GENERAL INFORMATION

1.1. Application of the plate.

The GPC-2 type plate is a ceramic hob with 2 gas burners located underneath. This is the

newest generation of gas hobs where special gas burners controlled by an electronic system process

heat generated through gas combustion into infrared radiation. Radiation infiltrating the ceramic

plate heats the dishes positioned above the hot fields. Hot fields are indicated graphically on the

plate. This hob is provided with touch sensors for controlling its operations. It is fit for building in

a single kitchen countertop or in a combined countertop. It is designed for non-professional (home)

preparation of food and for household use.

Advanced solutions applied in the hob’s construction and design give it a nice esthetical

appearance while ensuring comfortable and safe use.

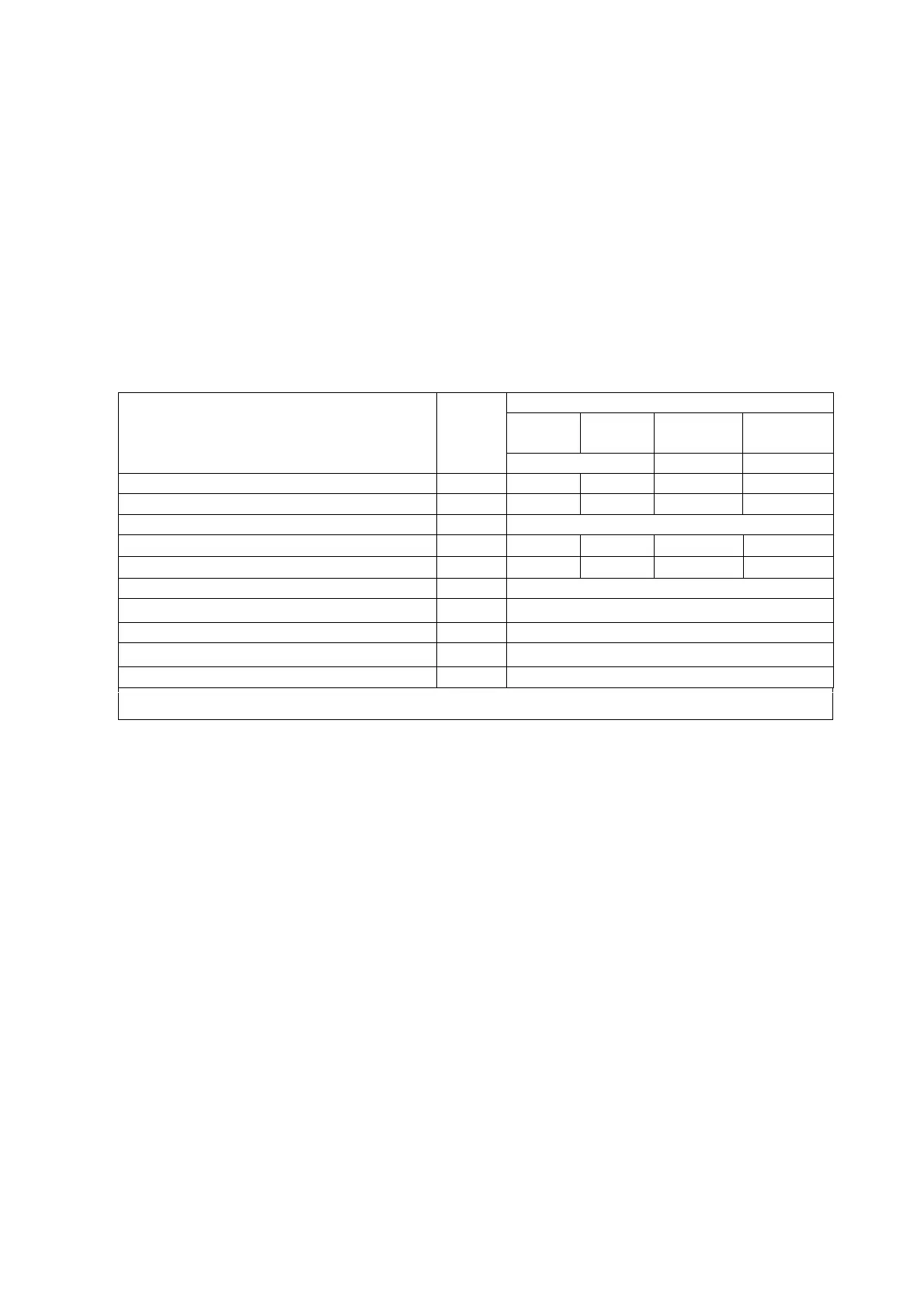

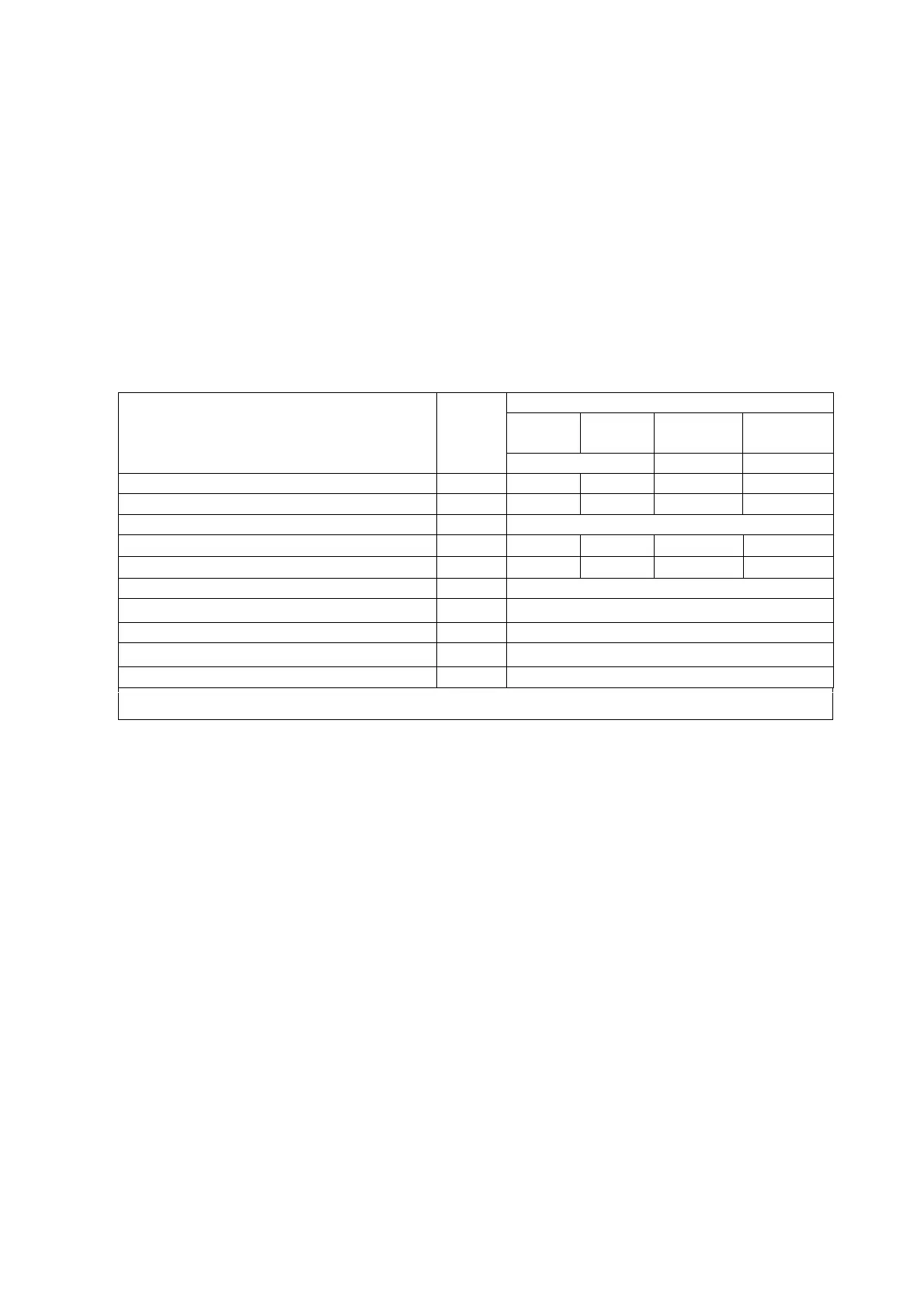

1.2. Technical data of the GPC-2 hob.

Table. 1

Gas nozzle of the f 90 (small) burner

Gas nozzle of the f 120 (medium ) burner

Rated heating power of the appliance

Rated heating power of 90 burner

Rated heating power of 120 burner

Power adapter supply voltage

Parameters of the power adapter

Protection class of the housing

The entire electrical installation of the hob is supplied with a special power pack and is prepared

as a low voltage system.

In terms of fire risk, the hob is classified as a safe device

1.3 Design of the gas hob

The hob (fig. 1) has two injector gas burners rated as specified in the table above, with a ceramic

insert, equipped with igniting electrodes and ionizing detectors of burning gas. Burners in which

catalytic combustion of gas takes place produce infrared radiation. They are covered with a

ceramic panel with four separate hot fields above the ceramic burners, indicated graphically on the

panel, and one hot pads above combustion gas ducts of gas burners, which do not consume gas.

Because the hob controls must be supplied with 12 VDC power, the hob is supplied from a 12V

power source via a special power pack to be connected to the 230V household system, included

with the delivered hob. Nozzles adapted to commonly used G 20 gas are installed in the delivered

hob by default. The gas source can be a gas network, or a liquid gas cylinder. Through replacing

the working nozzles according to Table 1 and changing the size of air diaphragm according to

Table 3, the user is able to adapt the hob to burning a different type of gas.

A touch control panel is located in the front part of the hob (fig. 1). It is for controlling and

regulating the specific gas burners of the hob. It also displays relevant messages of the cooker

operating conditions.

Loading...

Loading...