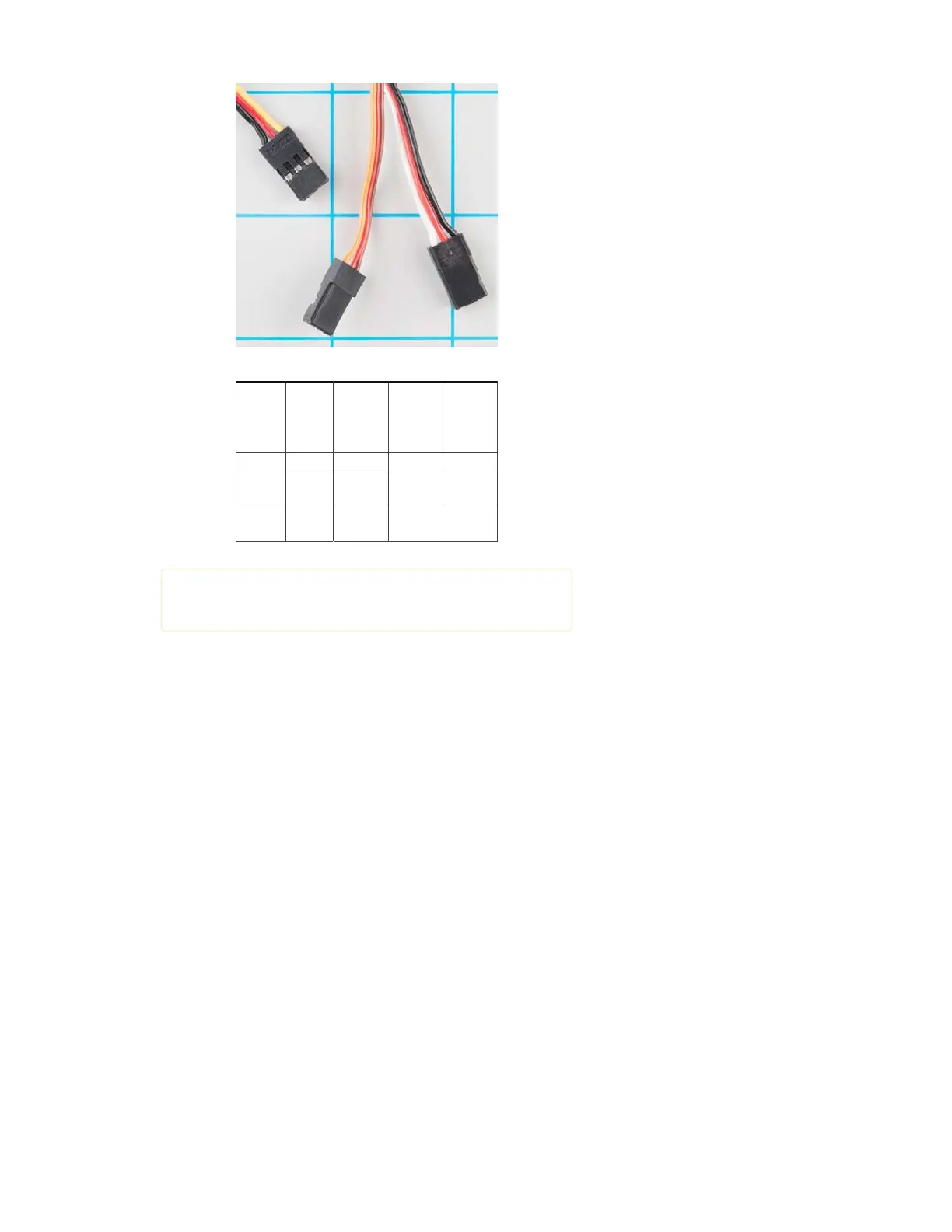

The table below summarizes common color schemes.

Pin

Number

Signal

Name

Color

Scheme

1

(Futaba)

Color

Scheme

2

(JR)

Color

Scheme

3

(Hitec)

