23

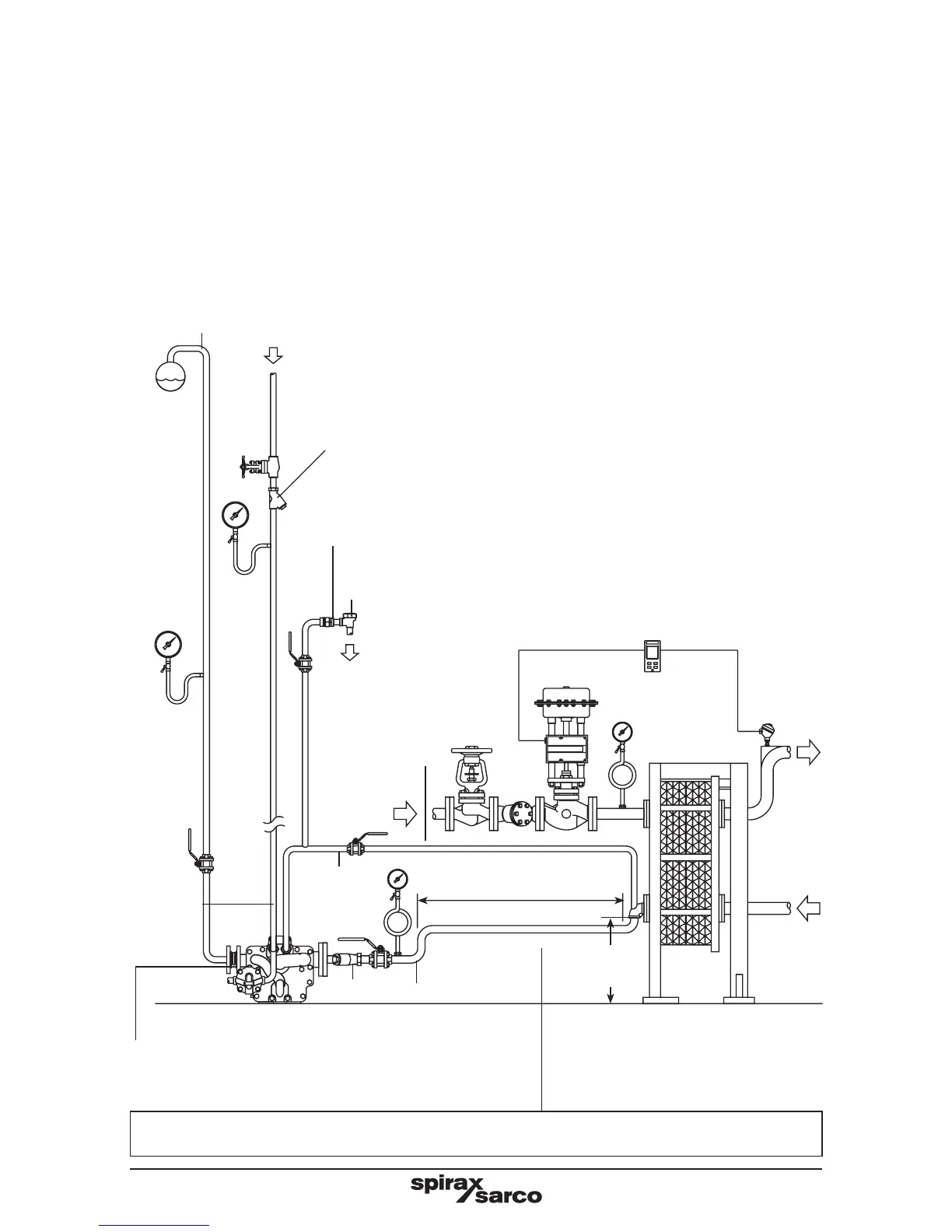

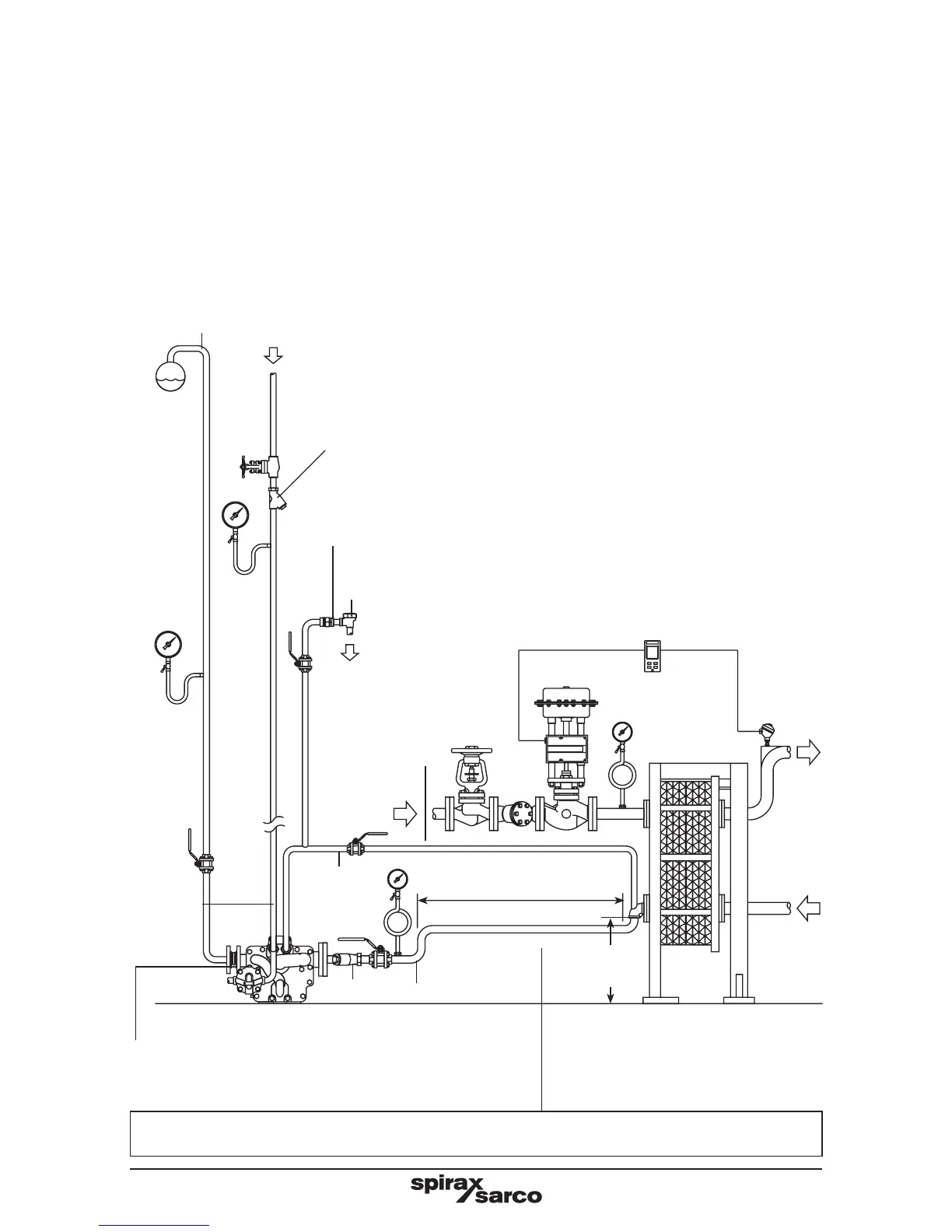

4.4 Outlet piping

It is important for the outlet piping to be correctly sized to prevent excessive backpressure

on the APT14, APT14HC or APT14SHC. This pipework should be sized to take into account

the effects of flash steam at the heat exchangers full load operating conditions and any

other equipment being discharged into the return line.

Note: A separate Spirax Sarco DN40 DCV10 check valve must be fitted to the outlet flange

of the pump body and the connecting pipework flange - APT14HC and APT14SHC only.

Ensure the DCV10 is mounted centrally between the flanges with the directional flow arrow

pointing in the direction of fluid flow. A gasket should be used both sides of the disc check

valve. For all other maintenance and technical information see IM-P601-32.

Motive IN

Strainer fitted with 100 mesh screen.

Note: The APT's are all supplied with a strainer close coupled

to the steam inlet connection.

Condensate outlet

Spirax Sarco sized length

of pipe to act as a reservoir

Balance

line

Exhaust

OUT

Condensate inlet

Strainer

Outlet DCV10 between flanges

(APT14HC and APT14SHC only)

An air vent must be fitted higher than the inlet to the process.

†

Fig. 13

*Trapped motive steam supply

Soft sealing flanged or screwed DCV

0.2 m

(8")

It is recommended that the reservoir be installed at least 1 pipe diameter below the

process outlet, but as high as possible above the APT14, APT14HC or APT14SHC inlet.

† Minimum installation head

0.2 m (8") from base of pump.

Recommend minimum 0.3 m,

maximum 1 m.

Loading...

Loading...