Spearhead Multicut 620

24

2424

24

Service & Maintenance

Service & MaintenanceService & Maintenance

Service & Maintenance – Every 8 hours

Every 8 hours

Every 8 hoursEvery 8 hours

Every 8 hours

• Dismantle and clean the main input P.T.O shafts sliding surfaces and re-

grease; failure to do this will result in serious damage to the splitter gearbox.

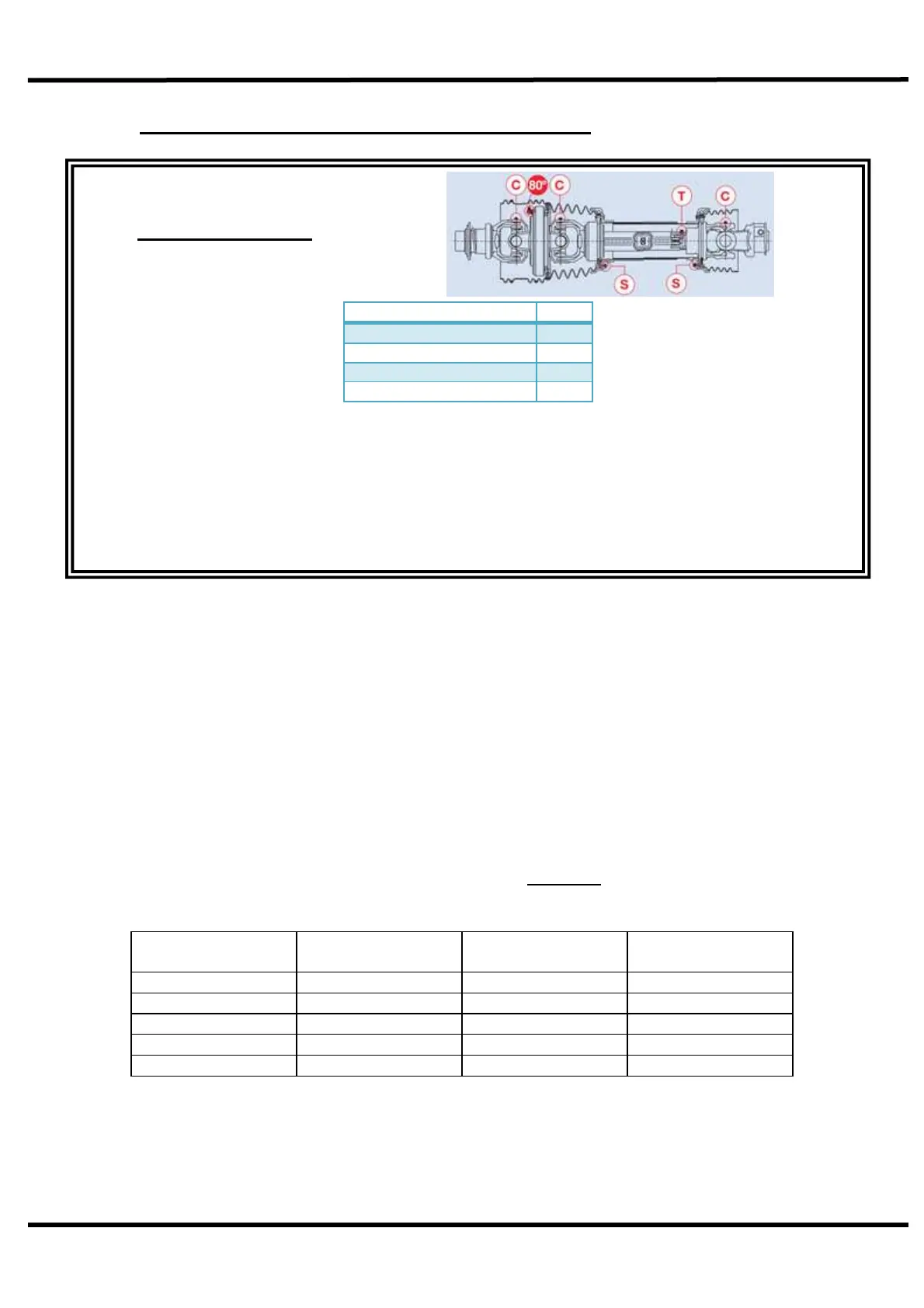

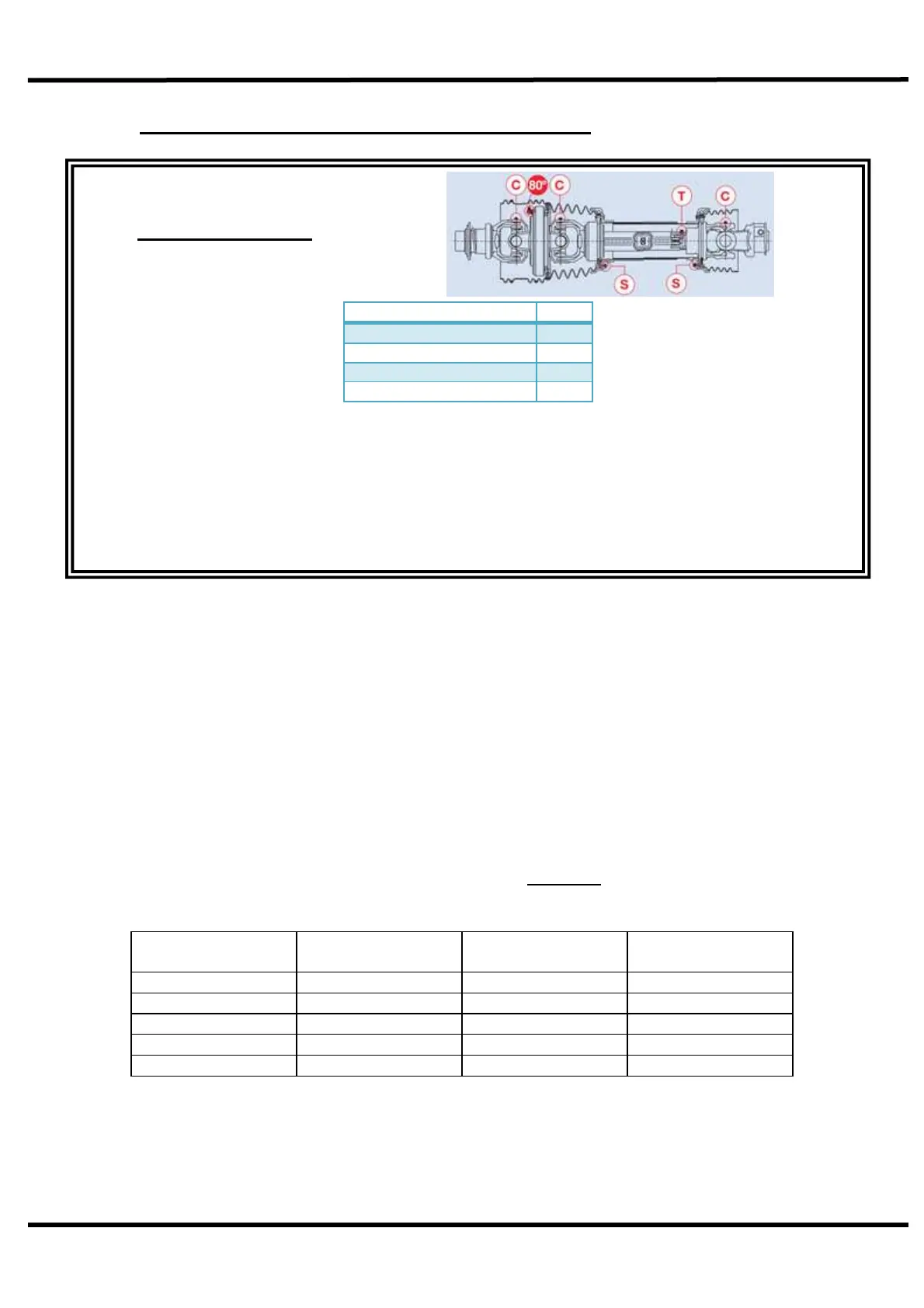

• Grease all universal joints, (Fig. 10) paying particular attention to the constant

velocity joint. If under-greased this constant velocity joint will soon fail.

• Grease the wing drive shaft tubes, (note the hole in the plastic tubing for

access).

• Lubricate the retaining collar on all the drive shaft guards (Fig. 10).

• Grease PTO inner tube and push pins (Fig. 10).

•

Check all bolts are tightened to the correct Torque (Fig.11).

Torque Settings

Torque SettingsTorque Settings

Torque Settings

The Torque figures given below are recommended maximum settings only.

Size: Tensile strength: Description: Torque setting:

Nm.

M16 8.8 Gearbox bolts 280

M16 8.8 Axle clamps 280

M24 8.8 Blade bolts 540-800

M24 12.9 Axle bolts 1500

Wheel nuts 270

Cross

22 g

Shield Bearings

6 g

Telescopic Members

32 g

80° CV-joint

80 g

• For maximum life and performance, the CV body must be greased regularly. Lubricate with

the driveline in a straight position - up to 30 pumps of grease may be required.

• The metal drive tubes must be greased to operate properly.

• Shielding is subject to damage from abuse and weathering. Replace all damaged

components and all shielding removed during maintenance.

•

Do not use PTO adapters with CV drivelines. Replace special taper pin bolts only with

genuine OEM parts, periodically c

Primary input shaft.

Loading...

Loading...