Spearhead Multicut 620

26

2626

26

Clutch

Clutch Clutch

Clutch Maintenance

MaintenanceMaintenance

Maintenance

& Settings

& Settings& Settings

& Settings

BONDIOLI Manufacture (Belleville Spring)

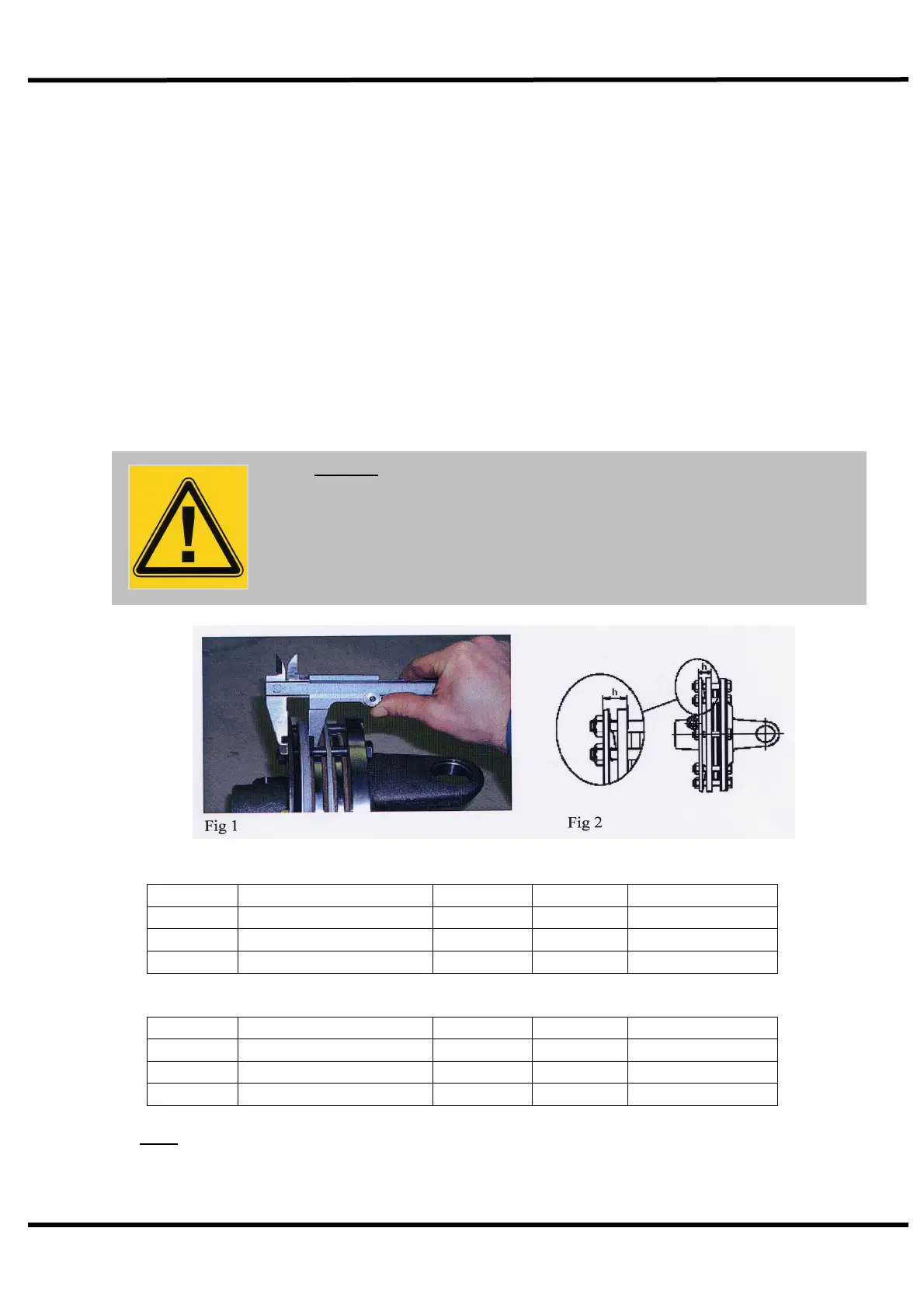

Check the condition of the friction discs before use and following periods of storage.

Release the tension from the spring, turn the clutch while holding the P.T.O

stationary. Adjust the spring compression to the original setting.

Following seasonal use, unload the spring tension and store clutch assembly in a dry

place. Check condition of friction linings and reset spring compression to original

height before use.

Should the assembly overheat due to frequent or prolonged clutch slipping, dismantle

for inspection. The original thickness of the lining is 3.2mm, replace them when worn

to 2.5mm. Clean up all contact surfaces and replace any damaged components

before assembly.

