8 SERIES BOILER INSTALLATION AND OPERATING INSTRUCTIONS

Page 7

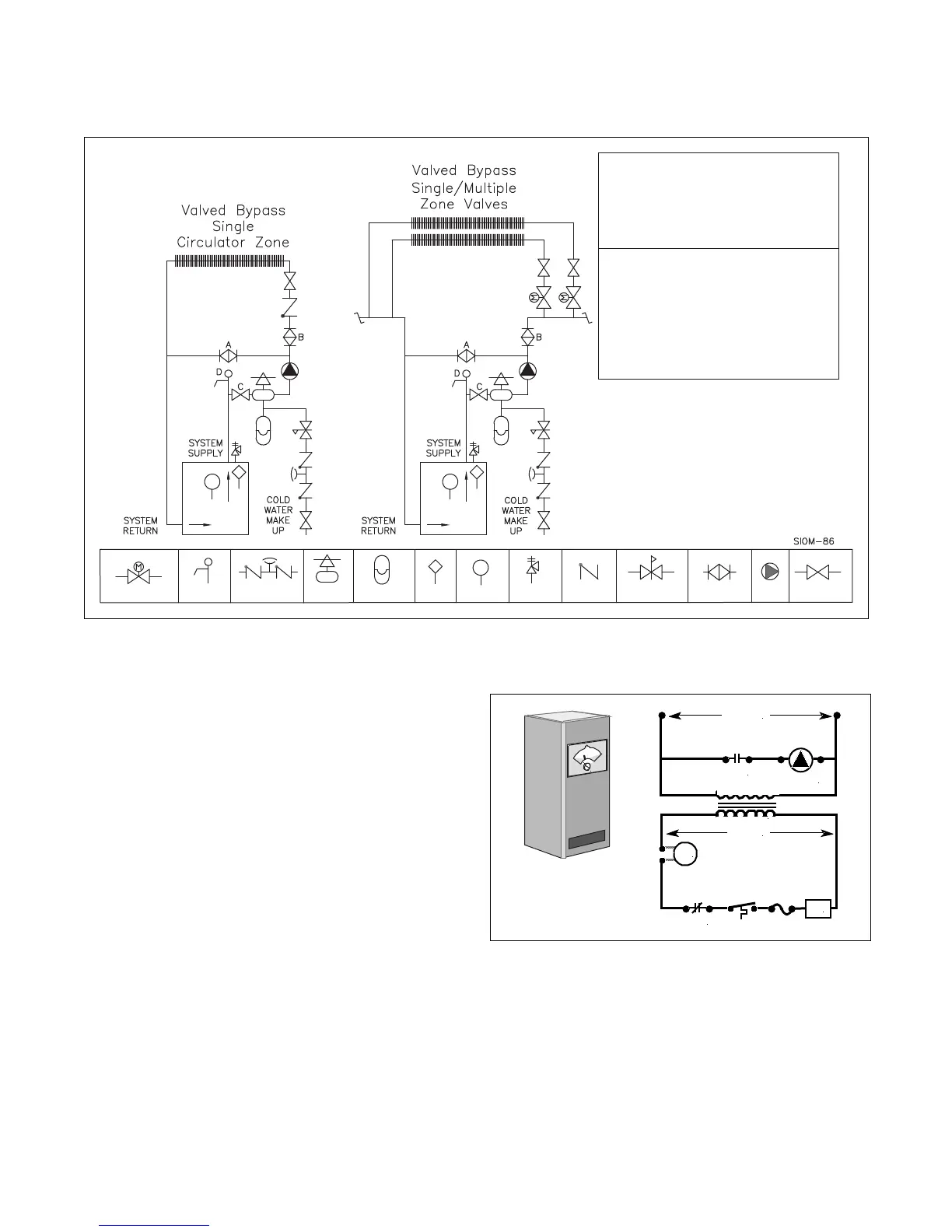

Reverse Acting Aquastats

There is an alternative for existing systems experiencing

condensation that does not require re-piping the boiler.

It is very effective on single zones high mass systems

with large water volumes and cast iron radiation. This

option utilizes a reverse acting aquastat, one that makes

on temperature rise. Wired in series with the circulator,

this control allows the burner to fi re while holding the

circulator off until the boiler reaches an acceptable

temperature. It then starts the system circulation again,

see Figure 7.

The most commonly available reverse acting aquastat is

a Honeywell L4006B. The aquastat should be mounted

in an immersion well directly installed in the boiler. The

use of heat conductive grease, Honeywell part #972545,

in the immersion well is strongly recommended for

fast and accurate temperature response. Set this

adjustable aquastat to make at no less than 130°F.

While this method can cause the circulator to cycle

more frequently, setting the aquastat’s differential to the

maximum 25-30°F will minimize short cycling.

Figure No. 7 – Reverse Aquastat

Each of these bypass solutions also has the added

benefi t of increasing circulation in the boiler which will

maximize tankless coil output and increase the accuracy

of temperature sensing controls.

reverse

aquastat

N.O.

T

T

t'stat

GV

115 volts

24 volts

circulator

operating

aquastat

N.C.

