to the dust generated from the air equipment which is mounted on the

outlet.

If the air equipment is mounted on the outlet of the filter, dust will be generated from the

equipment and cleanliness of the compressed air might be reduced. Consider the

mounting position of the air equipment in accordance with the required cleanliness of the

compressed air.

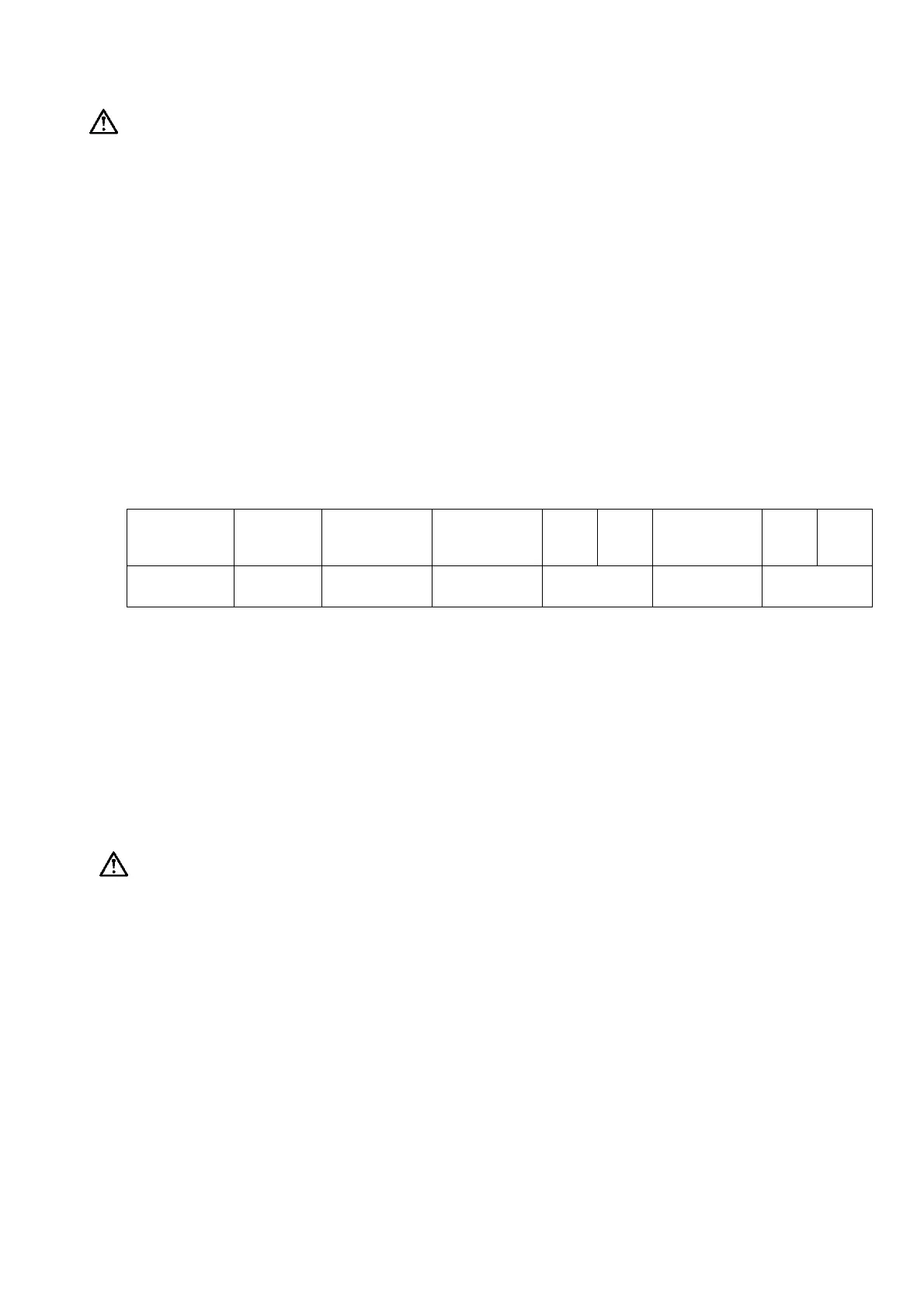

Recommended tightening torque (N・m)

Connection

thread

Port size

1/8 1/4 3/8 1/2 3/4 1 1

1/2

2

Tightening

torque

7 to 9

N・m

12 to 14

N・m

22 to 24

N・m

28 to 30

N・m

36 to 38

N・m

48 to 50

N・m

Loading...

Loading...