Spearhead QHD Flail Mowers

19

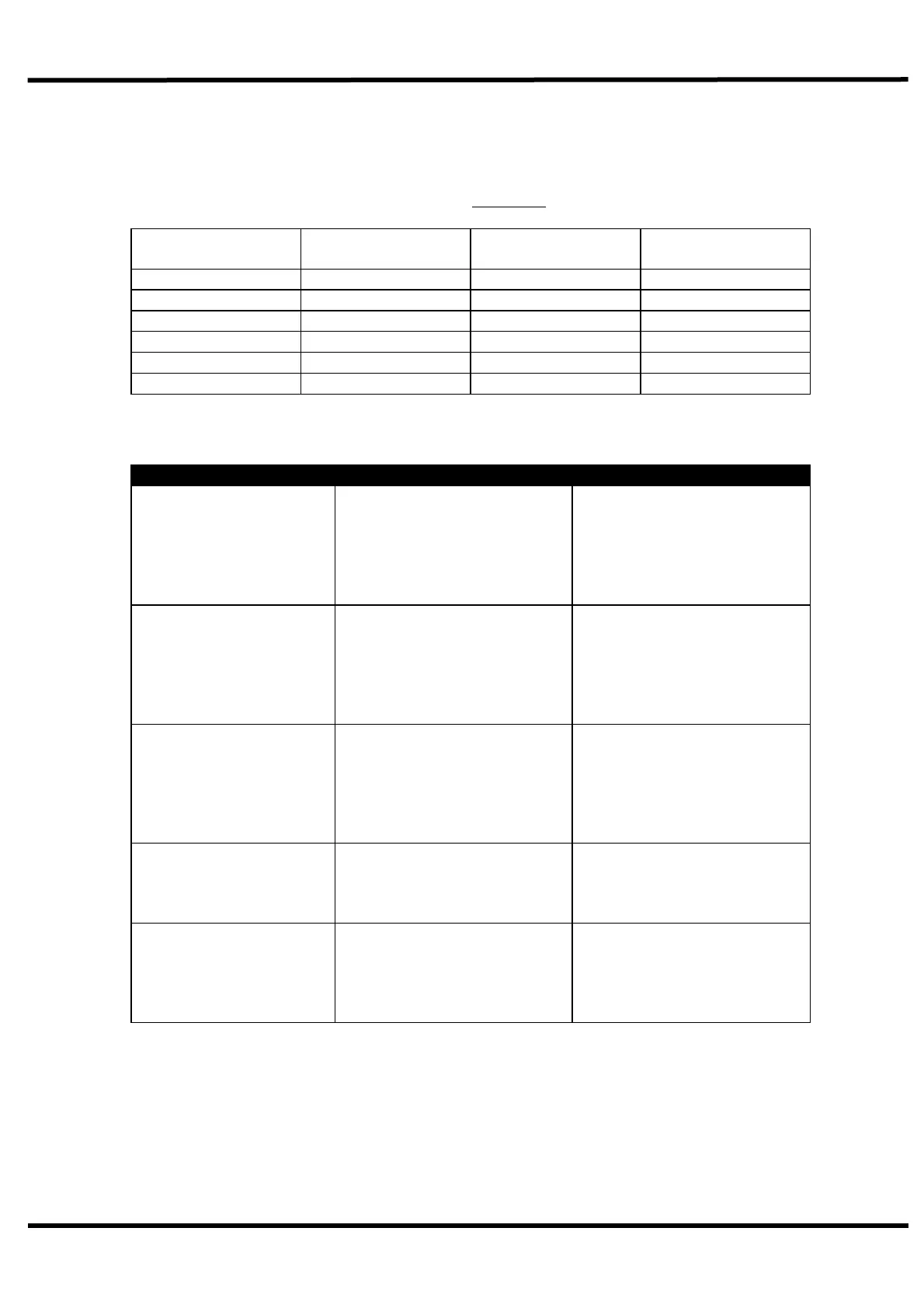

Torque Settings

The torque figures given are recommended maximum settings only

Size: Tensile strength: Description: Torque setting:

Nm.

