22

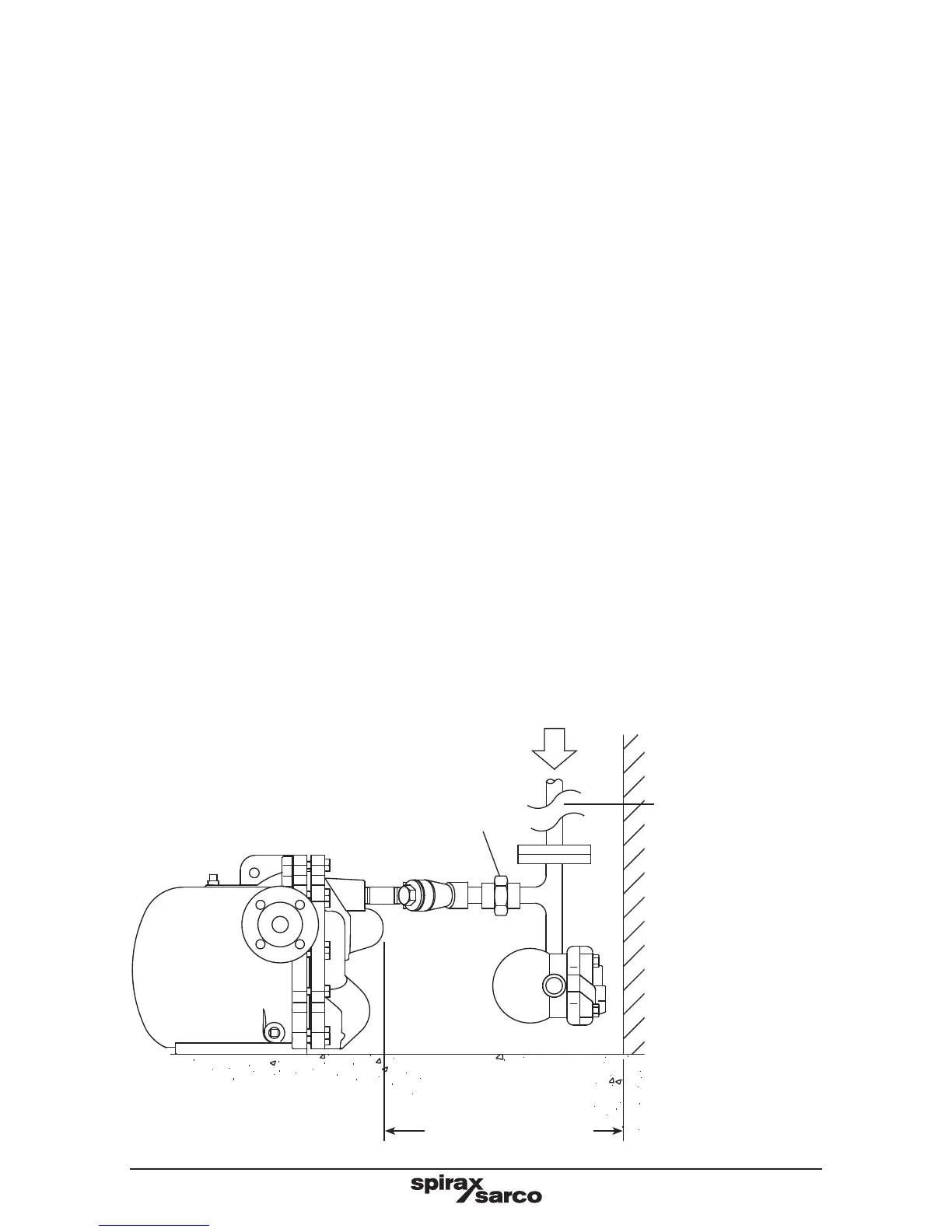

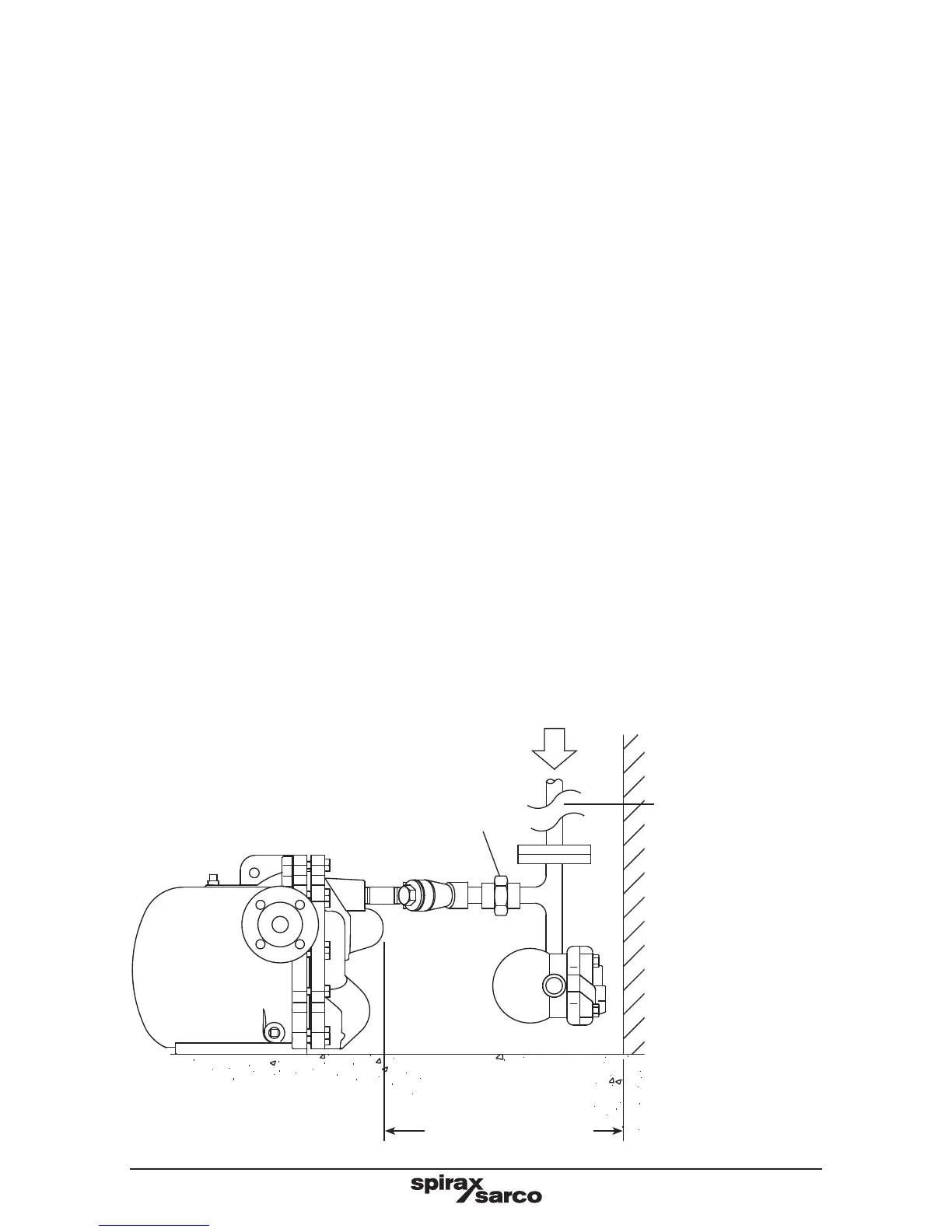

4.1 Inlet piping

To prevent condensate backing up into the equipment being drained, it is recommended that

the inlet pipework is sufficiently sized to accumulate condensate during the pump’s discharge

cycle. Generally a length and diameter of pipe to accommodate the following condensate

capacity will be sufficient: 4 litres (1.1 gallons) for an APT14 or 8 litres (1.76 gallons) for an

APT14HC and APT14SHC. It is recommended this condensate reservoir is situated at least

1 pipe diameter below the process outlet but as high as possible above the APT inlet (up to

1 metre (40")). It is essential that a Spirax Sarco Y-type strainer is fitted at the condensate

inlet of the APT14, APT14HC and APT14SHC, as shown in Figure 12.

4.2 Recommended installation head

An installation head of at least 0.3 m (12 ins) from the base of the unit is recommended.

Minimum 0.2 m (8") with reduced capacity; Maximum 1 m (40"). Note: During cold start-up

conditions, it is possible for hydraulic pulsing of the inlet check valve to occur. It is advisable

in this case to install a throttling isolation valve to reduce the filling pressure.

4.3 Connections (refer to the installation diagram, Figure 12)

The APT's have four connection ports. The DN40 (1½") - APT14 or DN50 (2") - APT14HC

and APT14SHC port should be connected to the outlet of the equipment being drained.

