3

1. Before installation, inspection or maintenance, the

trap must be isolated from both supply and return

line pressure.

2. The trap should be installed below the drainage

point of the equipment or steam main so that

condensate can flow by gravity into the trap. A

vertical drop to the trap is advantageous, but long

horizontal runs should be avoided because of the

possibility of steam locking. If a long horizontal

run to the trap is unavoidable, a trap with a steam

lock release should be used.

3. If possible, a drop leg and dirt pocket should be

installed ahead of the trap. The trap should be

protected by a Spirax Sarco y-pattern stainer,

preferably fitted with a blow down valve. Full-port

isolating valves should be installed to permit ser-

vicing.

4. The trap must be installed in an upright posi-

tion with the orientation arrow on the body or on

the nameplate pointing straight down. The flow

direction markings on the body or cover must be

observed.

5. Before installing the trap, the inlet piping should

be carefully blown down to remove any existing

debris.

6. A Spira-tec

®

sensor chamber facilitates checking

the trap’s operation. A check valve downstream of

the trap will prevent backflow from the return line.

Installation

Description and Operation

Spirax Sarco Float & Thermostatic Steam Traps are ideally suited for most HVAC and process applications. The

spherical stainless steel float automatically adjusts the position of the main valve so that condensate is discharged

continuously at the same rate as it enters the trap. Air and other non-condensible gases which are present at start up

or which enter the trap during operation are discharged through the integral balanced pressure thermostatic air vent

(some high pressure F & T traps have a bimetal air vent). The traps will operate against any back-pressure lower than

the inlet pressure. (The differential pressure—inlet pressure minus outlet pressure—determines the trap’s capacity).

All Spirax Sarco F & T traps will tolerate at least 450°F of temperature. The superheat tolerance of some models is

higher; refer to the appropriate Technical Information Sheet or call Spirax Sarco for further information.

Limiting Operating Conditions

The maximum operating pressure (PMO) is shown on the nameplate. The PMO depends on the valve mechanism;

if the pressure at the trap inlet is higher than the PMO, the excess pressure may lock the valve closed. In some cases

(for example, if there is a permanent back-pressure in the return line) in may be permissible to exceed the PMO.

Please consult Spirax Sarco for details.

The maximum operating temperature depends on the superheat tolerance of the air vent. This is always at least

450°F as the TMA (see below) is not exceeded.

The maximum allowable pressure and temperature (PMA and TMA) are determined by the pressure shell design

conditions, and must not be permanently exceeded. The trap may be subjected to a temporary cold hydraulic test

pressure of 1-1/2 times the cold PMA, provided that the air vent is first removed. If the test pressure will exceed 600

psi, the float must also be removed.

7. If the condensate must be lifted to the return

main, the trap, followed by a check valve, should

be installed at the bottom of the lift. Sufficient

pressure to lift the condensate (approximately 1

psi for each 2 ft. of lift) must be present at the trap

inlet at all times.

Note that a temperature control valve on the

inlet steam may at times reduce the pressure

below the amount required to lift the condensate.

When the inlet steam is controlled and conden-

sate must be lifted after the trap, a Spirax Sarco

Pressure Powered Pump™ should be considered.

8. Bypass piping is not recommended because of

the possibility of misuse. If continuous service is

required, a second trap could be piped in paral-

lel with suitable valving to allow one trap to be

serviced while the other remains in operation. If

a bypass line must be used, it should be at least

one pipe size smaller than the trap.

9. Because condensate cannot drain completely

from the body, an F & T trap installed outdoors

can freeze up if it is not in continuous operation.

If there is a possibility of an interruption in the

steam supply, provisions should be made for

draining or tracing the trap body.

10.The trap can be put into service by slowly opening

the isolating valves. No priming is necessary.

