4

Maintenance

1. After isolation from supply and return line pres-

sure, all Spirax Sarco F & T traps can be serviced

without disturbing the piping connections. On some

models the cover with mechanism attached can be

removed for servicing while the body remains in the

pipeline.

2. On most models, dirt and sludge which may accu-

mulate in the trap can be removed by “blowing

down” through the drain plug in the bottom of the

body.

3. The trap should be disassembled periodically for

inspection and replacement if necessary of the

valve mechanism and air vent.

4. Ensure that the trap is properly isolated, and that

any pressure which may remain in the trap is

relieved before the trap is opened. This can be

accomplished by opening the blowdown valve on

the upstream strainer and waiting until the trap has

cooled. Some condensate will remain in the trap

body. This can be drained by removing the drain

plug or by cracking the body-cover joint.

5. Remove and save the cover bolts, and remove

the body or cover. Using a suitable solvent, clean

all dirt and incrustation from the body, cover and

mechanism. Inspect the body and cover for con-

densate corrosion.

6. Inspect the valve head and seat for damage, wear

or wiredrawing. Replace the mechanism if neces-

sary, using a complete valve mechanism kit and

following the instructions included with the kit.

7. Inspect the float for leakage or damage, and

replace if necessary. A distorted or collapsed float

is evidence of a severe and dangerous overpres-

sure or waterhammer condition which must be cor-

rected before the trap is returned to service.

8. The air vent should be removed, tested for proper

operation, and replaced if necessary. Instructions

are included with the air vent kit.

9. Remove all traces of the old gasket from the body

and cover, and ensure that the gasket surfaces are

clean and undamaged. Using a new cover gasket,

reassemble the trap. Tighten the cover bolts to the

torque shown on page 3.

10.The trap can be returned to service by slowly open-

ing the isolating valves. Priming is not required.

Note: Flash steam is formed when a portion of the

hot condensate re-evaporates as it passes from

a higher to a lower pressure (for example, as it

flows through a steam trap). This flash steam is

normal, and it should not be mistaken for live steam

leakage when the operation of the trap is being

observed.

