0739P310 IG_Installation Guide Supercal 739_V01_2006_en_de_fr_it 3 Sontex SA, 2605 Sonceboz, Schweiz, Suisse

Installation guide Supercal 739

The compact mechanical single or multiple jet thermal energy meter Supercal

739 is a precision measuring instrument approved for individual metering of

heating systems. It must be handled with care.

The Supercal 739 is available in a heating or cooling version and determines the

thermal or cold energy exchanged by a heat-bearing fluid in a heat exchanger

circuit.

The Supercal 739 complies with the requirements of the European Directive

MID 2014/32/EU modules B and D and of the standard EN 1434 class 3.

Important

The energy meter may only be used under the conditions indicated on the manu-

facturer’s rating plate! The seals must not be removed or may be removed only

by authorised persons.

If these conditions are disregarded, the warranty and the calibration will no longer

be the manufacturer’s responsibility.

Do not shorten the cable between the flow meter and the integrator and the

cables for the temperature sensors or modify them in any way whatsoever.

Before installation

Check the installation data and compare them with the specific characteristics of

the thermal energy meter.

Installation

The related prescriptions in the standard EN1434-6 must be respected when

installing the Supercal 739.

Depending on version and use (heat and/or cooling meter), the energy

meter must be fitted on the “cold” or “hot” pipe side of the installation in

compliance with the indications showed on the LCD display, service menu

and/or config menu (if available).

Place the flow meter according to the direction of the fluid (an arrow is visible

on the flow meter).

The energy meter must be fitted between two shutoff valves and ahead of any

monitoring valve to avoid any interfering influence.

Mixed mounting positions (horizontal and vertical) should be avoided in any

installation!

Final commissioning is recommended and documented.

For all further information such as for example settings for radio transmis-

sion, please refer to the detailed User manual of the Supercal 739 heat

meter available at:

The QR code located on the label of the carton or

on the integrator allows to access to the Installation

Manual on a smartphone.

Wall-mounting of the integrator

The integrator can be separated from the flow meter and fixed against a wall

using the wall fixture supplied with the energy meter, possibly above the flow

meter.

