28

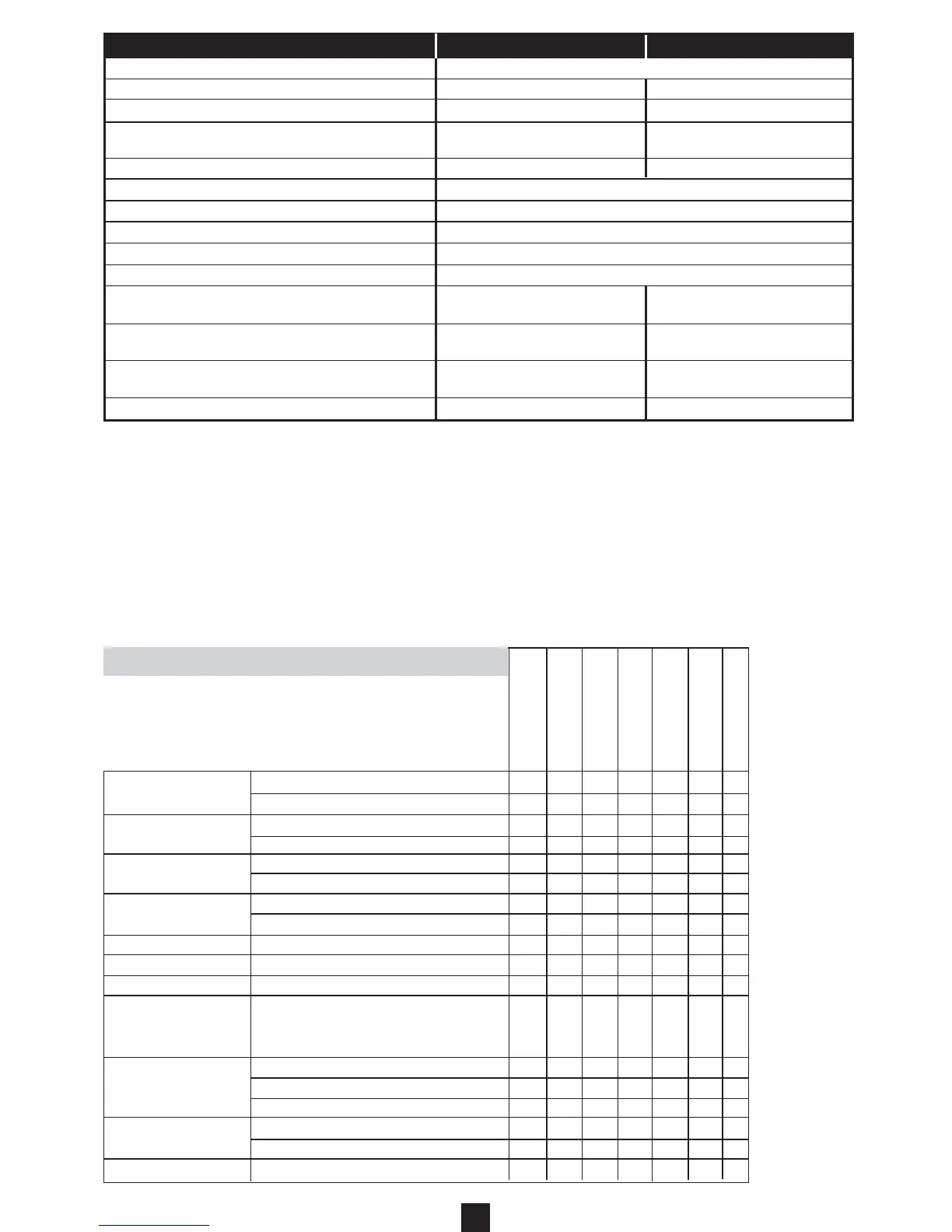

prior to work

check idle run

check adjustment

clean

replace

adjust electrode gap

replace

check

replenish

clean

clean

clean

re-tighten

check

sharpen

replace

check for proper operating

inspect

clean

daily

weekly

after 5 hrs

after 20 hrs

after 50 hrs

X

X

X

X

X

X

X

X

X1)

X

X

X

X

Service Schedule

(1) = one time

Carburetor

Air filter

Spark plug

Gear lubr.

