Page 6 of 23 Guide for Installation and use of Southwire C

7

Overhead Conductor

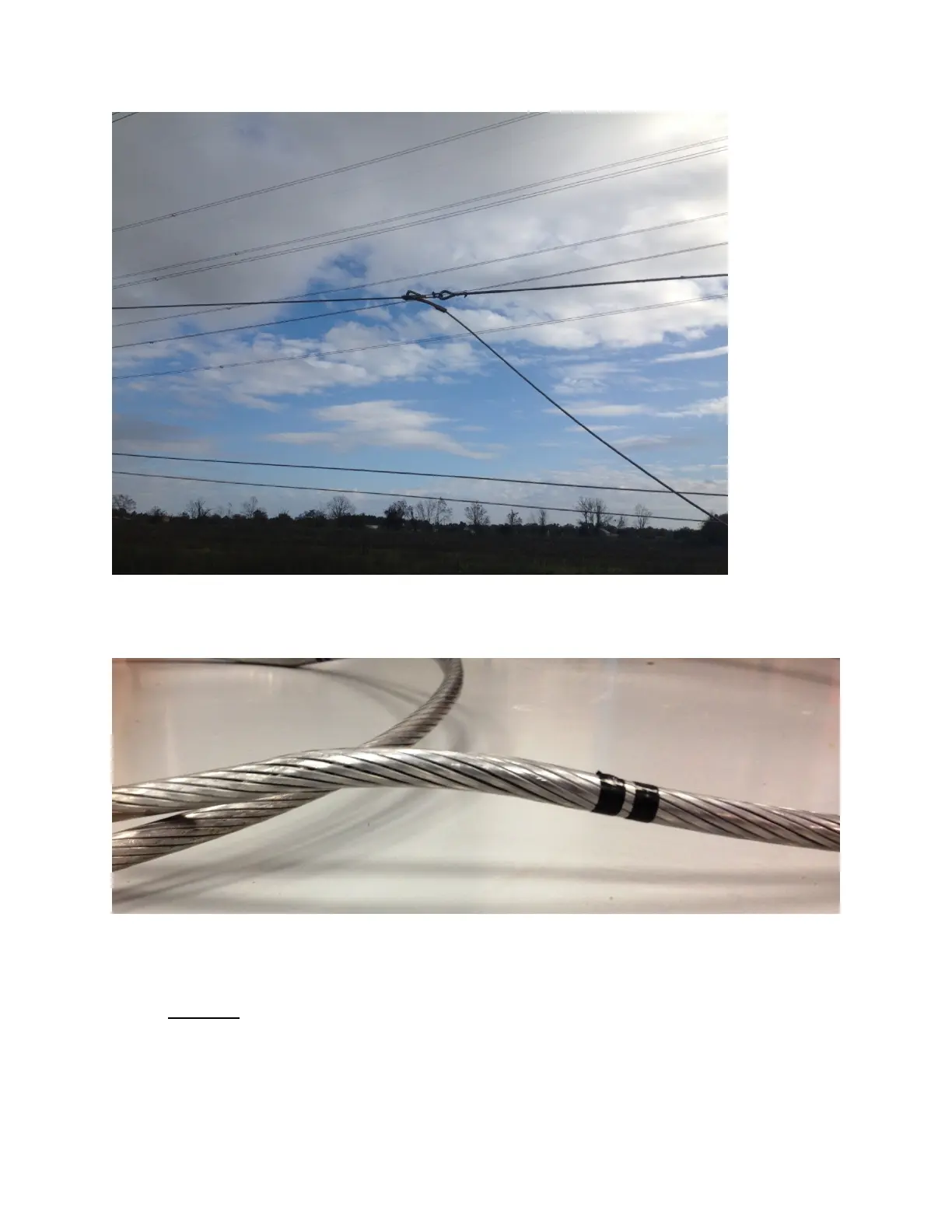

Figure 5: Care should be taken to ensure grips do not bend the conductor. Notice, the tail from

the grip is trained at a gentle angle, and tension on the slack side is low to prevent excessive

bending.