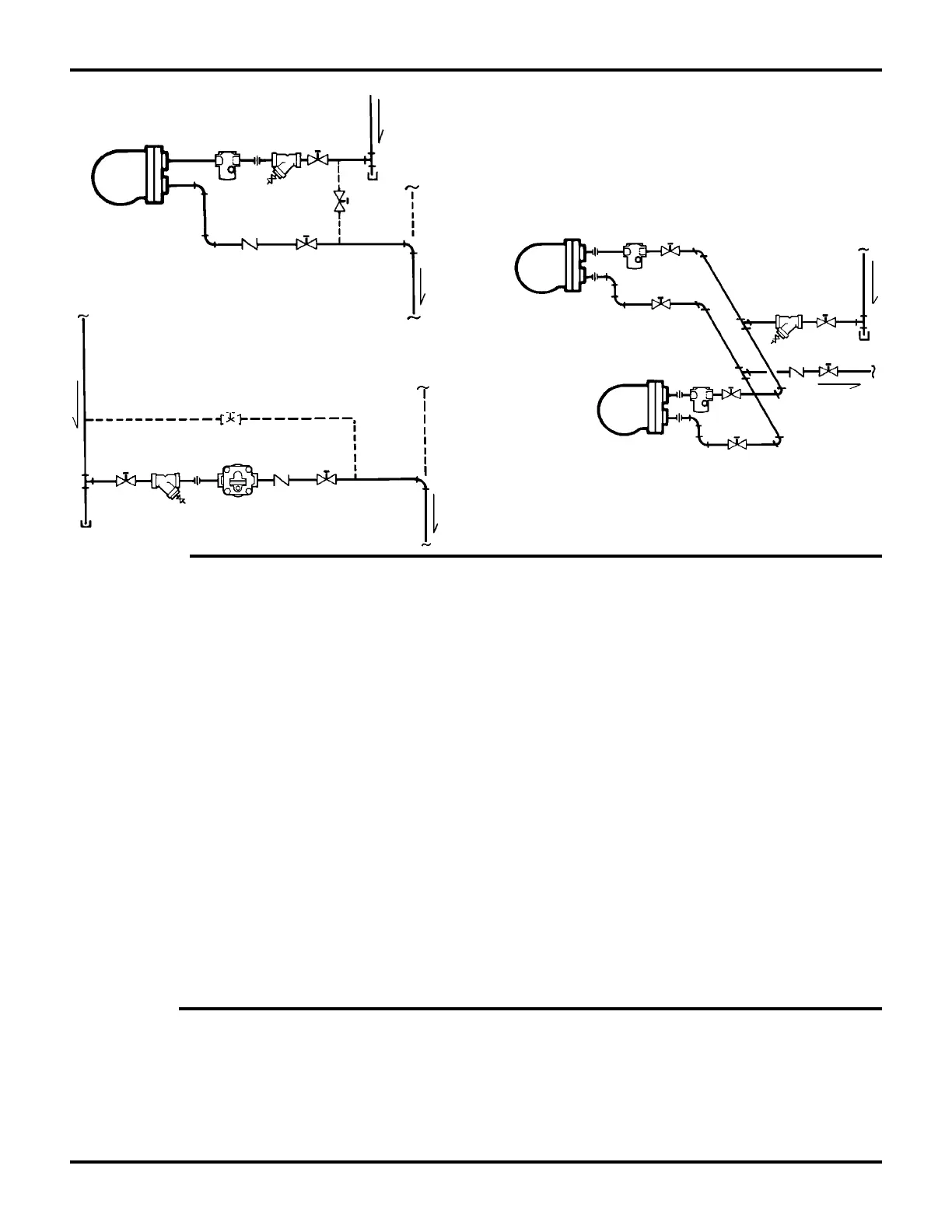

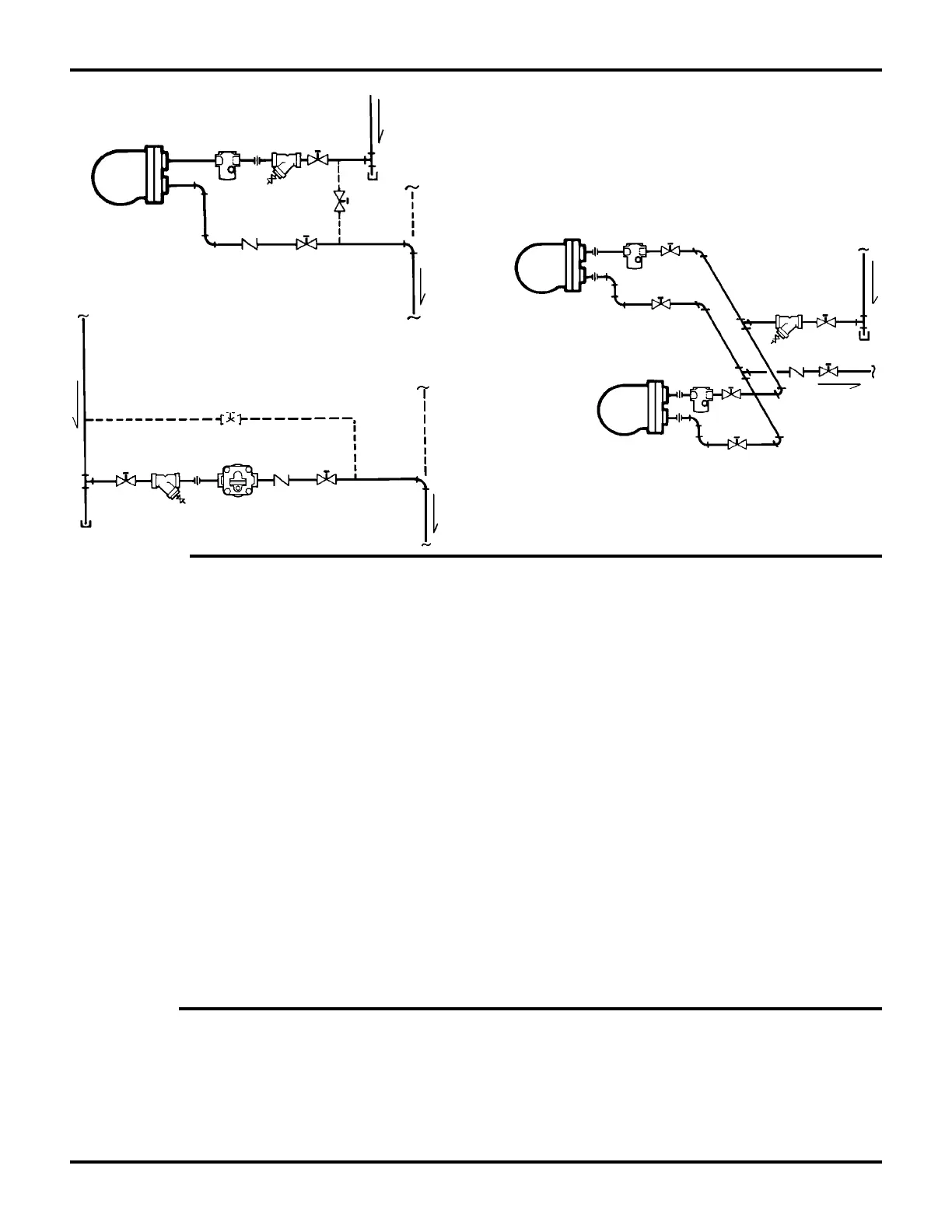

Horizontal Inline Type

Parallel Trap Installation

(No Bypass)

Parallel Type

Bypass

if required

Spira-Tec

C.V.

Bypass

if required

Str.

C.V.

Str.

Spira-Tec

C.V.

Spare Parts

The following spare parts are available for Spirax Sarco

Float & Thermostatic Steam traps:

Valve Mechanism Kit - Complete valve mechanism

with mechanism gasket and mounting screws as

required. A separate cover gasket kit should be

ordered when replacing mechanism parts.

Gasket Kit - Three each of cover and mechanism gaskets.

Air Vent Kit - Air vent assembly.

Replacement Kit - Valve mechanism with gasket, float

with screw and washer, air vent assembly, cover gasket.

Float Kit - Float with screw and lockwasher as required.

Note: In some models, the float is welded to the

mechanism arm, and is included in the valve

mechanism kit. A separate float kit is not available.

Loading...

Loading...