REVERSE

AQUASTAT

SET AT 130° F

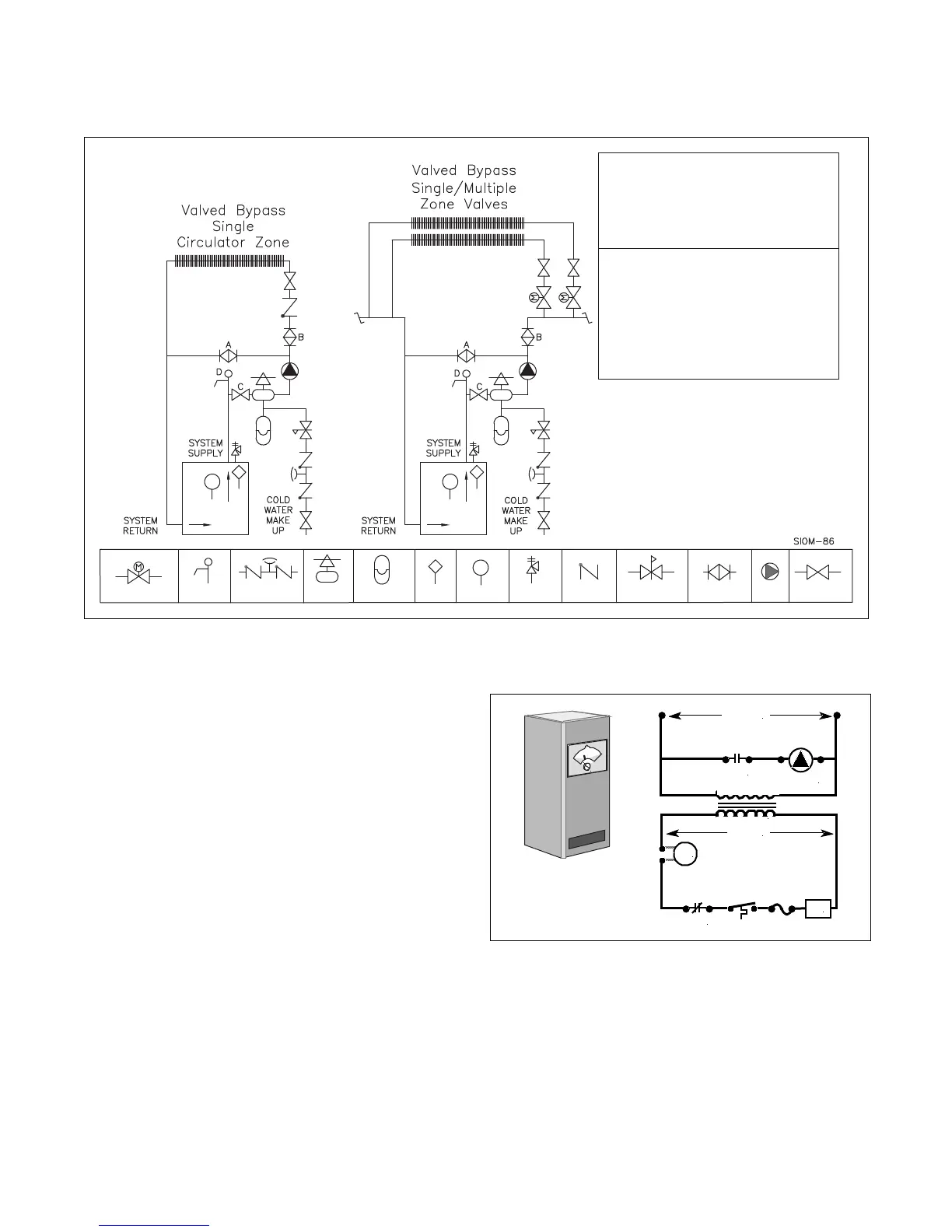

Figure No. 6 – Pump Away Bypass

Aquastat Thermometer

Reducing Valve

Pressure

Pump

Balance Valve

1. Turn boiler on and open valves A & B.

2. After steady-state operation, if T1 is less than 130° F

slowly close valve B until T1 climbs to desired operating

temperature above 130° F.

3. If T1 is greater than desired operating temperature, slowly

close valve A to adjust to lower desired temperature above

130° F.

4. Check after system operating temperature has

stabilized. Make final adjustments.

Bypass Adjustment Procedure To Maintain Inlet

Temperature Above Dew Point

T1=Temp Min=130° F

Backflow-Prevention

Device

Expansion

Tank

Pressure

Relief Valve

Check Valve

NOTES:

1. Boiler circuit piping must be sized large enough to handle

maximum flow through unit.

2. Boiler pump sized to boiler design flow requirements. A

percentage of the pump capacity is used for the bypass blend.

3. All boilers furnished with factory mounted water

temperature/pressure gauge.

4. A plug valve will offer the best flow control for the bypass. A ball

valve may not be suitable and may create noise.

Notice: These drawings show suggested piping configuration

and valving. Check with local codes and ordinances for

specific requirements.

Motorized Valve

Drain Cock

Ball or Gate

Valve

Air Vent &

Separator

System Purging.

1. Close valve A and C.

2. Attach a short hose to valve D and submerge in bucket of

water. Open Valve B and D.

3. Manually open the fill valve and use the domestic water

system pressure to purge air from each zone one at a time.

When air bubbles stop flowing from the hose close valve D.

4. Rest fill valve to automatic fill., and open valves A and C.

Loading...

Loading...