M8 12.9 Pulley clamps 45

M10 8.8 General fasteners 65

M12 8.8 General fasteners 114

M16 8.8 Roller plate bolts 280

M14 10.9 Flail bolts 200

M24 8.8 Head stock bolts 950

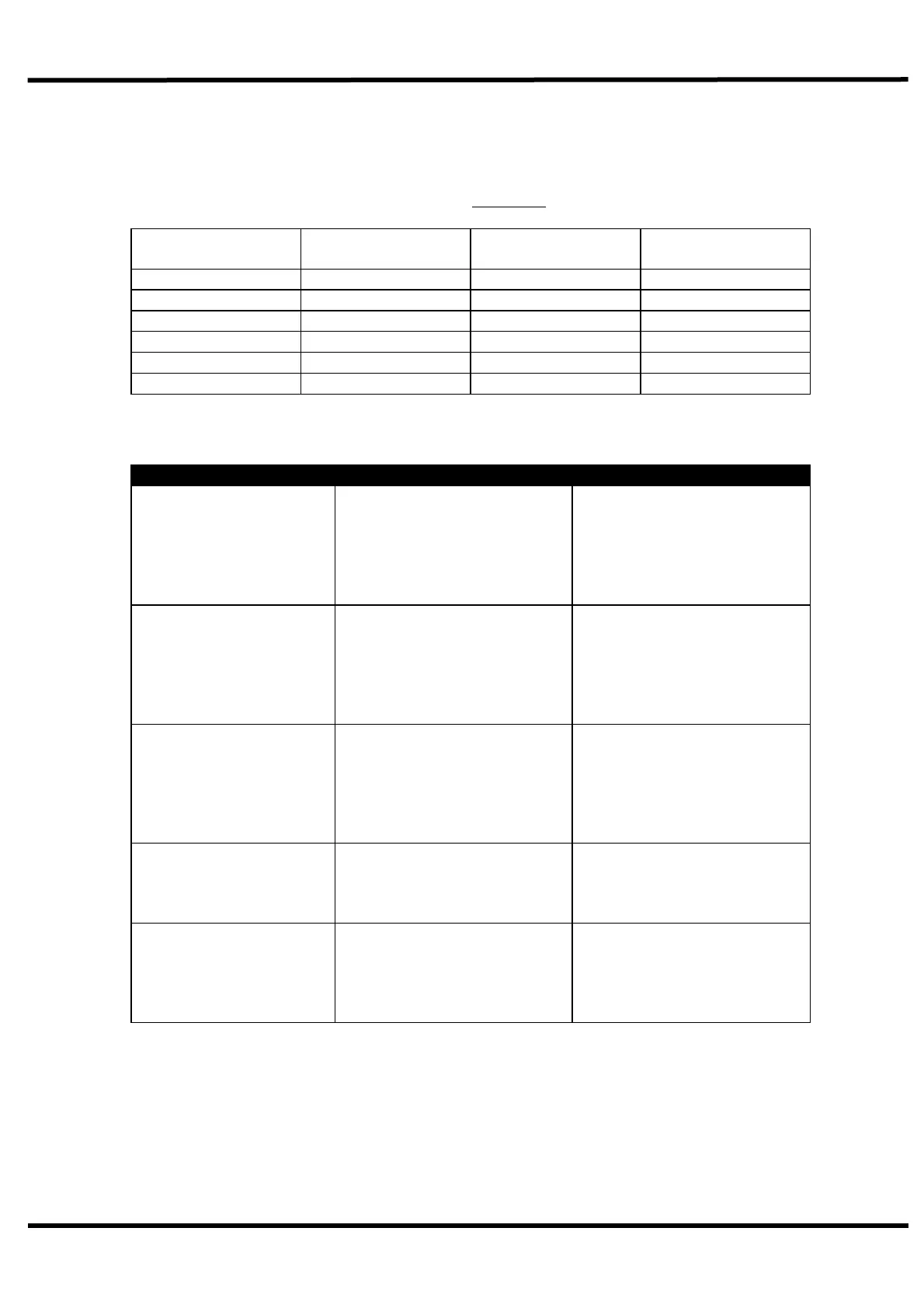

Troubleshooting

Problem Cause Solution

Gearbox Overheating

Oil level incorrect

Oil grade incorrect

Implement overloaded

Wrong P.T.O. speed

Check oil level

Check oil grade

Reduce forward speed

Ensure tractor P.T.O. speed

matches implement.

Excessive Belt Wear Belt and Pulley condition

Pulley Alignment

Incorrect belt tension

Overloading of implement

Replace if necessary

Check Alignment

Tension belts to spec.

Reduce forward speed or

increase height of cut.

P.T.O. wear UJ failure Working angle too great

Shaft incorrect length i.e.

Bottoming out

Lack of maintenance

Reduce offset of implement

Resize P.T.O. shaft as

recommended

Grease P.T.O. shaft as

recommended.

Cut quality Flails worn

Rotor speed/Direction

Crop condition.

Replace worn flails

Check tractor P.T.O. speed

Look for suitable conditions.

Rotor bearing failure Rotor out of balance

Wire/string in bearing

Lack of maintenance

Water in bearing.

See rotor vibration

Replace bearings

Re-balance/replace rotor

Remove debris.

Note:

When operating in arduous conditions with a tractor of more than 80HP, you

reduce the strain on the drive line by;

Running with 1000 speed set-up

Keeping the PTO shaft straight

Loading...

Loading...