Preparing the equipment for use

ENGLISH 9

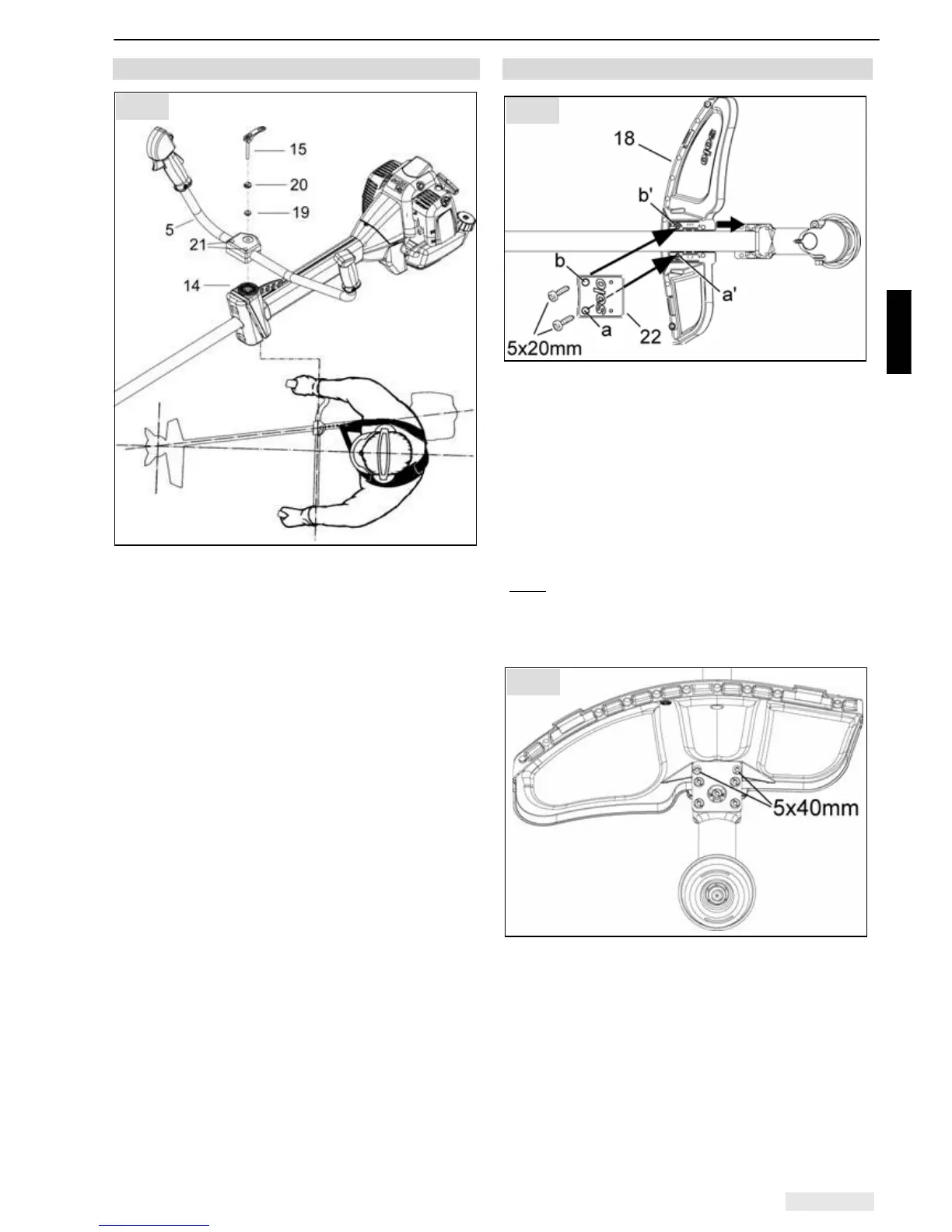

5.1 Installation - Bicycle handlebar

• Remove quick release screw (15) with sleeve (19)

and wavy washer (20) from the handle support

(14)

• Position the bicycle handlebar (5) with both pre-

assembled half shells onto the handle support

(14)

• Insert quick release screw (15) with sleeve (19)

and wavy washer (20) into the handle support, but

only so far that the quick release mechanism can

still flip over when the handle is sitting tight.

• The r.h. side of handle should be fitted as near as

possible to the handle support.

• For the optimum adjustment of the handle, flip

quick acting lock upwards and, if necessary,

release screws (21).

• Adjust the handle and flip quick acting lock (6)

back again.

• Now tighten screws (21).

Note: You will have achieved an optimum

adjustment, if the centre of the power tool is at the

centre of your body. Your elbow should be slightly

angled in operating position.

Important: Always lead the brushcutter with the

bicycle handlebar on the r.h. side of the body!

