Page 16 of 23 Guide for Installation and use of Southwire C

7

Overhead Conductor

Other grips may be determined to be applicable for use with C

7

. Any grips should be qualified

by the manufacturer for use with C

7

and should be tested prior to use. Do not use grips that are

not specifically authorized for C

7

. Some designs, and especially range-taking grips, will transmit

excessive crushing forced to the core and could cause damage.

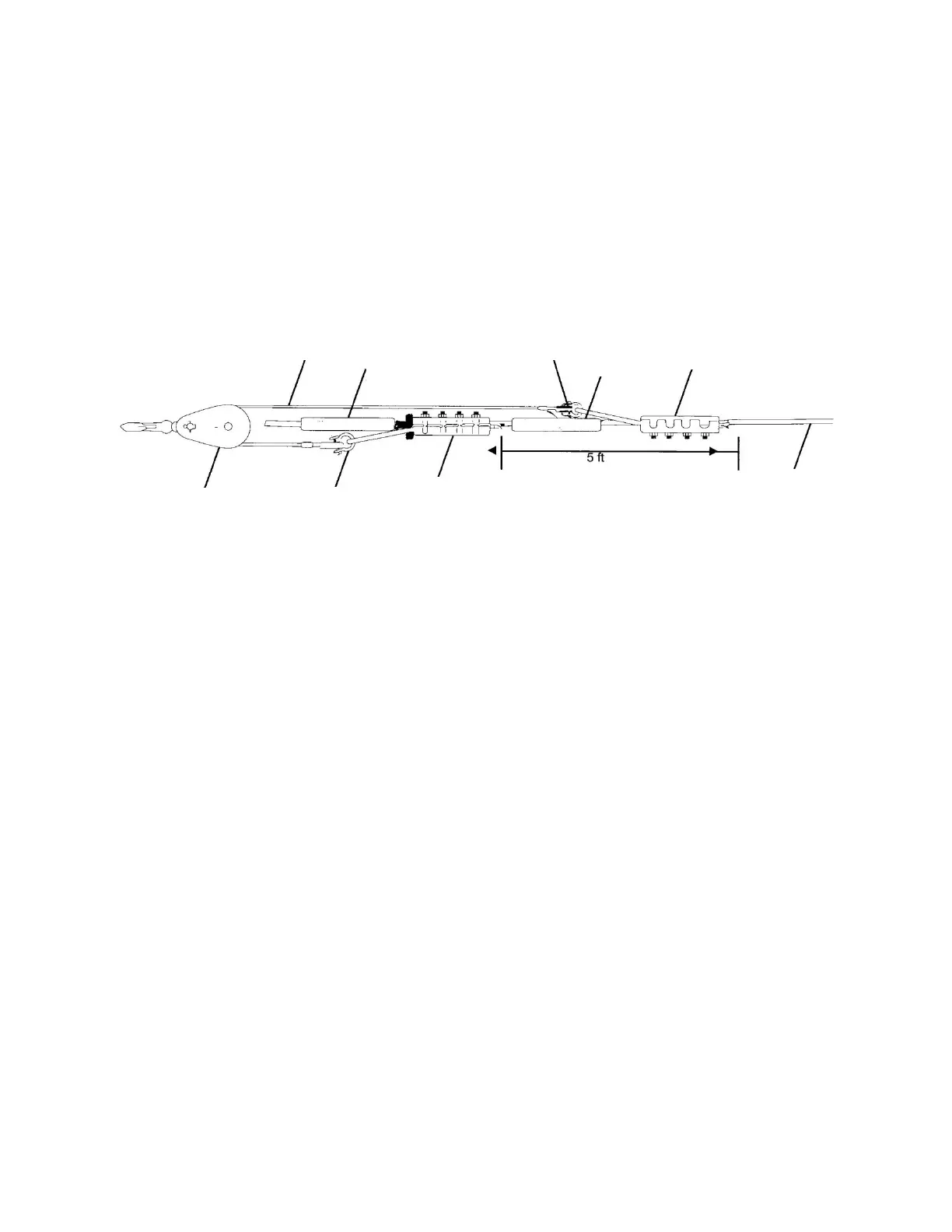

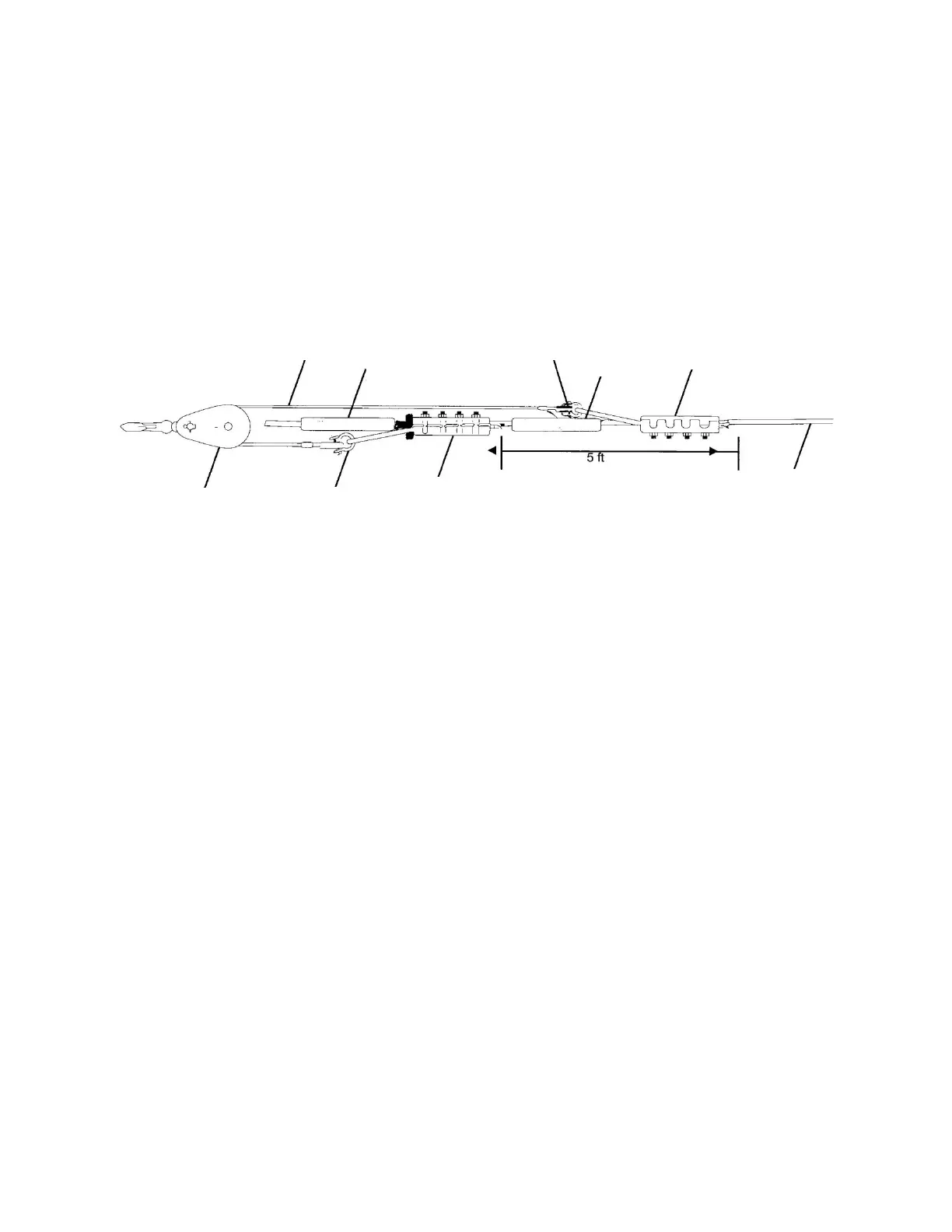

For pulling tensions above 5000 lb (22 kN), a tandem gripping arrangement is needed to avoid

excessive force on one grip. Figure 18 illustrates the tandem-gripping arrangement, which may

be used with both pocketbook and Klein style grips.

Figure 18: Tandem pocketbook-style grip configuration (also applicable to Klein grips).

Splice, Dead End, and Tap Connectors

As of publication of this guide, AFL® two-piece compression and PLP® formed-wire hardware

are qualified for C

7

conductor. Approval for each is on a case-by-case basis and depends on the

conductor size and construction.

Fittings for C

7

are similar to hardware for ACSS, but the size is larger to handle high tension and

high operating temperatures. For formed wire fittings, ACSR and ACSS hardware may fit, but

only hardware marked for C

7

conductor will perform up to the full conductor capacity. For two-

piece compression fittings, only hardware approved and marked for C

7

should be used. Bolted

T-taps and wedge-type clamps are suitable pending hardware manufacturer approval.

Bolted deadends (strain clamps), implosion connectors, and automatic splices are not qualified

for use on C

7

. H-frame and parallel-groove (PG) tap connectors are not recommended.

Implosive splices have not been tested on C

7

as of this publication. Check with Southwire or

your hardware manufacturer for a recommendation on usage of alternative fittings on C

7

conductors.

sleeve

sleeve

Loading...

Loading...