– 11 –

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belts capstan

2. Demagnetize the playback head with a head demagnetizer.

(Do not bring the head demagnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage (1.3 V) unless otherwise noted.

Torque Measurement

Mode Torque Meter Meter Reading

(1.47 – 2.94 mN•m)

FWD 15 – 25 g•cm

CQ-102C

(0.22 – 0.36 oz•inch)

(0.029 – 0.196 mN•m)

FWD

0.3 – 2.0 g•cm

Back Tension

(0.004 – 0.01 oz•inch)

(1.47 – 2.94 mN•m)

REV 15 – 25 g•cm

CQ-102RC

(0.22 – 0.36 oz•inch)

(0.029 – 0.196 mN•m)

REV

0.3 – 2.0 g•cm

Back Tension

(0.004 – 0.01 oz•inch)

(more than 3.43 mN•m)

FF, REW CQ-201B more than 35 g•cm

(more than 0.5 oz•inch)

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Specified voltage : 1.3 V (DC)

2. Switch position

VOL, AVLS : Center

3. Remote control setting

HOLD switch : OFF

VOL knob : MAX

DOLBY NR : OFF

SOUND mode : Normal

0 dB=0.775 V

Test tape

Type Signal Used for

WS-48A 3 kHz, 0 dB Tape Speed Adjustment

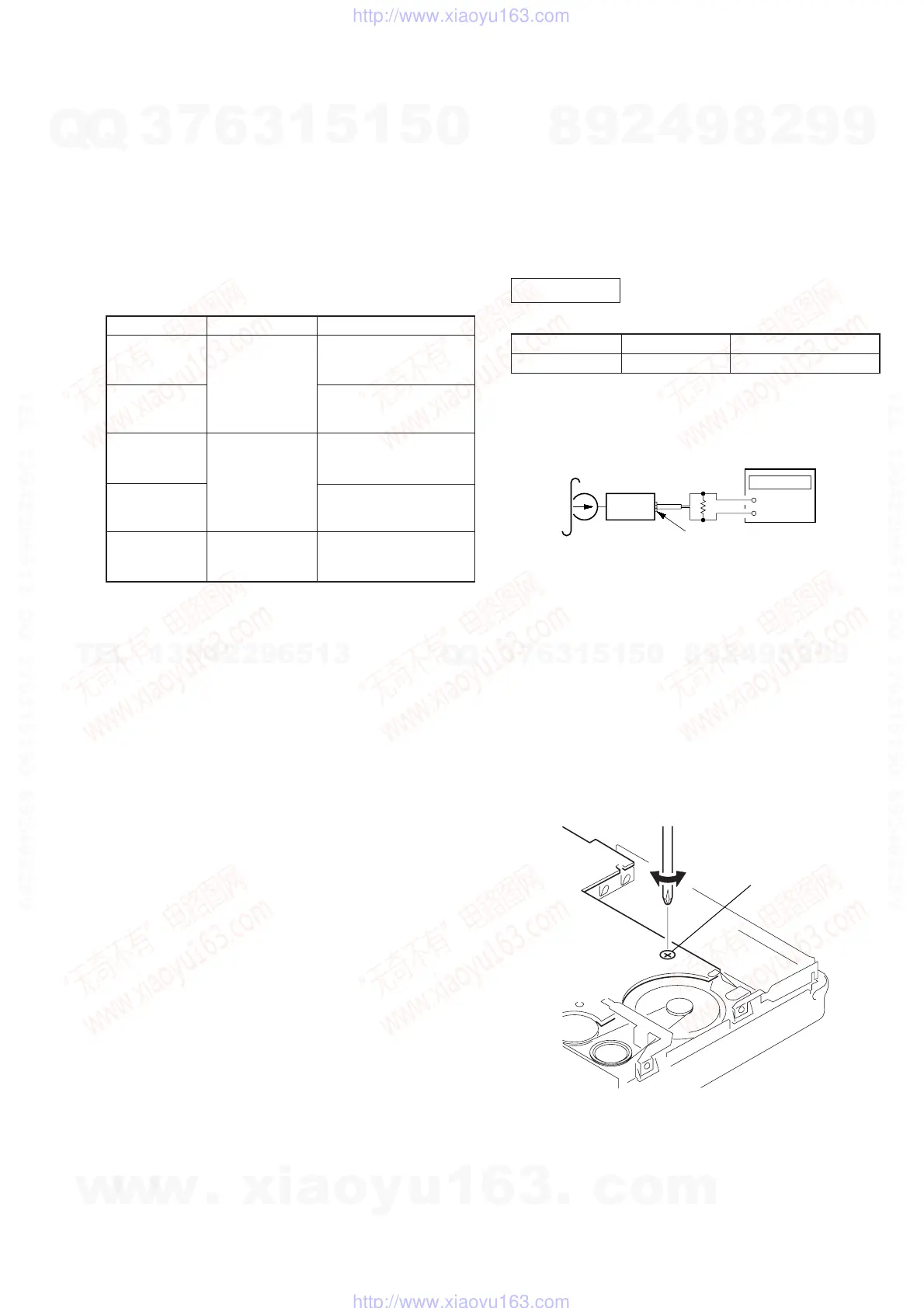

Tape Speed Adjustment

Setting:

Procedure:

1. Playback WS-48A (tape center) in the FWD state.

2. Adjsut RV601 so that the frequency counter reading becomes

3,000 Hz.

Specification Values: 2,985 to 3,015 Hz

3. Playback WS-48A (tape center) in the REV state.

Check that the frequency counter reading is within 2.0%

(approx.60 Hz) of the reading of step 1.

Adjustment Location:

– MAIN BOARD –

frequency counte

test tape

WS-48A

(3 kHz, 0 dB)

set

i

jack (J301)

–

+

16

Ω

RV601

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com

Loading...

Loading...