26

5.1

After ensuring the inlet and outlet pipe connections and motive/exhaust connections

are coupled in accordance with Figures 15 and 16, slowly open the motive steam inlet

line to supply pressure to the APT14, APT14HC or APT14SHC. Ensure the exhaust/

balance line is open and not restricted in any way.

5.2

Slowly open the isolation valves in the condensate inlet and discharge lines, allowing

condensate to fill the body of the APT14, APT14HC or APT14SHC.

5.3

The APT14, APT14HC or APT14SHC is now ready to operate.

5.4

When the process plant is operational, the APT14, APT14HC or APT14SHC will

discharge condensate under all pressure conditions into the return line.

5.5

If any irregularities are observed, recheck the installation according to the

recommendations in Section 4. If the unit fails to operate, then consult the fault finding

guide Section 9.

5. Commissioning

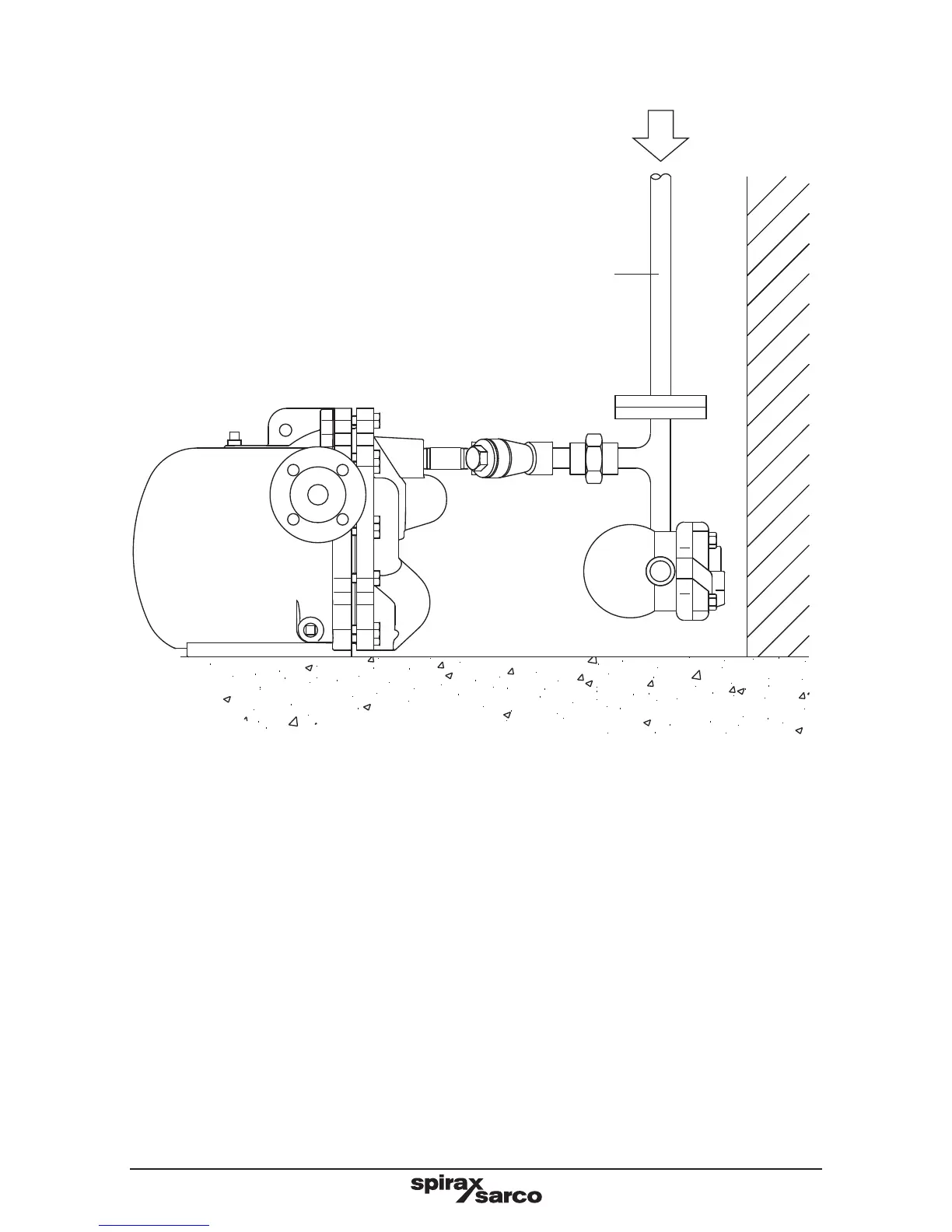

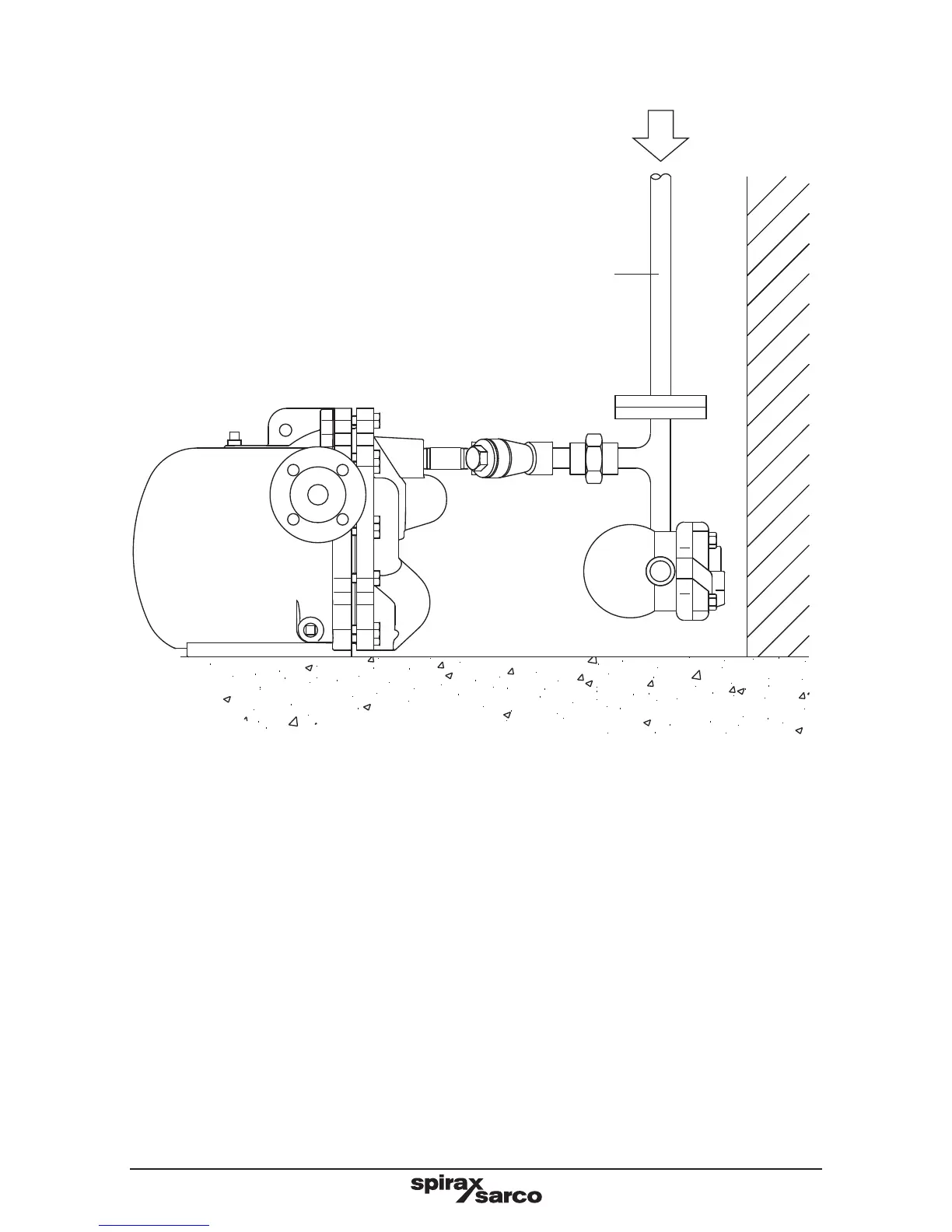

Fig. 16

Filtered / trapped motive steam supply line

Spirax

Sarco

APT14

Ensure this steam line is correctly drained of condensate at

all times using a Spirax Sarco steam trap plus the 100 mesh

strainer as fitted to the pump to prevent debris entering the

pump mechanism.

Loading...

Loading...