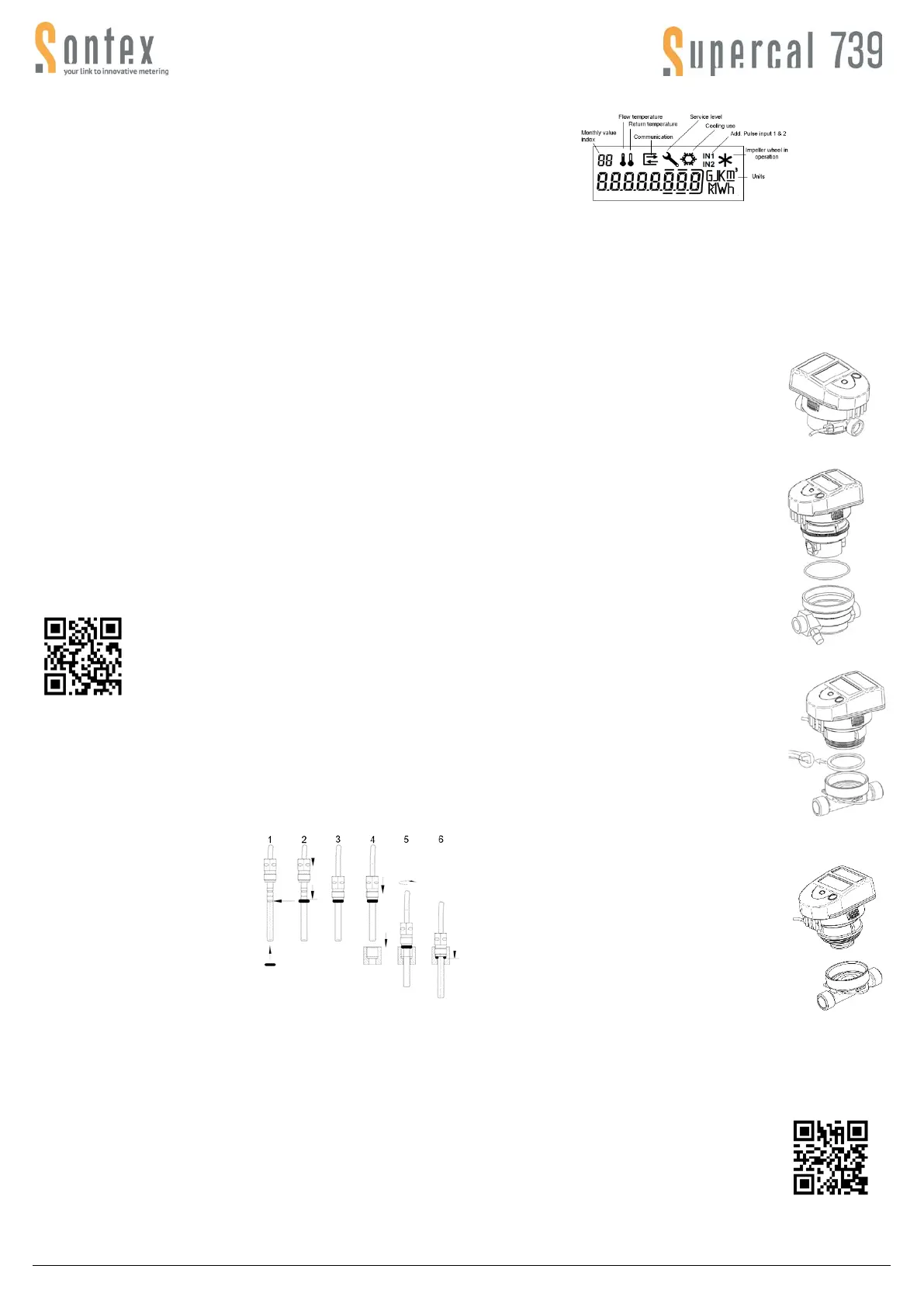

Mounting the temperature sensors

The temperature sensor with a colourless marking is fitted close to the flow meter

or directly into it. The temperature sensor cable marked with an orange label is

mounted in the “opposite” pipe (in the other side of the heat exchanging circuit) of

the one with the Supercal 739.

Check whether the O-ring is in the

3rd groove (arrow)

1. If not, push the O-ring into the

corresponding groove

2. Push the screw connection up to

the O-ring

3. Insert the temperature sensor into

the tube fitting

4. As soon as the O-ring is in contact

with the thread, screw in the

temperature sensor by hand

up to the stop

5. Then tighten with a maximum tightening torque of 1.4 Nm (corresponds to

approx. one ½ turn)

Asymmetrical mounting is also possible. In that case the temperature sensor

having a cable marked with orange will be fitted in the other side of the heat

exchanging circuit in a sensor pocket.

For applications with non-symmetrical integrated temperature sensor pair re-

stricted rated operating conditions are to be in accordance with the lower limit of

the flow value and the lower limit of the temperature difference:

qi ≥ 200 l/h at ∆T

min

= 3K or qi ≥ 60 l/h at ∆T

min

≥ 6 K.

Make sure that the sensor is mounted until they stall with the bottom of the sen-

sor pocket.

Error codes

Err 1: Flow higher than 1.2 x qs or defective hydraulic sensor.

Err 2: Measured temperature outside the homologated range or temperature

sensor defective.