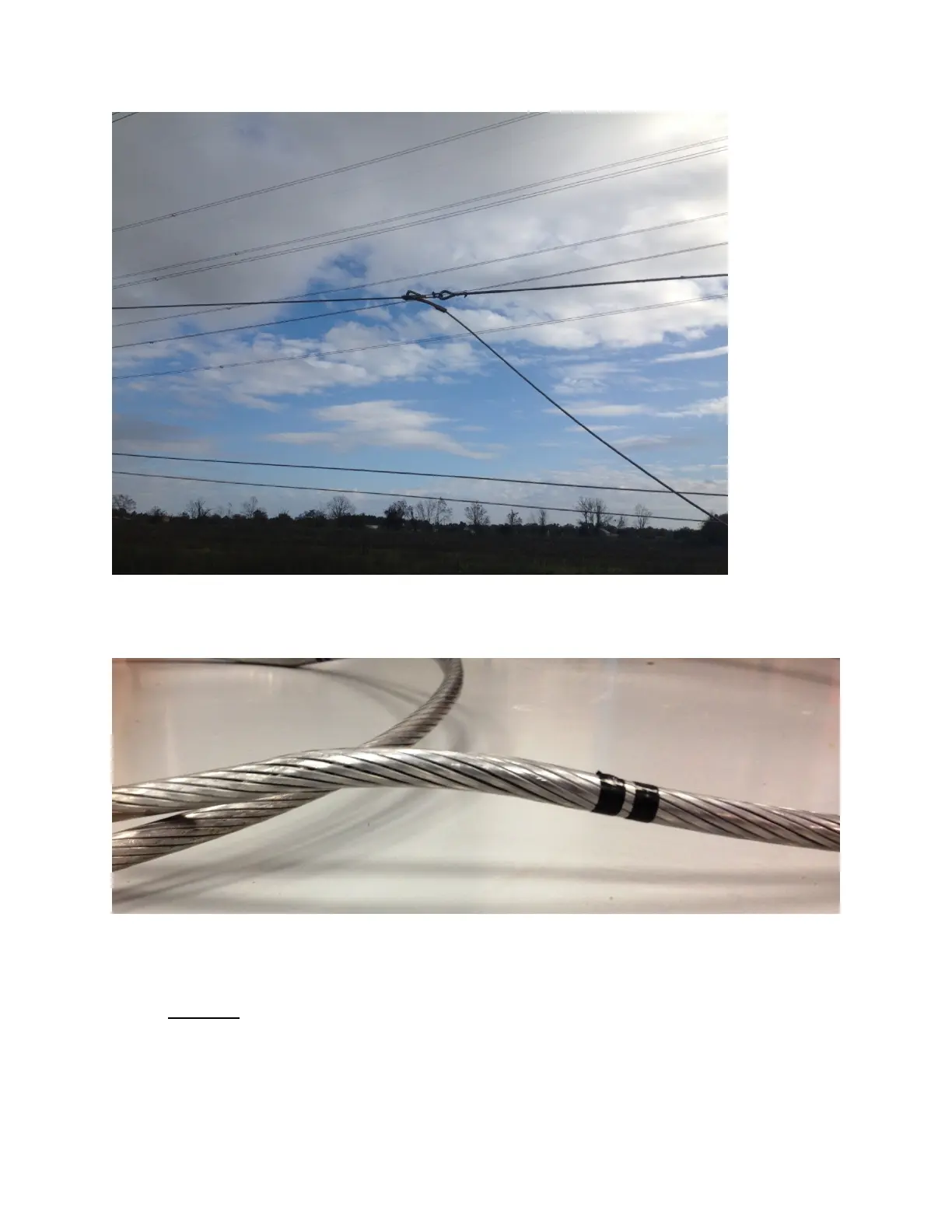

Figure 6: If the conductor has taken a “set” from bending, the bent section should be cut out

and a full tension splice installed. The section shown was bent 90° around a six (6) inch radius.

The tensile test showed a 25% strength reduction.

2) Crushing: steel strands are hard and can resist crushing loads. The resins used in C

7

conductor are among the toughest available. They can tolerate some abuse, but the

resin is softer than hard aluminum strands and if the conductor is crushed, the core can

sustain damage. Driving a vehicle across a conductor is an example of abuse that a steel

core conductor might survive but will damage a composite core. Similar to the case for

Loading...

Loading...