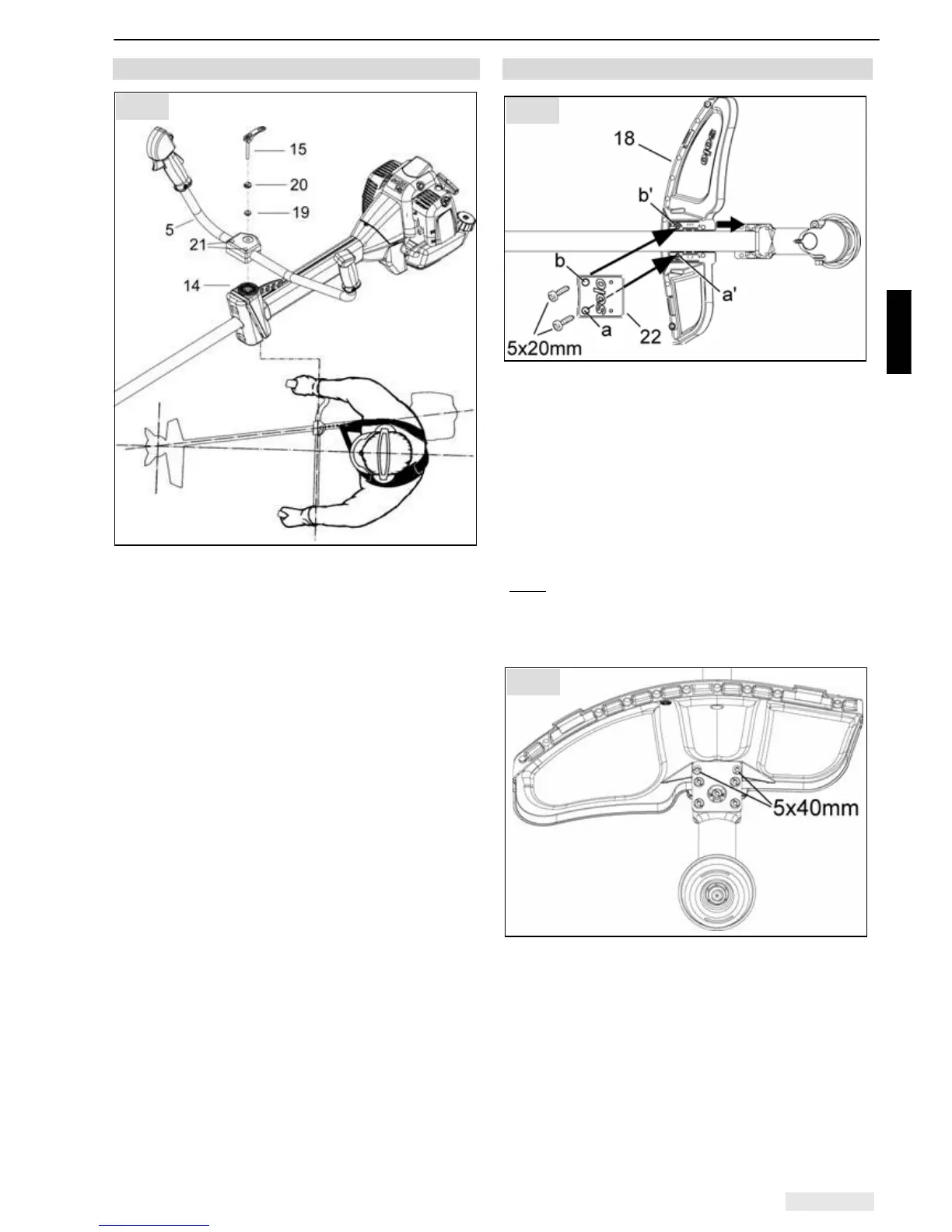

5.2 Shield installation

• Position the brushcutter with the output shaft

facing downward.

• Raise the shaft tube and slide the guard (18) along

the underside of the shaft tube into the correct

position (it should reach a stop at the angular

gearbox).

• Lay down the shaft tube with the guard.

• First insert a 5 x 20 mm bolt through hole a to

tighten the retainer (22) on the guard. Then insert

the second 5 x 20 mm bolt through hole b,

tightening finger tight only at this stage.

(Note:

The retainer has a raised part on the inside

near hole a. This allows the first bolt (which is

inserted through hole a) to be tightened straight onto

the block without any risk of the connection not being

straight.)

• Reposition the brushcutter with the output shaft

facing upward.

• Insert the two long 5 x 40 mm bolts through the

hole on the retaining bracket of the angular

gearbox and tighten the guard and the retainer.

The holes must line up exactly, so it may be

necessary to adjust the position of the guard first.

• To finish off, fully tighten the bolt in hole b.

Fig. 3

Fig. 2

Fig. 4

Loading...

Loading...