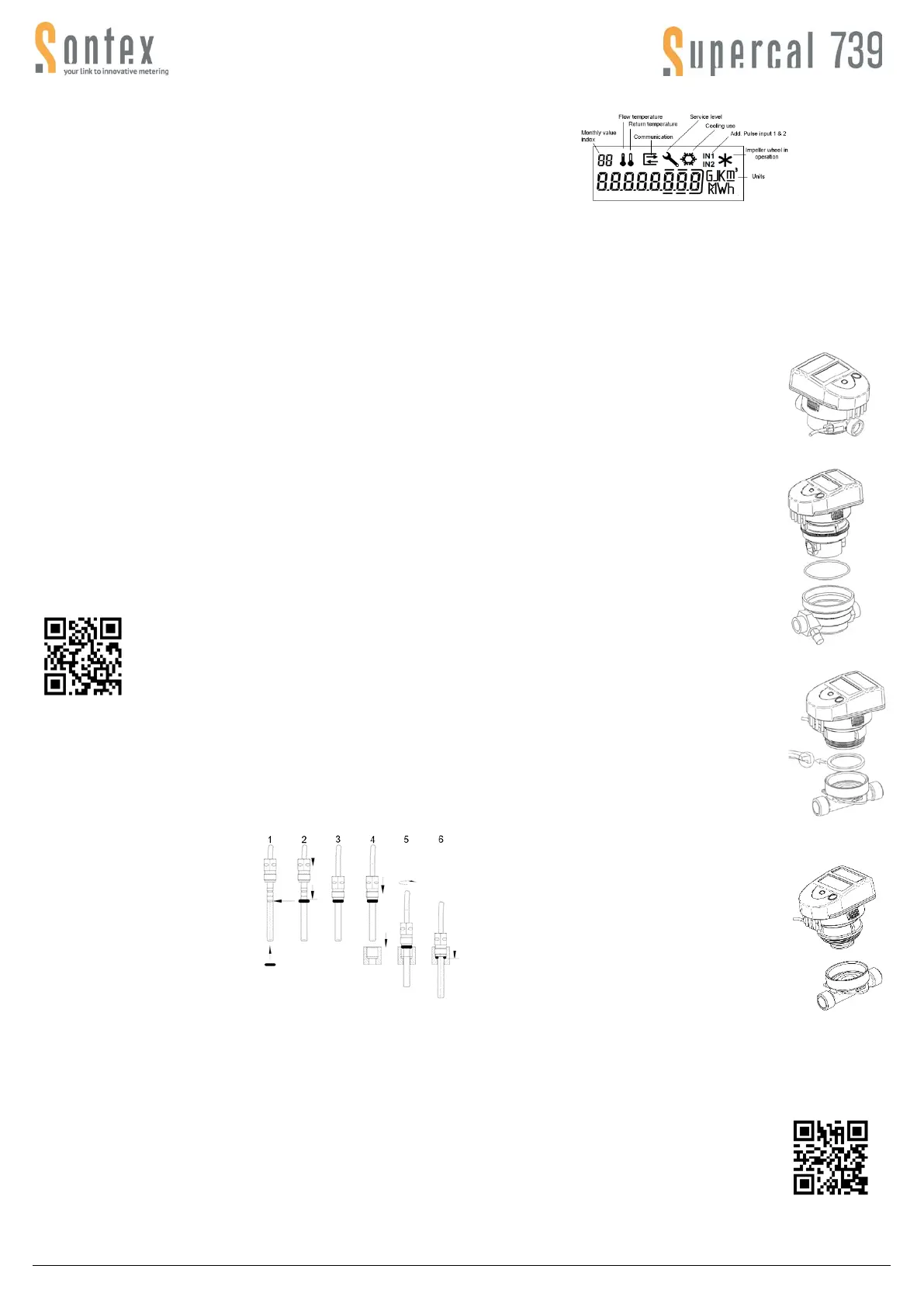

Display

The Supercal 739 LCD display has been designed to be large enough and per-

fectly readable by the user.

“Disabled” on the display means that the device is in the storage mode and

doesn’t count any Energy/Volume. In order to activate it refer to the User

Manual.

Mounting and metering activation procedure

1. Flush out the installation pipes carefully

2. Close the shutoff valves before and behind the meter.

3. Open the drainage valve to reduce the pressure and discharge the water

contained in the pipe.

4. Consider the direction of the flow

1. Place a gasket on each side of the flow meter. Only

use appropriate new gaskets.

2. Tighten the fixing nuts firmly by hand. Then tighten

up to the mechanical end stop using a mounting tool.

3. Turn the display into the desired position for reading.

4. Check the waterproofness of the meter placed under

pressure.

Coaxial multi jet meter with M77x1.5 connection

1. Remove the blind cover or the old meter from the

EAS base using an installation spanner.

2. Remove the pre-formed gasket then clean the

contact surfaces and the thread.

3. Place the new o-ring in the EAS base. Make sure

that the o-ring is correctly positioned.

4. Lubricate the external thread (M77x1.5’) of the

metering capsule with a fine silicone coating.

5. Lay the capsule in the base. Important! Make sure

that the blind hole in the metering capsule is cor-

rectly positioned in the base.

6. Screw the measuring capsule down firmly by hand,

then tighten as far as the mechanical end stop us-

ing a mounting tool.

Coaxial multi jet meter with G2’’ connection

1. Remove the blind cover or the old meter from the

EAS base using an installation spanner.

2. Remove the pre-formed gasket and then clean the

contact surfaces and the thread.

3. Place the new profiled gasket in the EAS base with

the plane surface facing upwards or the groove in

the preformed gasket facing downwards. Make sure

that the gasket is properly positioned.

4. Lubricate the external thread (G2’’) of the measur-

ing capsule with a fine silicone coating.

5. Screw the measuring capsule down firmly by hand.

Then tighten as far as the mechanical end stop us-

ing a mounting tool.

Coaxial multi jet meter with M62x2 connection

1. Remove the blind cover or the old meter from the

EAS base using an installation spanner.

2. Lubricate the external thread of the measuring

capsule with a fine silicone coating.

3. Screw the measuring capsule down firmly by hand.

Then tighten as far as the mechanical end stop us-

ing a mounting tool.

5. Turn the display into the desired position for reading.

6. Seal the flow meter, the measuring capsule and the temperature sensors.

When in storage mode (“Disabled” is displayed) activate the meter by long press-

ing the orange button (if config menu available, configure first).

CAUTION: this action is irreversible!

Declaration of conformity: The detailed certificate of

conformity can be consulted on the Sontex website:

www.sontex.ch or by scanning the following QR code:

Loading...

Loading...