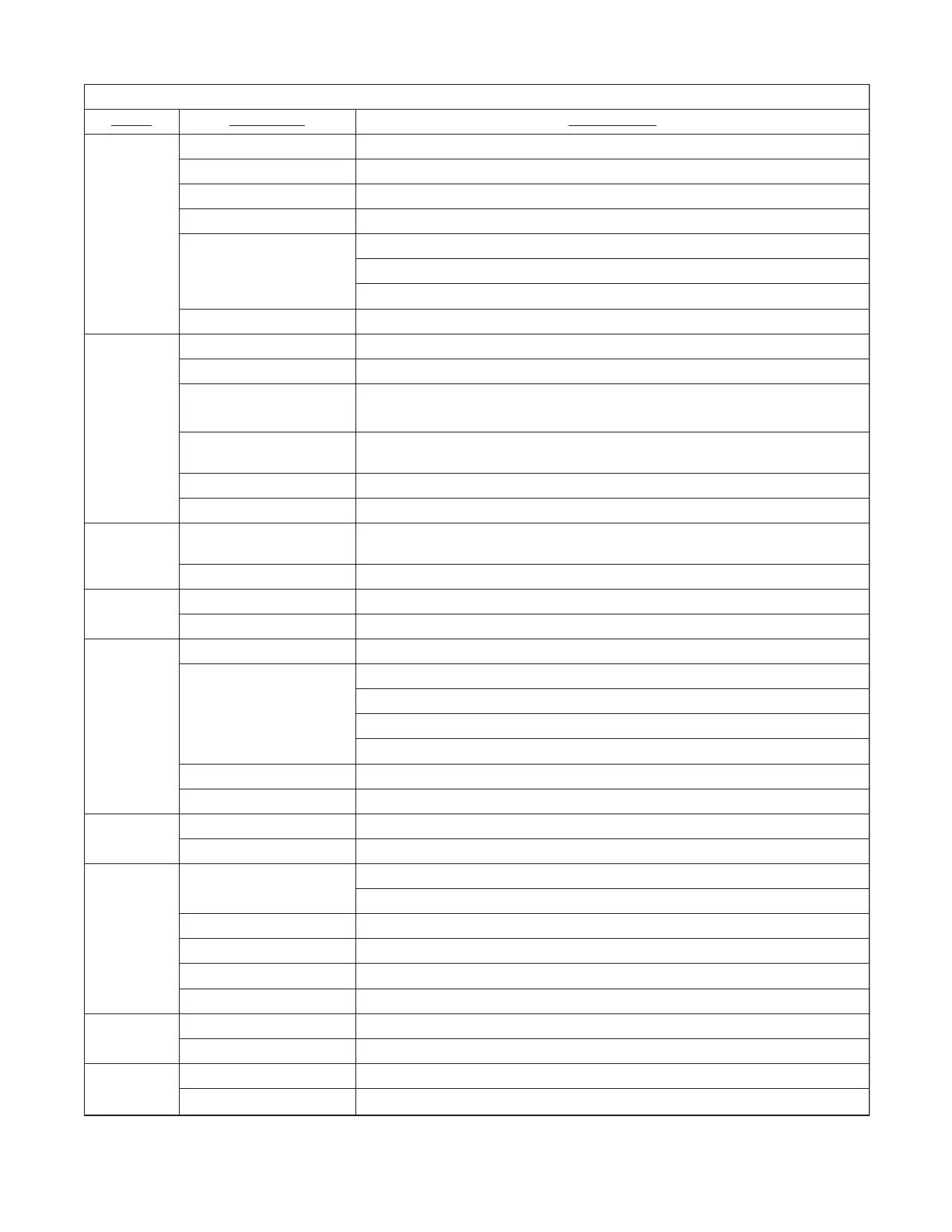

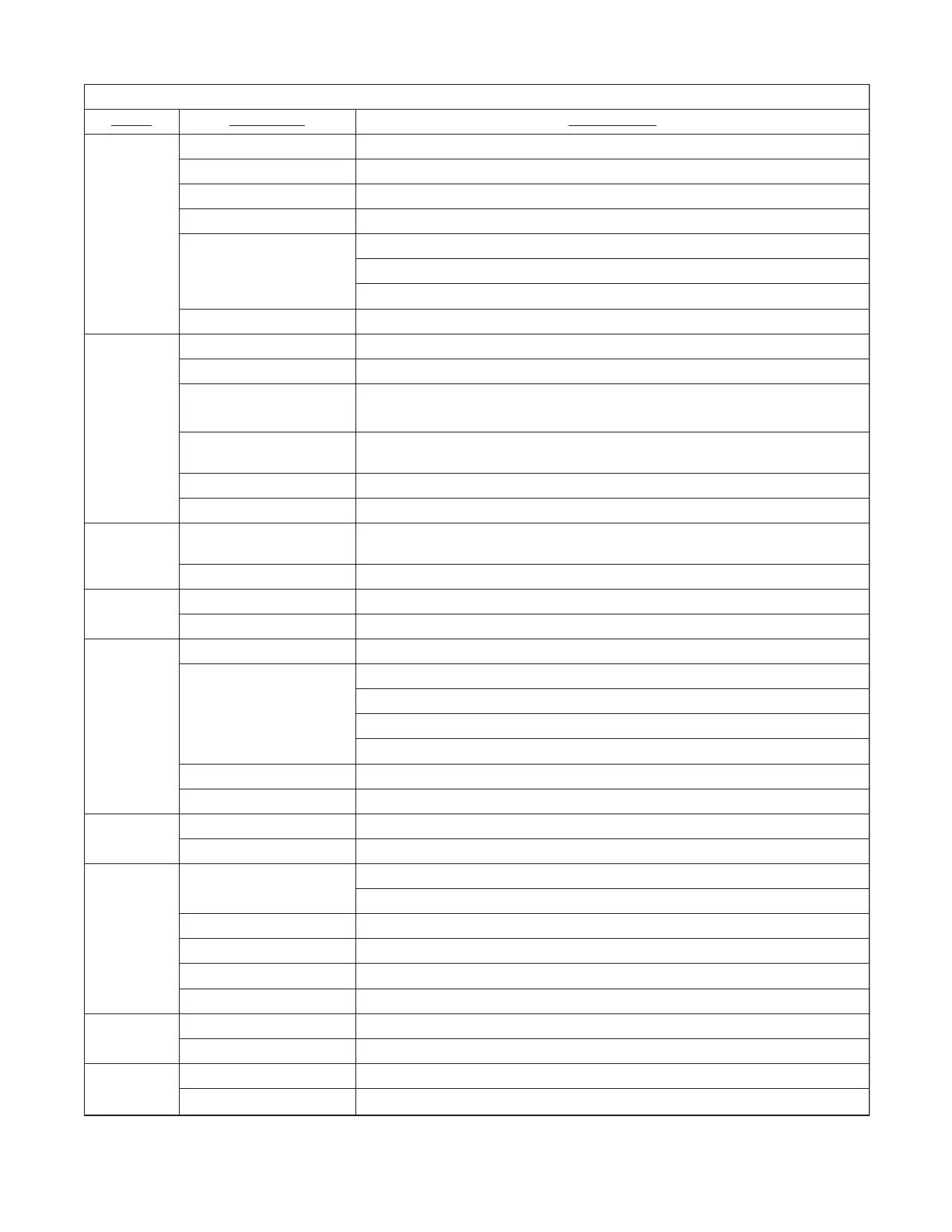

41

Project Complaints/Conditions*

Problem Possible Cause Corrective Actions

Poor Cooling

Refrigerant Leak

Check for refrigerant leaks in all refrigerant components. Repair leaks (as needed) per standard refrigera-

tion practices

Improper charge

Check for proper refrigerant charge. Charge to proper subcooling according to condenser manufacturers

instructions

Evaporator coil dirty Check for a dirty evaporator coil. Clean evaporator coil using only evaporator approved cleaning solutions

Return air filter is dirty If the return air filter is dirty. Inspect, clean or replace as needed

Low airflow

Inspect ductwork for damage or leakage of airflow. Repair as needed

Adjust fan speed (per this manual) for each outlet to achieve a minimum of 33 cfm/outlet

Add more outlets if required (minimum of 7/ton)

Improperly sized equipment.

Verify required Btu's by performing a heat loss calculation for the space. Compare to the equipment in-

stalled.