Air intake

Cylinder fins

Fuel tank

All accessible screws

(except carburetor

adjusting screws)

Cutting blade

Grip

Compl. Brushcutter

on request

X

X

X

X

X

X

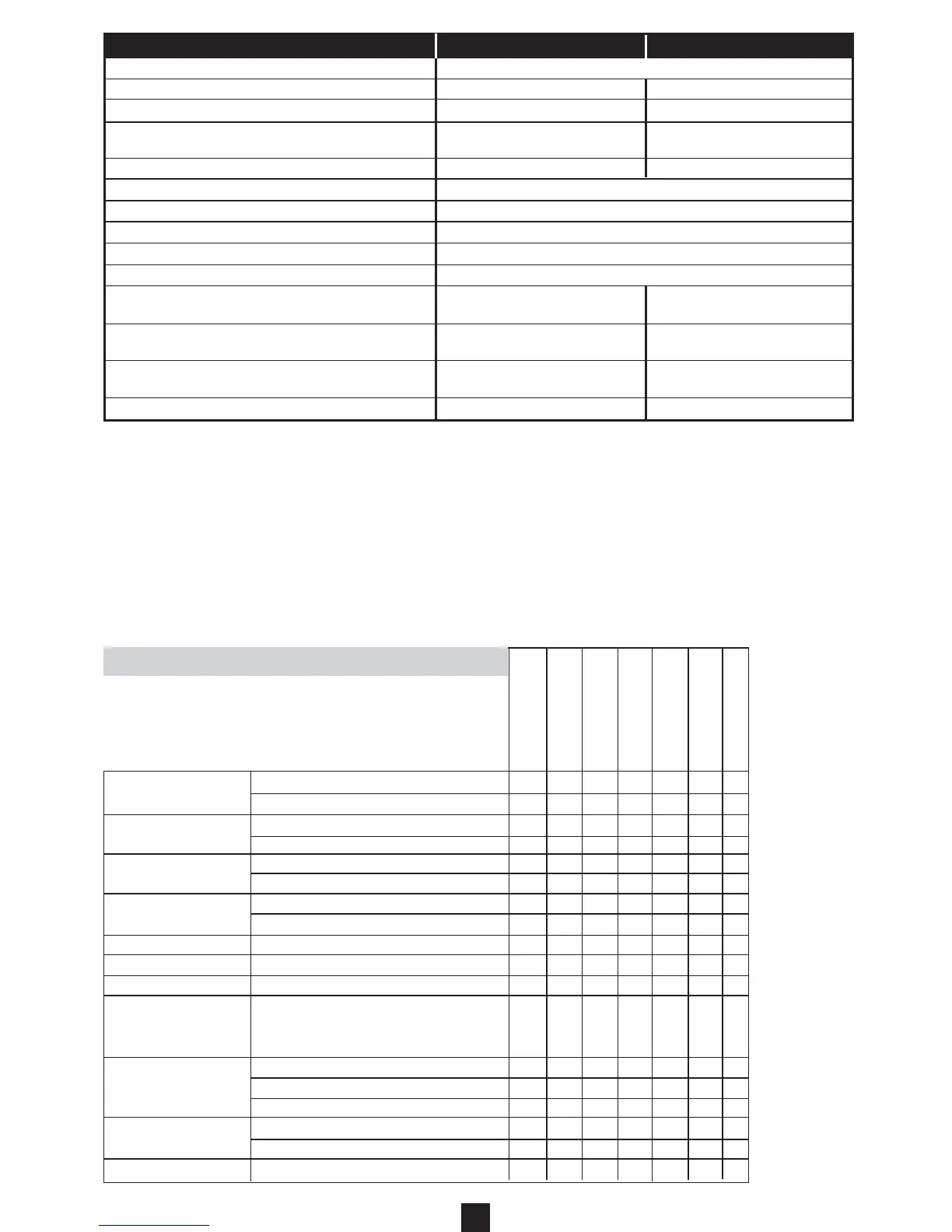

one-cylinder two-cycle engine

34

1.6 / 9500

9500

0.75

Brushcutting blade Ø 300 mm

95.1

108,5/110

Brushcutting blade Ø 300 mm 3.5

/ 3.9

7.2 (15.9)

Brushcutter

Engine

Capacity cm

3

Max. capacity with RPM per ISO 8893 kW/min

-1

Max. RPM unloaded w/ brushcutter min

-1

Gasoline tank amount liter

Carburetor

Gasoline

Air filter

Ignition

Gear head ratio

Noise level in work area L

PA

(EN27917)

dB (A)

Sound capacity level L

WA

(ISO 10884)

dB (A)

measured/garanted

Weighted acceleration value (ISO 7916)

right handle/left handle m/s

2

Weight without cutters kg (lbs)

Diaphragm carburetor with easy-start Primer-system

Gasline-oil-mixture

Foam filter

Electronic ignition

Spiral tooth gear 1,23 : 1

140

40

1.9/ 9000

9500

0.75

Brushcutting blade Ø 300 mm

94.8

108,5/110

Brushcutting blade Ø 300 mm 3.9

/ 5.0

7.3 (16.2)

134

* = Data provided is derived from equal parts of idling and maximum speed.

Loading...

Loading...