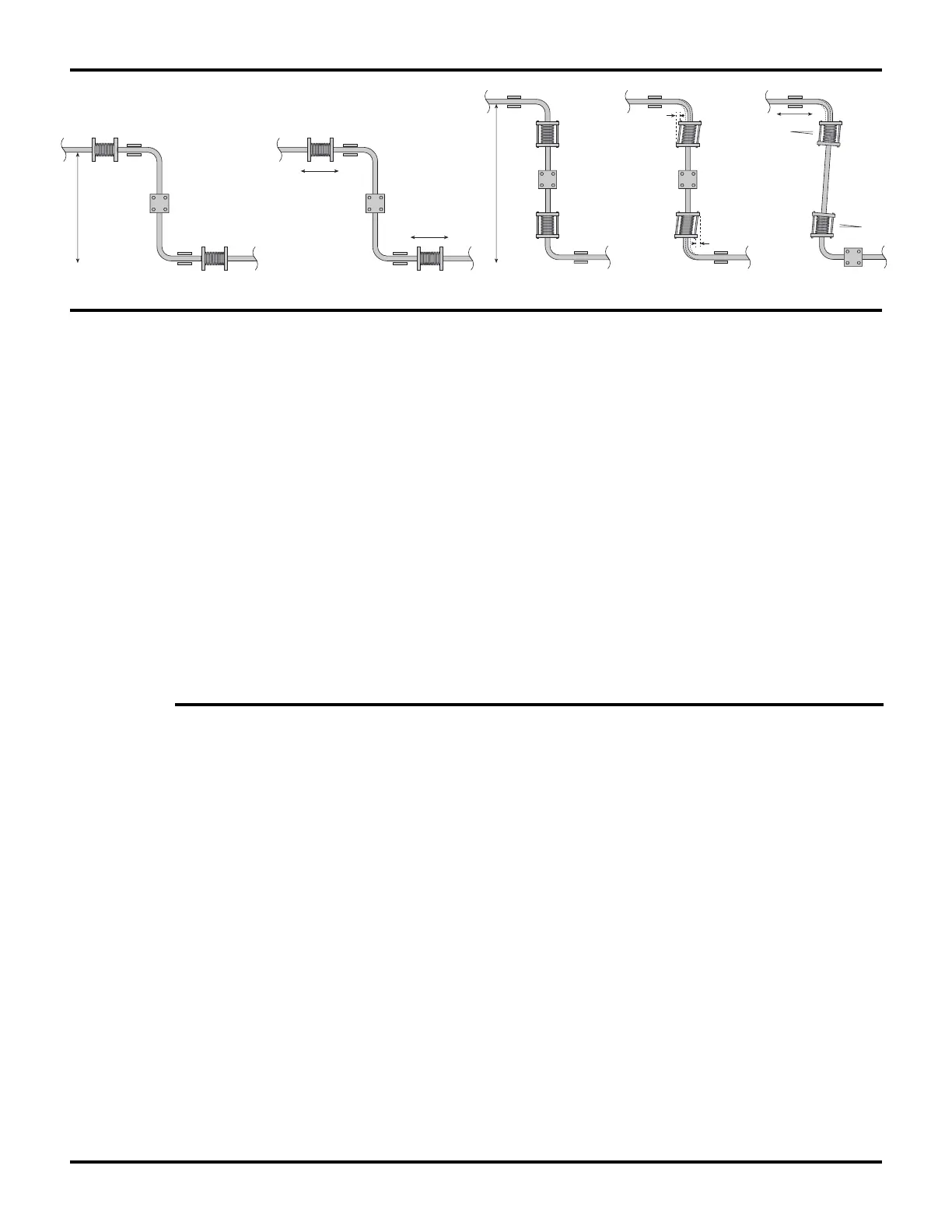

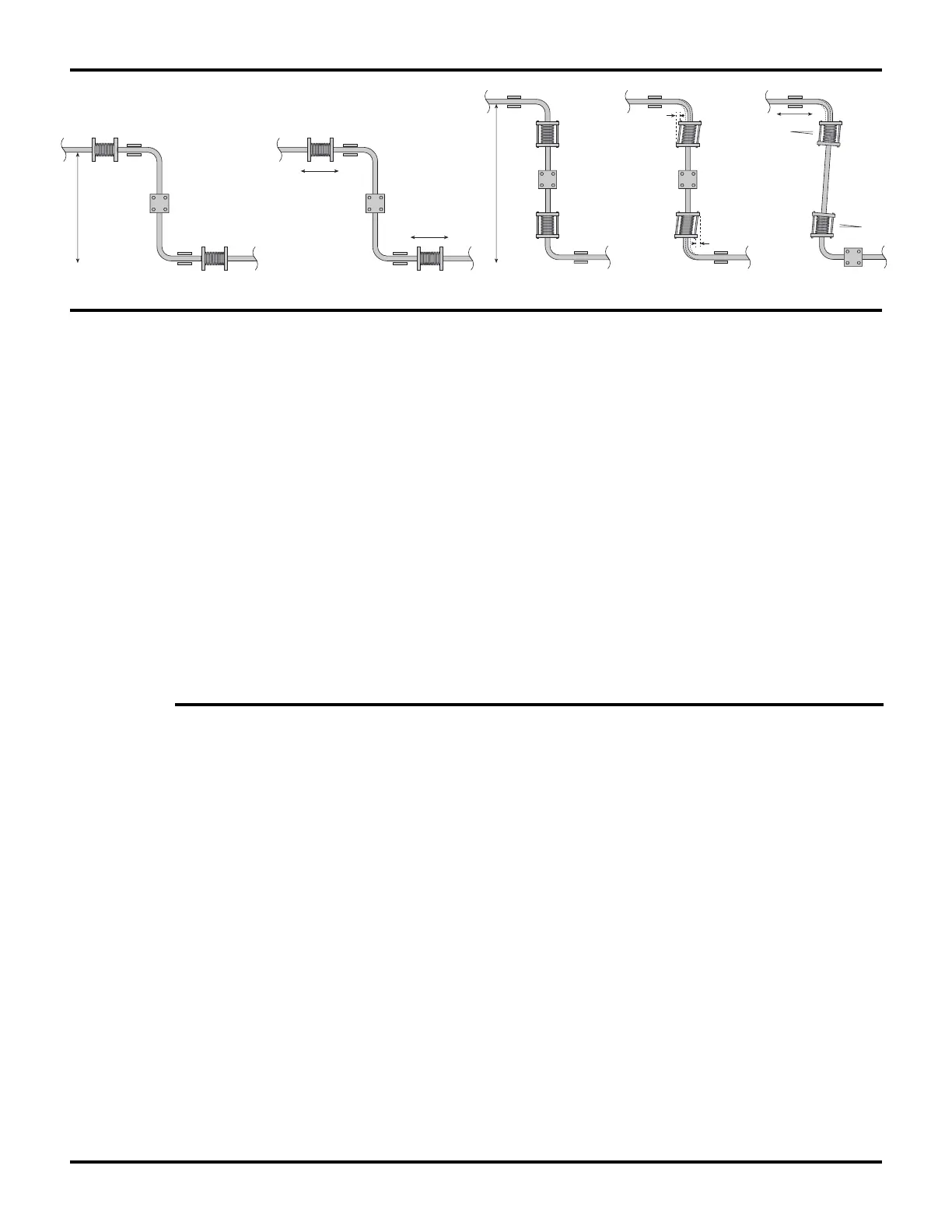

Thermal expansion:

Short

distance

Fixing point

Axial movement

Axial movement

Guides

Guides

Guides

Guides

Limit rods

Limit rods

Fixing point

Medium

distance

Small

lateral

movement

Small

lateral

movement

Large

lateral

movement

Large

lateral

movement

Loading...

Loading...