Page 11 of 23 Guide for Installation and use of Southwire C

7

Overhead Conductor

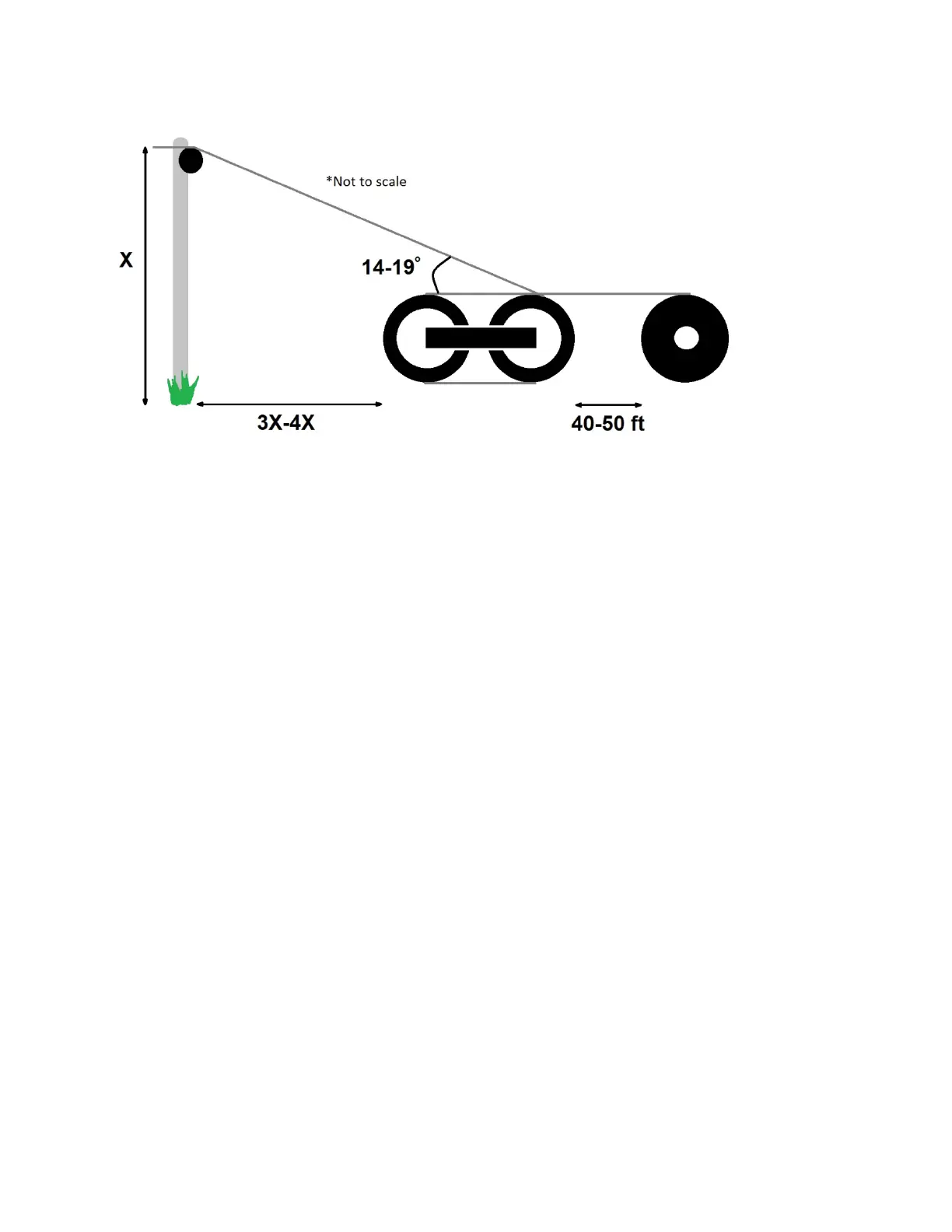

Figure 12: Orientation for bullwheel/payoff setup.