1 Ground Black Brown Black

2

Power

Supply

Red Red

Red or

Brown

3

Control

Signal

White Orange

Yellow or

White

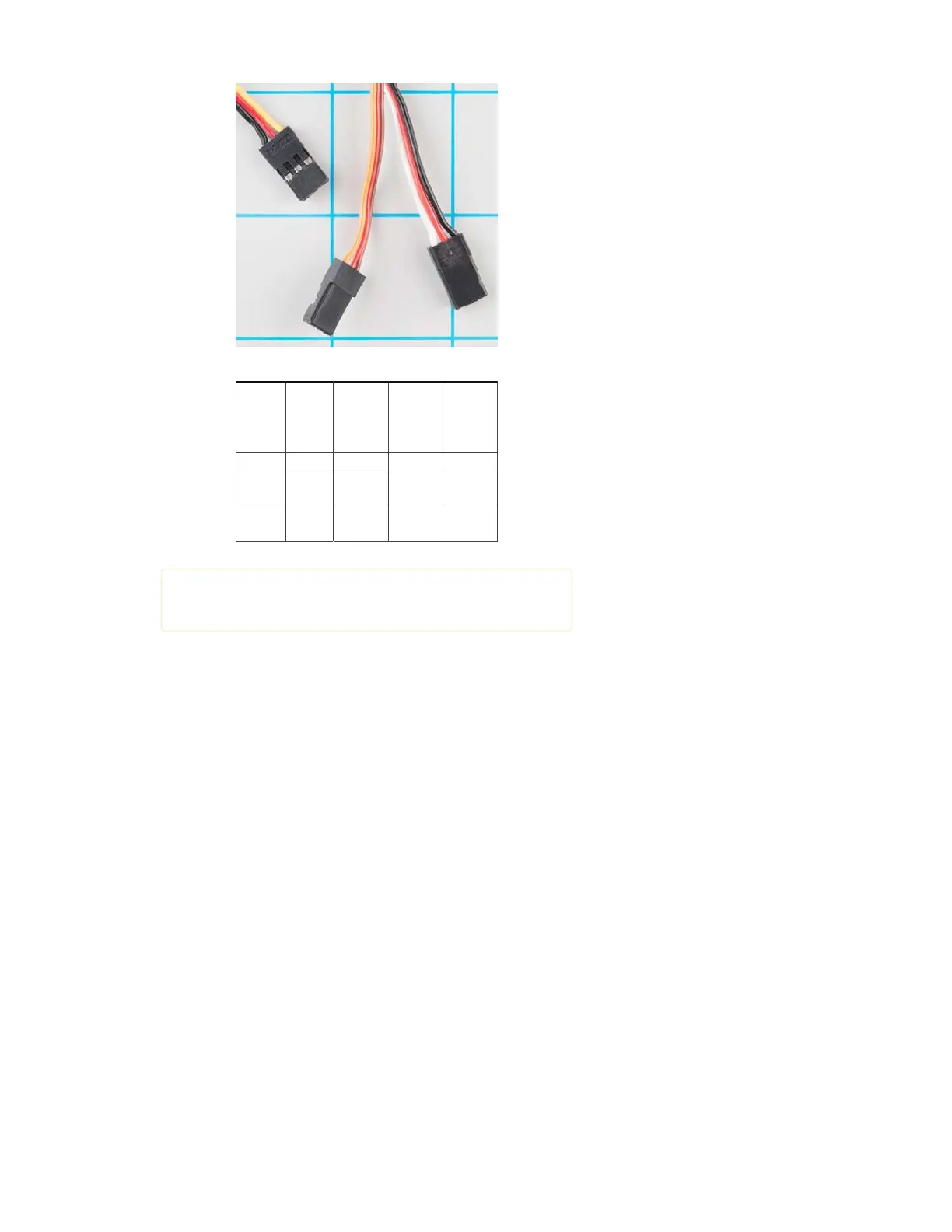

Servo connection Color Coding

Heads up! If you’re in doubt about your color scheme, check the

documentation – don’t plug it in backwards!

Powering Servos

In RC vehicles, 5.5V is the nominal battery voltage. It will be somewhat

higher after a charge, and it will droop as the batteries discharge. As the

voltage drops, the available torque also drops – if you’ve driven RC

vehicles, you’re no doubt familiar with the loss of control that occurs as the

batteries get weaker. It starts to feel sluggish just before it dies.

If you’re not using batteries, the 5VDC available from a garden variety

power supply is a good option. If you’re using the Servo Trigger to control

your motor, the absolute maximum supply voltage that should be applied

is 5.5 VDC.

Regardless of how you’re powering them, it’s worth noting that the current

consumed by the motor increases as the mechanical loading increases. A

small servo with nothing attached to the shaft might draw 10 mA, while a

large one turning a heavy lever might draw an Ampere or more!

Control signal

Servos are controlled with a specific type of pulse train signal. The pulses

occur at a 20 mSec (50 Hz) interval, and vary between 1 and 2 mSec in

width. The Pulse Width Modulation hardware available on a microcontroller

is a great way to generate servo control signals.

Common servos rotate over a range of 90° as the pulses vary between 1

and 2 mSec – they should be at the center of their mechanical range when

the pulse is 1.5 mSec.

Page 3 of 1

Loading...

Loading...