19

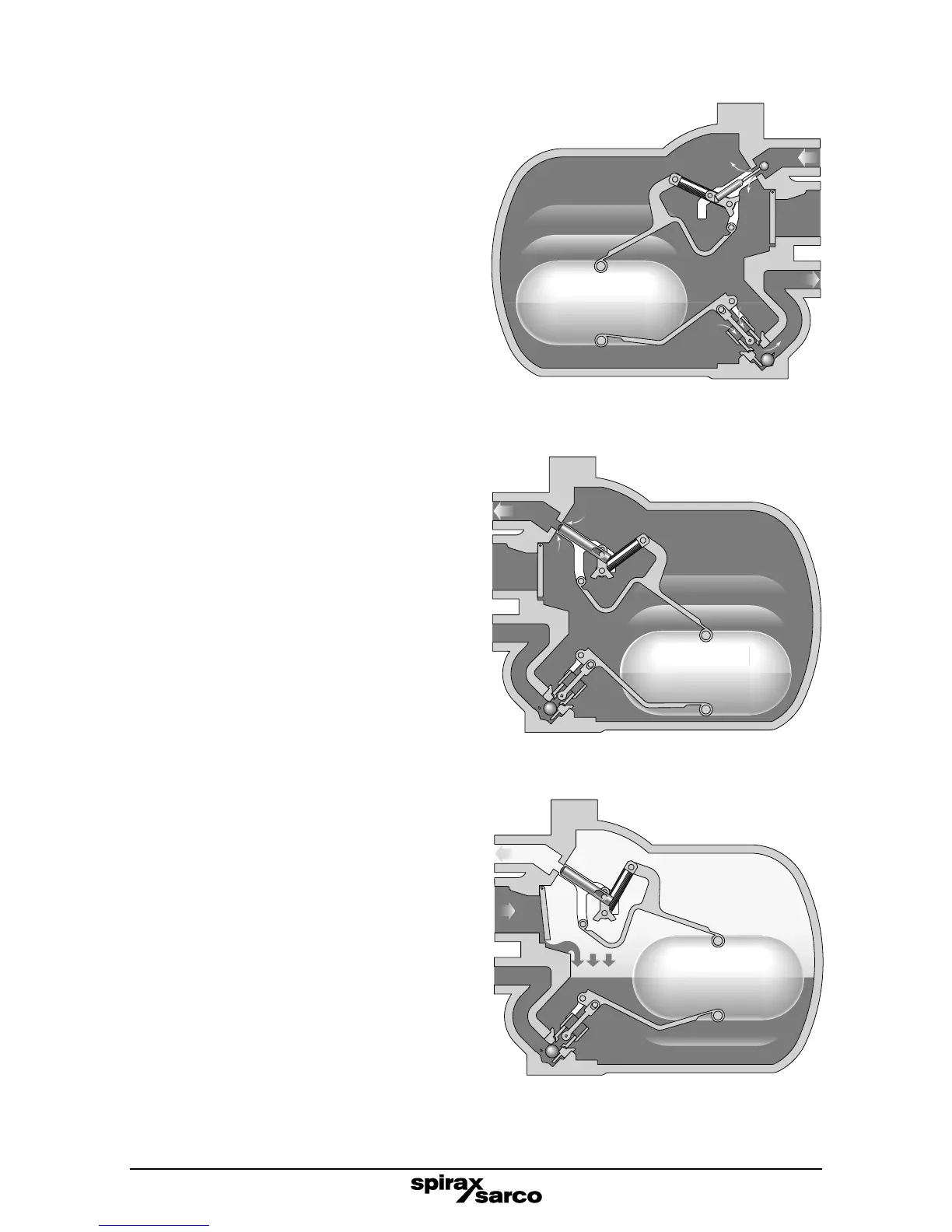

Step 4 (Figure 8)

The snap action mechanism ensures

a rapid change from the trapping

mode to the active pumping mode.

With the motive inlet valve open, the

pressure in the APT14, APT14HC

and APT14SHC increases above

the total backpressure and the

condensate is forced out through

the trap seat into the plant’s return

system.

