Spearhead QHD Flail Mowers

16

Blunt flails leave an untidy finish and absorb excessive power, when re-

sharpening always wear protective clothing and goggles.

When flails are showing severe wear, damage or cracking, they must be

replaced immediately. Never attempt to weld the flails, as this will make them

very brittle, thus extremely dangerous. Do not take risks with the cutting flails,

if in doubt replace.

When replacing flails always replace bolts and nuts for new.

Regularly check that all bearing bolts are tight.

It is imperative the screws are checked on the taper locks (once bedded in

loctite glue may prove useful).

Greasing

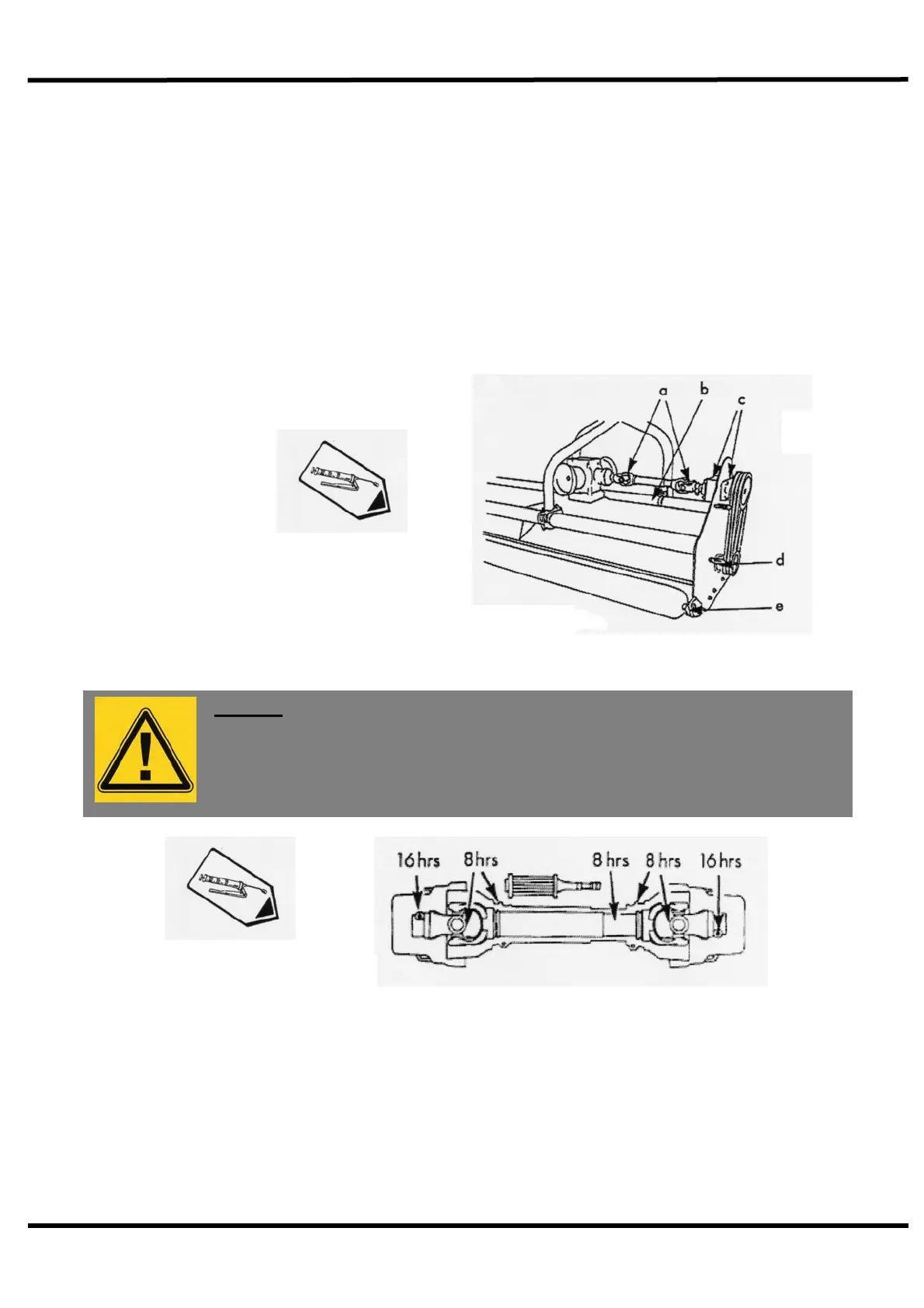

Daily grease all points shown below.