BONDIOLI

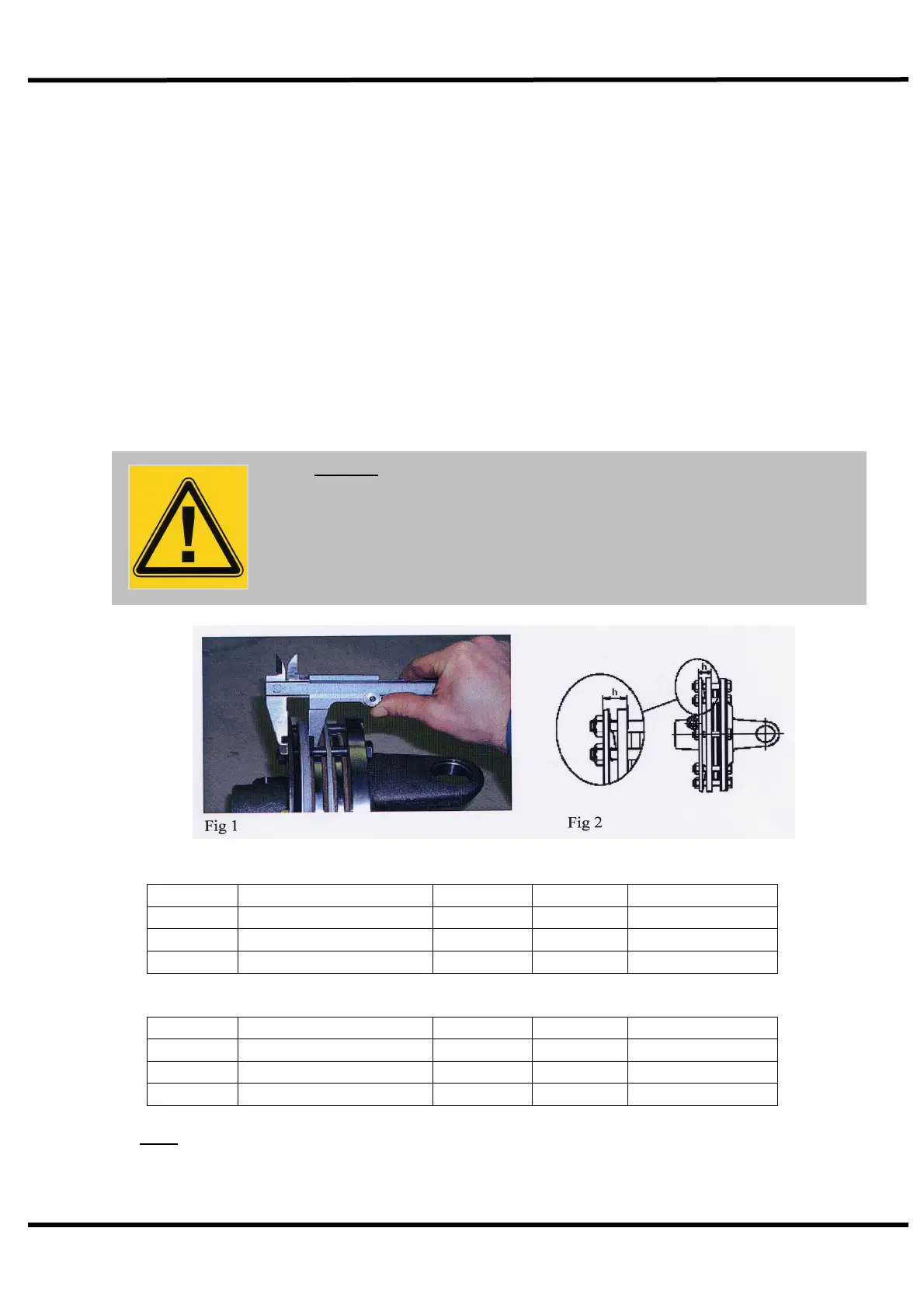

Standard - 3 Blade Per Rotor

2 Centre (2 plate) 5770223 18.9mm 620 (1000rpm)

2 Inner Wing (4 plate) 5770215 17.6mm 620 (1000rpm)

2 Outer Wing (2 plate) 5770207 17.8mm 620 (1000rpm)

Optional - 6 Blade Per Rotor

2 Centre (2 plate) 5770223 18.5mm 620 (1000rpm)

2 Inner Wing (4 plate) 5770215 17mm 620 (1000rpm)

2 Outer Wing (2 plate) 5770207 17.2mm 620 (1000rpm)

Note

The dimensional setting ‘h’ applies to later type clutches where the 2 discs being

measured are of equal diameter.

Warning

The slip clutch is there to protect the gearbox. If the

blades strike a large obstacle they may get damaged or

break - avoid these conditions.

Loading...

Loading...