Spearhead QHD Flail Mowers

2

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with Spearhead Machinery Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the Spearhead Machinery Limited web site at

www.spearheadmachinery.com, log onto ‘Dealer Inside’ and select the ‘Machine Registration button’

which can be found in the Service Section of the site. Confirm to the customer that the machine

has been registered in the section below.

Should you experience any problems registering a machine in this manner please contact the

Spearhead Service Department on 01789 491867.

Registration Verification

````````

……………………..…………………………………………………………….

Dealer Address: …….………………………………………………………………………….

Customer Name: ……………………..…………………………………………………………

Date of Warranty Registration: ……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section has been completed and signed by the selling dealer to

verify that your machine has been registered with Spearhead Machinery Limited.

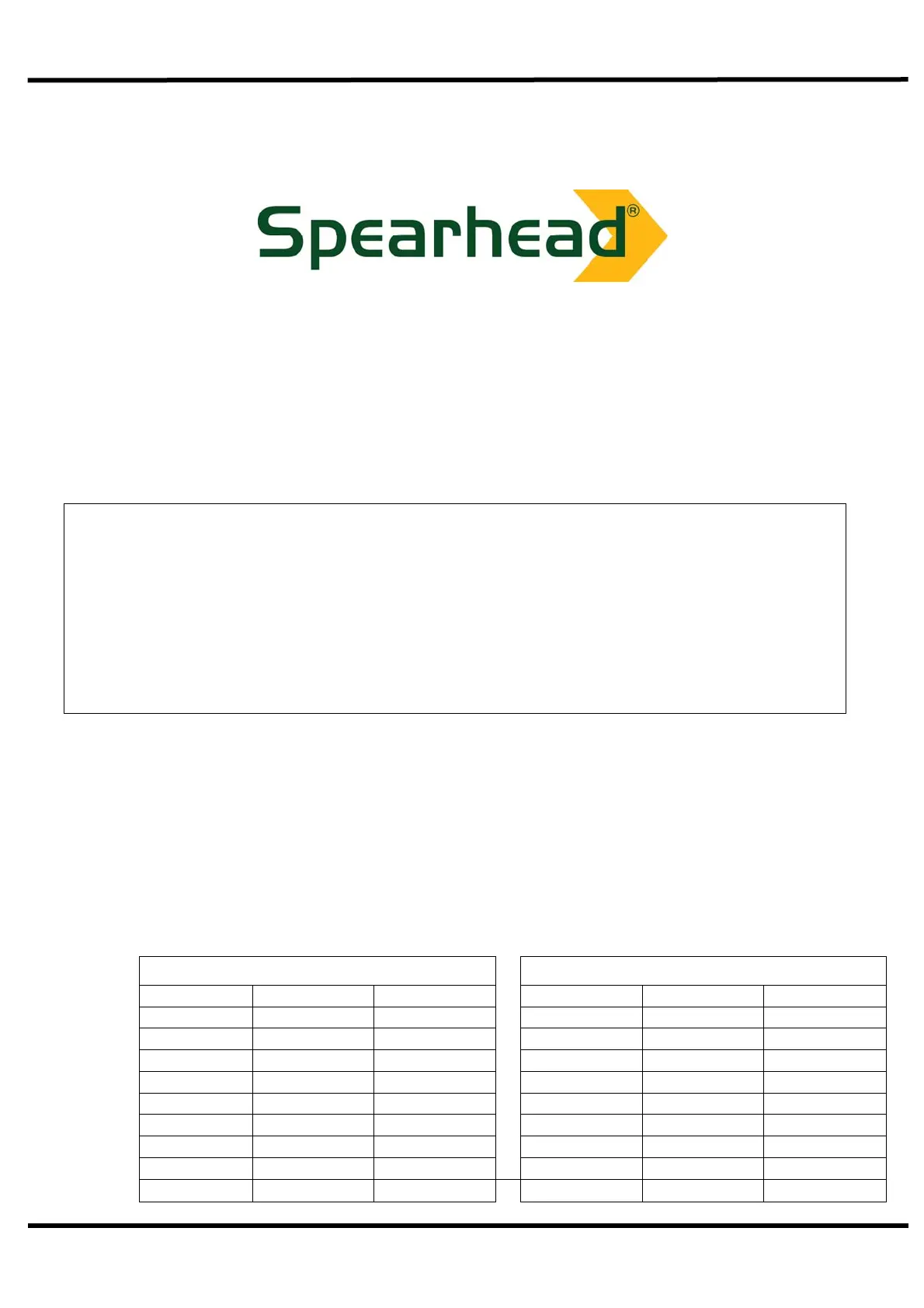

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s

responsibility to regularly inspect all nuts, bolts and hose connections for tightness and re-

tighten if required. New hydraulic connections occasionally weep small amounts of oil as the

seals and joints settle in – where this occurs it can be cured by re-tightening the connection –

refer to torque settings chart below. The tasks stated above should be performed on an hourly

basis during the first day of work and at least daily thereafter as part of the machines general

maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP Setting Metric

BSP Setting Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm 19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm 22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm 27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm 30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm 32 mm

1” 125 Nm 41 mm 1” 203 Nm 41 mm

1.1/4” 190 Nm 50 mm 1.1/4” 305 Nm 50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm 55 mm

2” 420 Nm 70 mm 2” 400 Nm 70 mm

Loading...

Loading...