Fig. 6

Grease point for rotor, cross shaft and rear roller bearings.

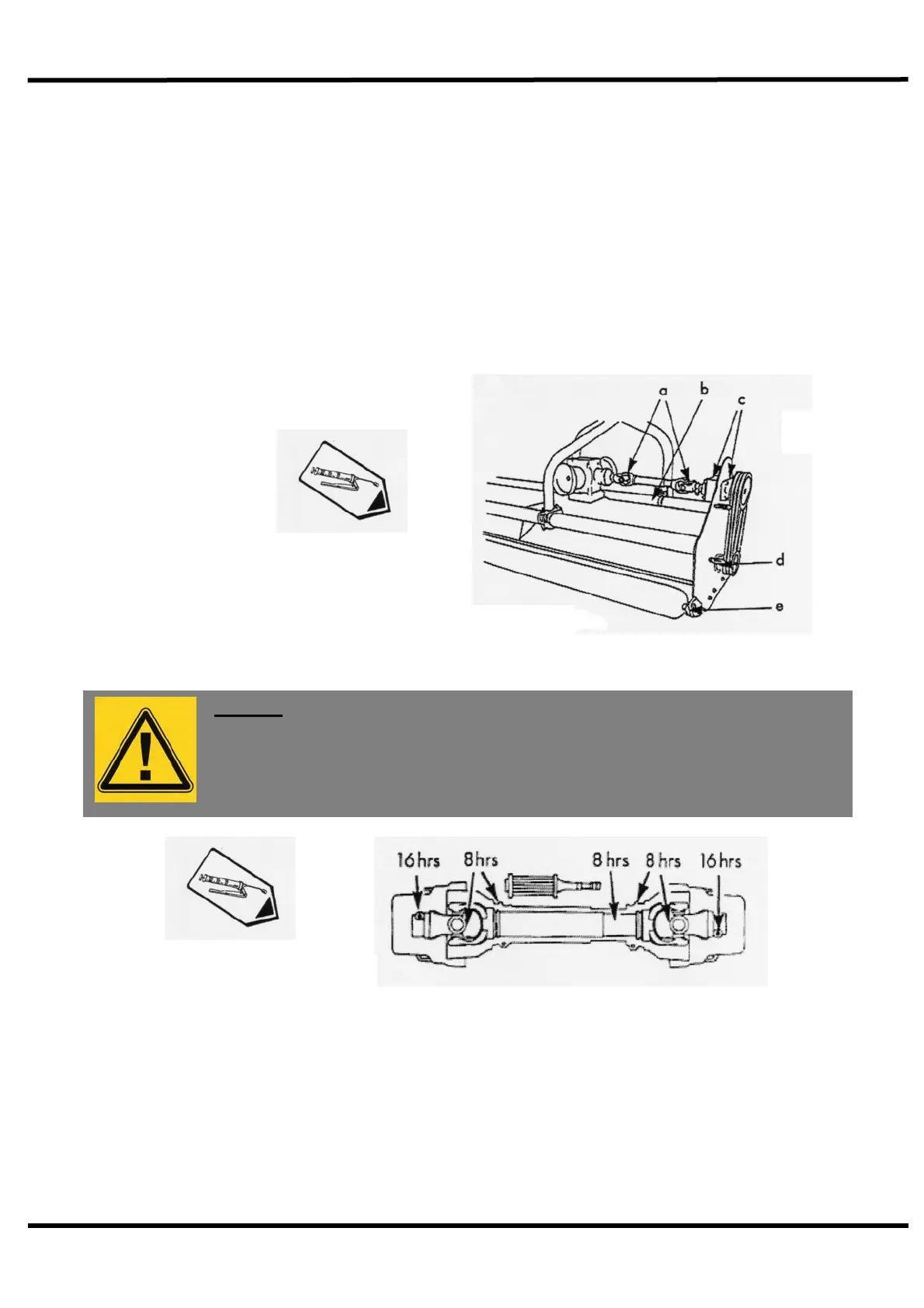

Warning

Grease rotor bearing and rear roller at least every 8 hours and especially

after washing.

Fig 6

Fig 7

Fig. 7

Dismantle and clean PTO sliding surfaces and re-grease universal joints.

Loading...

Loading...