The DN25 (1") - APT14 or DN40 (1½") APT14HC and APT14SHC port should be connected

to the condensate return line. Flow arrows indicate the correct direction of flow. The DN15

(½") port marked (S) should be connected to a trapped motive steam supply. * It is

important to ensure this line is drained of condensate at all times using a Spirax

Sarco steam trap and filtered using a 100 mesh strainer as fitted (see Figure 11).

The screwed DN15 (½") port marked (E) should be balanced back as close as possible

to the condensate outlet of the equipment. This balance line must always be connected

to the top of the condensate pipe, as shown in Figure 11. Note: If a thermal cut out device

has been installed to protect the heat exchanger from excess temperature, then it is

important this is mounted upstream of the steam control valve and the take-off point for

the motive steam supply to the APT14, APT14HC or APT14SHC.

Filtered / trapped motive steam supply line

Removable flanged or union section for

ease of maintenance

Spirax

Sarco

APT14

•

Ensure this

steam line is

correctly drained

of condensate at

all times using a

Spirax Sarco steam

trap plus the 100

mesh strainer as

fitted to the pump

to prevent debris

entering the pump

mechanism.

Fig. 12

Suggested coupling of

motive supply and exhaust

lines

250 mm (APT14)

275 mm (apt14hc

275 mm (APT14SHC)

minimum withdrawal

distance

Loading...

Loading...