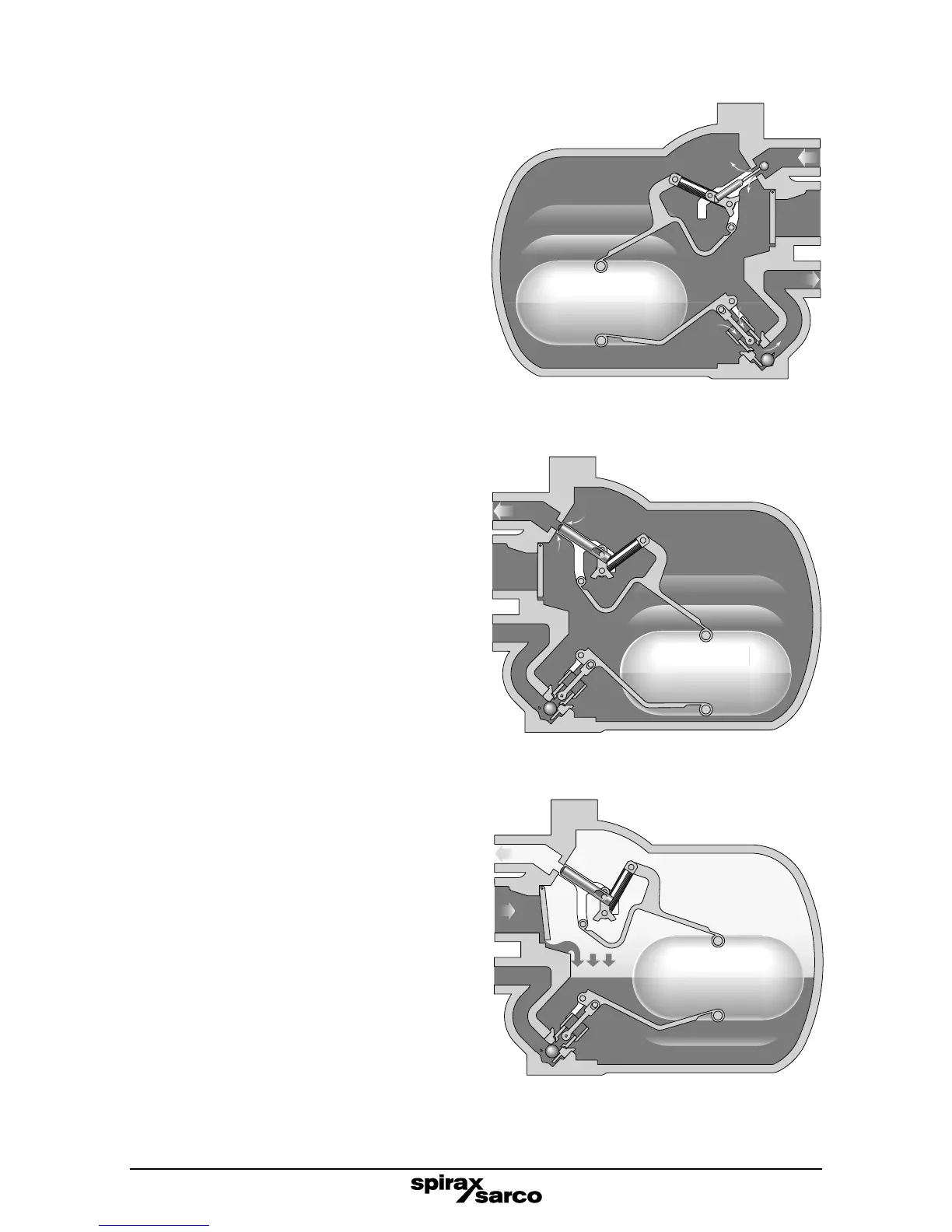

Step 5 (Figure 9)

As the condensate level falls

within the main chamber, the

float re-engages the change

over linkage, causing the motive

inlet to close and the exhaust

valve to open.

Step 6 (Figure 10)

As the pressure inside the APT14

equalises with the condensate inlet

pressure through the open exhaust

valve, condensate re-enters via

the inlet swing check valve. At the

same time the outlet ball check

valve (APT14 only) ensures no

condensate can drain back into the

main chamber and the trapping or

pumping cycle begins again.

Note: The APT14HC and

APT14SHC requires an external

Spirax Sarco DN40 disc check

valve to be fitted to the condensate

outlet, between the flanges.

Fig. 10 APT14 shown

Fig. 9 APT14 shown

Fig. 8 APT14 shown

Motive

steam

inlet

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Return to Step 1.

Loading...

Loading...