Commissioning

18

Safety instructions

CAUTION!

After installation of the operator, the person responsible

for the installation must complete an EC declaration of

conformity for the gate system in accordance with Machinery

Directive 2006/42/EC and apply the CE mark and a type plate.

This is also required for private installations and also

if the operator is retrofi tted to a manually operated gate.

This documentation and the installation and operating

manual are retained by the operator.

CAUTION!

The adjustment of the force tolerance is safety-relevant and

must be performed by qualifi ed personnel with the utmost

care. If the adjustment of the spring unit is excessively high,

people or animals could be injured and objects damaged.

Select a force tolerance that is as low as possible so that

obstacles are detected quickly and safely.

CAUTION!

Always perform learning run under supervision, because

the operators traverse at full power. This is dangerous for

persons, animals and object within the range of motion of

the gates.

CAUTION!

Before working on the gate or the operator always disconnect

the control unit from the power supply and lock to prevent

reactivation.

“WL” LED and a connected warning light (accessory) fl ash during

the learning run and as a visual warning at standstill.

In the commissioning process the force required for opening and

closing, the runtime and the closing delay are learned and saved

by the control unit.

Preparing continuous operation

IMPORTANT INFORMATION!

Do not use a metal object to set the DIP switches, because

this may damage the DIP switches or the circuit board.

The DIP switches can be set with a narrow, fl at plastic object.

• Components for 1- or 2-leaf gate are connected and set, see chapter

“Functions and connections”.

• Mains power is connected and voltage (AC 230 V) is present at control

unit: “Mains” LED on.

• The fi ttings bolts are tightened, operators can be moved easily.

1. Position cover and click into place.

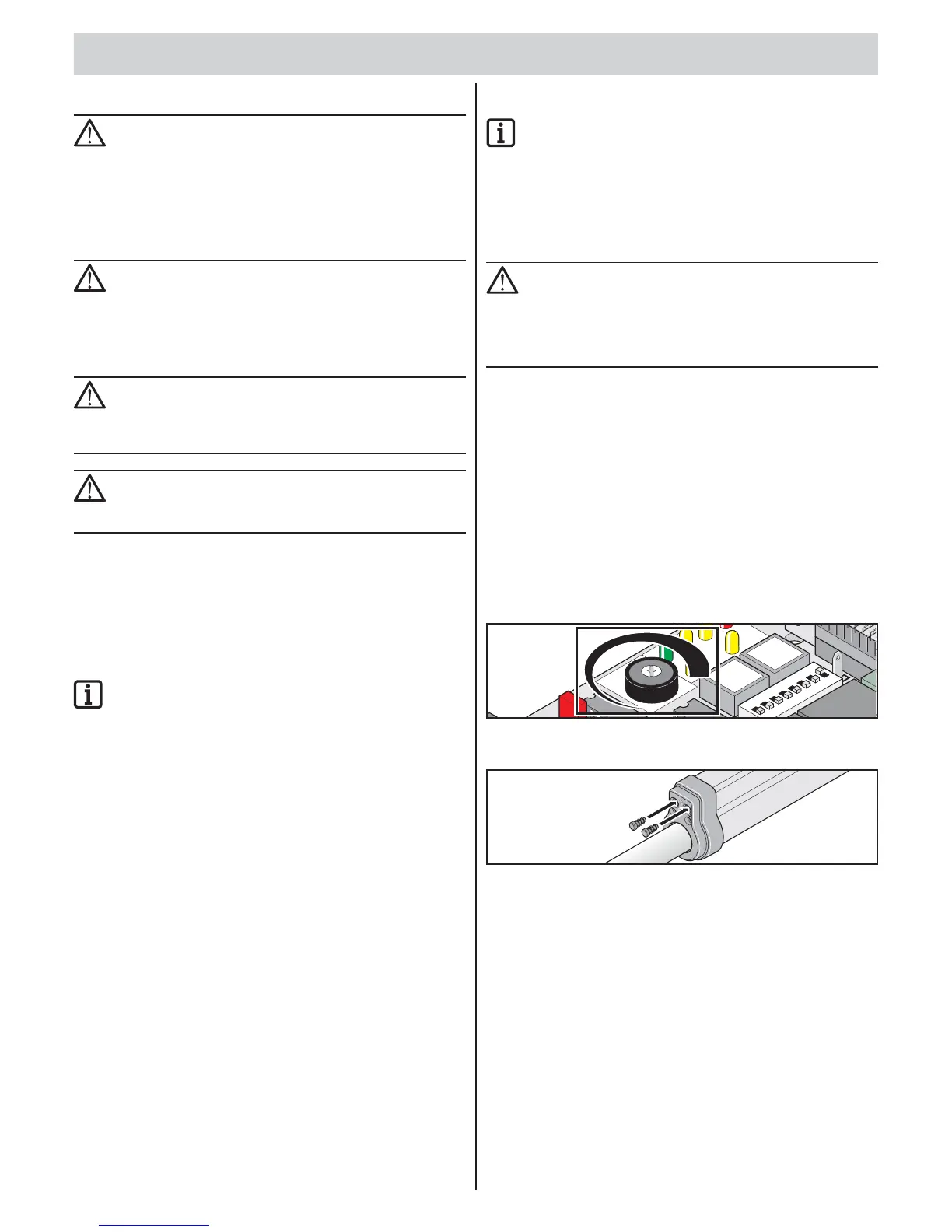

2. Set emergency unlock and lock with padlock.

3. Close the gate.

4. Check jumper setting for 1- or 2-leaf operation, see “Jumper” chapter.

Adjusting the force tolerance

IMPORTANT INFORMATION!

After installation of the operator the person responsible for

installation of the operator must issue an EC Declaration of

Conformity for the gate system in accordance with Machinery

Directive 2006/42/EC and attach the CE symbol and a type

plate. This is also required for private installations and also

if the operator is retrofi tted to a manually operated gate.

This documentation and the Installation and Operating

Instructions are retained by the operator.

CAUTION!

The adjustment of the force tolerance is safety-relevant and

must be performed by qualifi ed personnel with the utmost

care. If the adjustment of the spring unit is excessively high,

people or animals could be injured and objects damaged.

Select a force tolerance that is as low as possible so that

obstacles are detected quickly and safely.

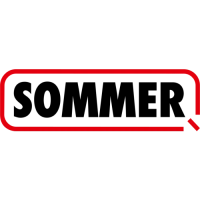

• Maximum force = learned force + force tolerance

(adjustable with the potentiometer).

• If the force is not suffi cient for opening or closing the gate completely,

increase the force tolerance by rotating the potentiometer clockwise.

• If the setting is changed while the gate is opening or closing,

the control unit imports the setting next time the gate is opened.

• After setting the force tolerance it may be necessary to reset

the end positions.

Checking force tolerance

See Care and maintenance/regular testing.

Setting the force tolerance to the automatically learned force.

The potentiometer setting is imported again at every start.

L

E

D

1

L

E

D

2

L

ED 6

L

E

D

4

LE

D

5

L

ED

3

Loading...

Loading...