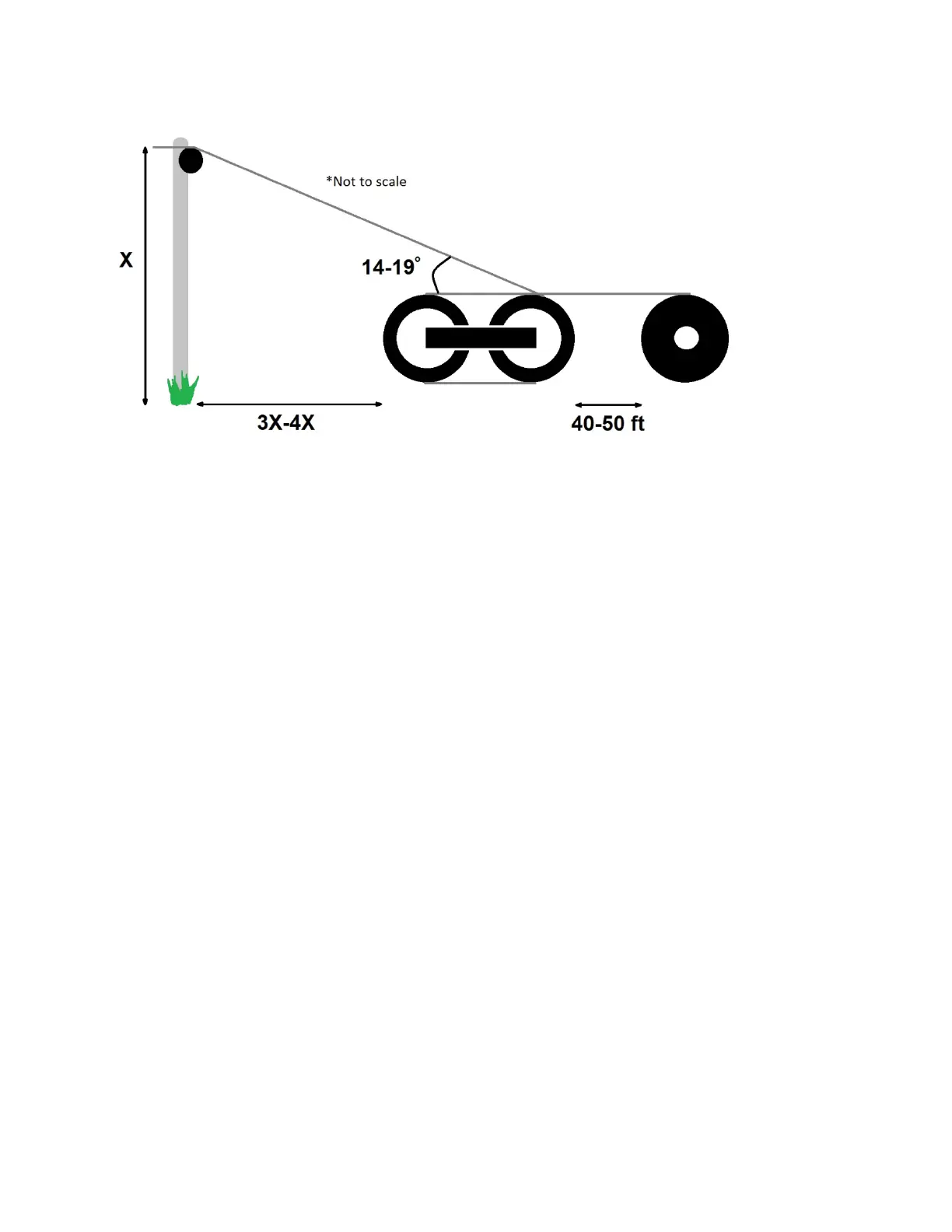

Stringing Sheaves

A minimum bottom groove diameter of 20 times the conductor diameter is recommended for

partial turns (less than 20°). For entrance blocks and pulls with a structure offset greater than

20°, this diameter needs to be increased to 30x conductor diameter. For straight line tangent

structure blocks, the bottom groove diameter requirement may be relaxed to 20 times the

conductor diameter minus 4 in (10 cm). Measurement A in Figure 13 below shows where to

measure the bottom groove diameter.

The minimum radius at the base of the groove is recommended to be 1.1 times the radius of

the conductor. The location of this measurement is shown as Measurement B in Figure 13.

Sheaves with a groove radius as above may, in general, be used with smaller conductors.

However, the more layers of aluminum that exist, the more important it is to have a well-fitting

groove.

The minimum depth of the groove should be 1.25 times the conductor diameter. This

measurement is given as Measurement C in Figure 13. The flare of the grooves should be

between 12-20° from vertical to facilitate the passage of swivels, grips, etc., and to contain the

conductor for angled pulls.

Loading...

Loading...