Internally, the mechanism of a servo motor uses a potentiometer attached

to the rotating shaft to sense the position. It measures the width of the

incoming pulse, and applies current to the motor to turn the shaft

correspondingly.

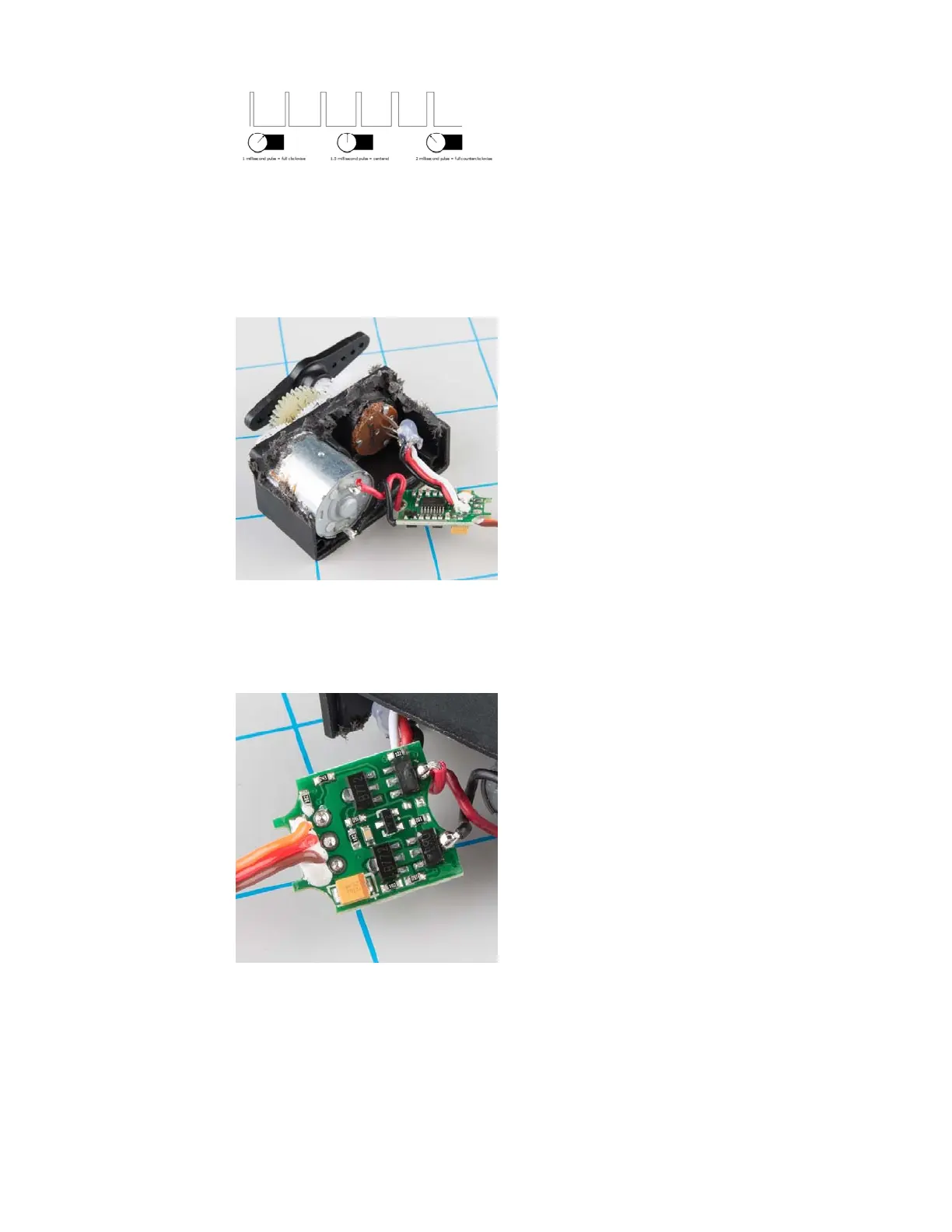

Here are the insides of a servo that’s been dissected. You can see the DC

motor, position potentiometer, and a small PCB. The PCB has a chip on

one side, possibly a small microcontroller.