Blower Will

Not Run

No call from thermostat at board See "No Thermostat Call Displayed on Board" flowchart for troubleshooting steps

Coil not at temps

The blower will not start unless the proper coil temp for the thermostat call (heating or cooling) See "Coil

not at proper temps" flowchart for more troubleshooting steps

Verify proper voltage

Using the wiring diagram in this manual, identify the line voltage terminals going to the blower. Using a cali-

brated voltmeter, verify proper voltage to blower. 240v is standard, if unit has been converted for 115v then

115v should be applied to the blower. See "Improper voltage" flowchart for more troubleshooting steps

Static Pressure Hose may be

kinked

From the main screen on the display, press the "up" or "down" keys to find "S.P" reading. If blower is not

running and the screen is displaying a measure reading, then hose is kinked. Trace hose to locate the

kink and repair. If hose is not kinked, replace control board

Unit not commissioned properly Using the menu tree in this manual, verify the unit has been commissioned properly for the application.

Unit speed or static pressue set

point set incorrectly

Using the menu tree in this manual, verify that the blower is set to the proper speed or SP set point for

the appropriate thermostat input. Y1, G, Y2 etc…

Control Board not

powered

Improper Voltage

Ensure all wiring is proper per wiring diagrams. The board requires 24v from transformer to power up.

Repair as needed. See flowcharts "No thermostat call" and "Improper voltage" in this manual for more

troubleshooting steps.

Faulty Control Board If wiring has been confirmed to be good, no loose connections, then replace control board.

Auxilliary terminal

not closing

Improper commissioning

Using the menu tree in this manual, verify the auxilliary terminals have been commissioned to close per

the desired thermostat call.

Faulty Control Board

If board is properly commissioned, and LED light for auxilliary terminal is illuminated, then replace control

board.

Coil is freezing

No airflow See "Blower will not run" above.

Low airflow

Measure delivered airflow to the space and compare against "Required CFM's" table in this manual. If

low, adjust accordingly

Dirty air filter. Clean/replace as needed

Dirty evaporator coil. Clean as required

Inspect ductwork for damage or leakage of airflow. Repair as needed

Refrigerant Leak

Check for refrigerant leaks in all refrigerant components. Repair leaks (as needed) per standard refrigera-

tion practices

Improper charge

Check for proper refrigerant charge (with proper airflow established). Charge to proper subcooling ac-

cording to condenser manufacturers instructions

Sweating at

Supply Outlet

Air Leak at Supply Air Plenum Check taped joint at adapter. Tape joint properly if necessary.

Insulation at Outlet not Installed Check for insulation at the outlet. Make repairs if necessary.

Excessive Noise

at Terminator

High Supply Air Plenum Static

Pressure

Check static pressure and compare to the table provided in this manual. Check for and add flow restric-

tors as necessary in supply runs.

Check static pressure and compare to the table provided in this manual. If necessary, add additional outlets.

Sound Attenuating Tube not

Installed

Check for installation of sound attenuating tube. Where necessary, install sound attenuating tube.

Tight Radius in Sound Attenuating

Tube or in Supply Tubing

Check all tubig for tight radius. Where necessary, correct radius.

Incorrect Supply Tubing Length

Check that all supply tubing runs are 9ft minimum (including the 3ft sound atten. tube). Where necessary,

correct supply tubing length.

Improperly Balanced System Check that correct size orfices have been installed. If not, properly orfice supply tubing runs.

Excessive Noise

at Return Air Grill

Return Air Duct Not Installed

Properly

Check for minimum 90° bend in return air duct. If minimum requirement not met, correct the bend in the

return air duct to the 90° minimum.

Dirty Return Air Filter Remove and inspect the return air filter. Clean or replace filter as needed.

Excessive

Vibration

Foreign Matter in Blower Wheel Check for loose or damaged blower wheel. Replace Blower Assembly of necessary.

Blower Wheel Damaged or

Unbalanced

Remove and Inspect Blower Assembly. Remove and foreight matter and retest fan vibration.

* The table above explains the most common symptoms and solutions for SpacePak troubleshooting. Please reach out to technicalservice@spacepak.com if the

problem is not resolved using this table.

Loading...

Loading...