Page 12 of 23 Guide for Installation and use of Southwire C

7

Overhead Conductor

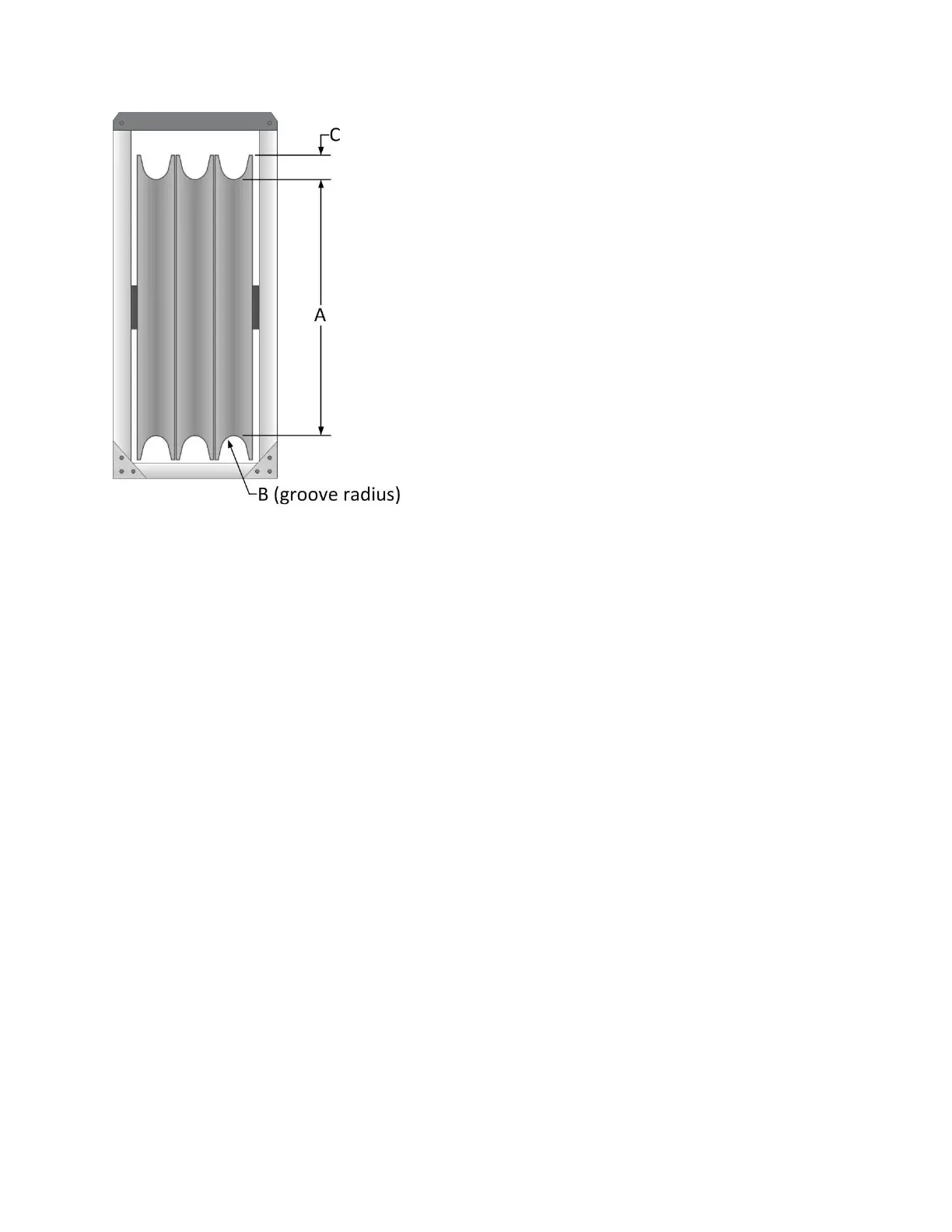

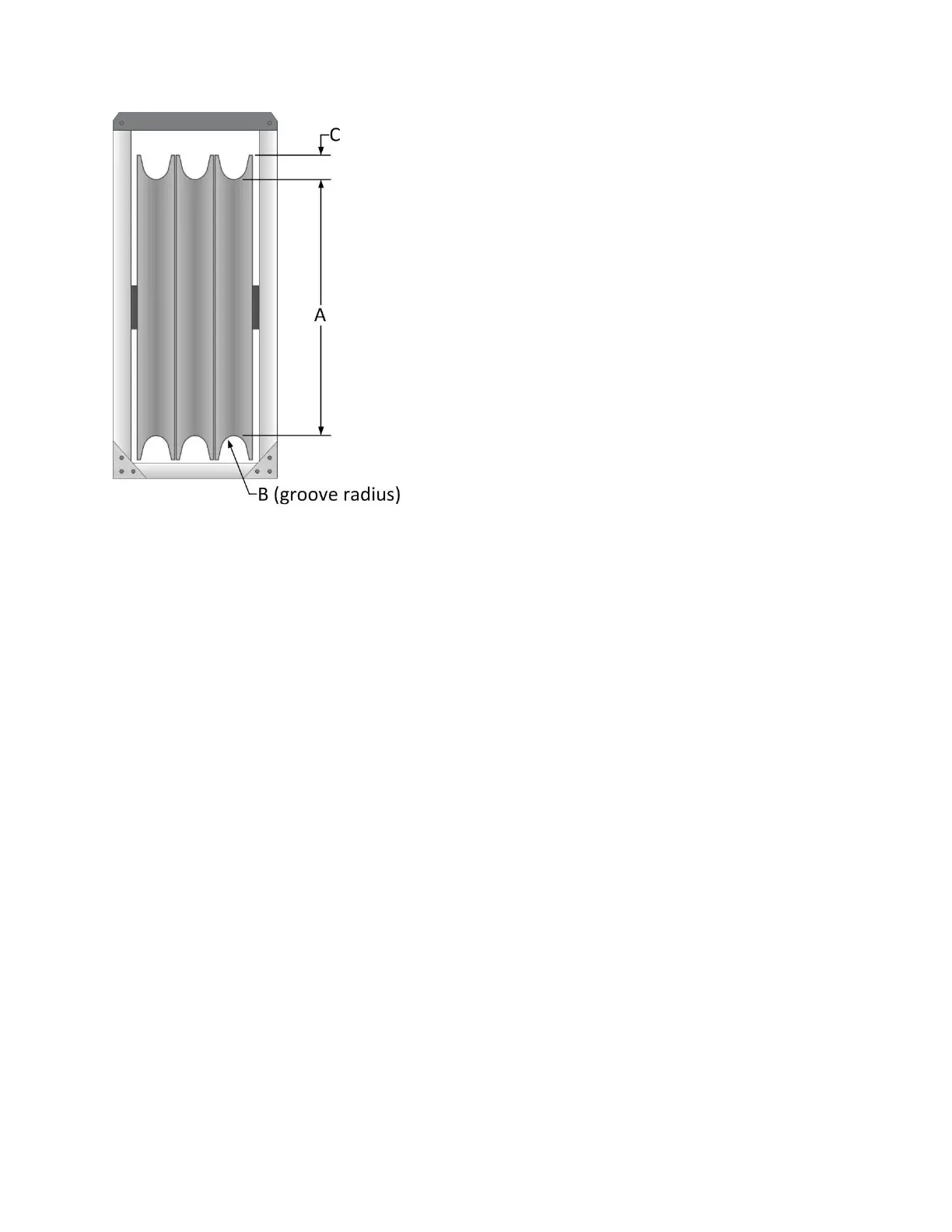

Figure 13: Measurements for stringing sheave.

Sheaves should be lined with neoprene or polypropylene to increase bearing area and protect

against scratching of the conductor. Sheaves must be free-wheeling. Rough handling of sheaves

can result in inadequate performance, so make sure all sheaves are in proper working order

before use.

Running Grounds

Running grounds should be installed along two points in the pull—one between the reel stand

or tensioner and first structure, and the other between the puller and last structure. Running

grounds should be bonded to the established ground and free-wheeling. They should not be

over tightened, as this could cause surface abrasion or birdcaging. Also note the caution about

using a rope to pull the conductor down for installation of grounds.

Conductor Stringing and Sagging

To avoid damaging the conductor, tension stringing is recommended. The maximum

recommended pulling tension during the stringing operation should not exceed that necessary

to maintain clearances above obstructions on the ground or safety structures. Recommended

stringing tensions are between 5-10% of the rated breaking strength of the conductor and must

never exceed 50% of sagging tensions. Recommended pull speeds are between 2 to 5 mph (5-8

kilometers per hour).

Any conductor that is to be left in the sheaves for an extended period of time can be damaged.

Since it is not secured, weather and other factors can cause slack to move from sheltered span

Loading...

Loading...