Inside an RC servo

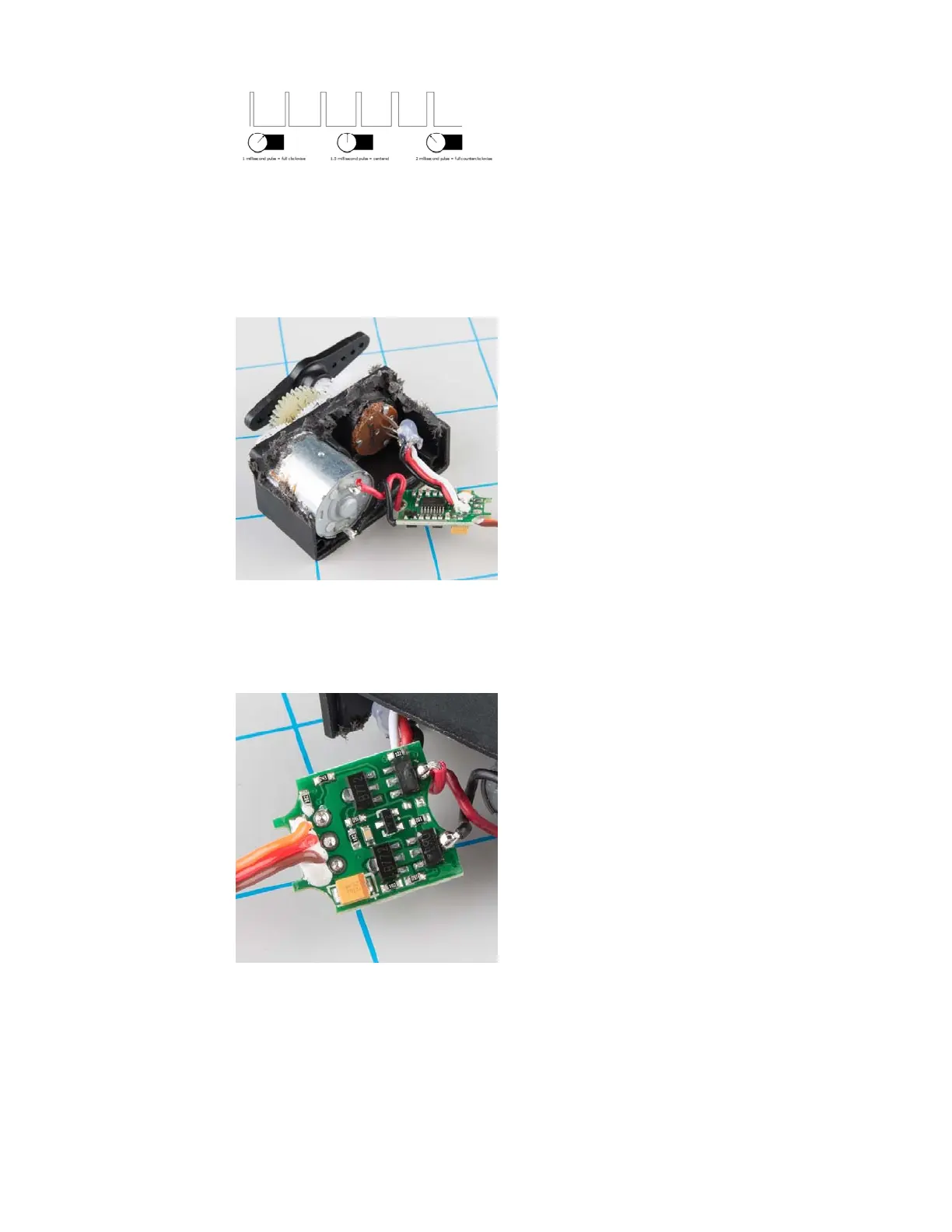

The other side of the PCB has some discrete transistors, probably in an

H-bridge configuration, which allow the controller to steer current through

the motor in either direction, for both clockwise and counterclockwise

rotation.

Back of the PCB

One Other Useful Servo

Ordinary RC servos turn over a 90° range – it’s useful for turning a steering

linkage, or adjusting the control surfaces on an airplane, but not so useful

as a drive mechanism. That’s where full or continuous rotation servos

come in.

Page 4 of 1

Loading...

Loading...