IM-S02-30 CMGT Issue 14

19

FT43, FT44, FT46 and FT47 Ball Float Steam Traps

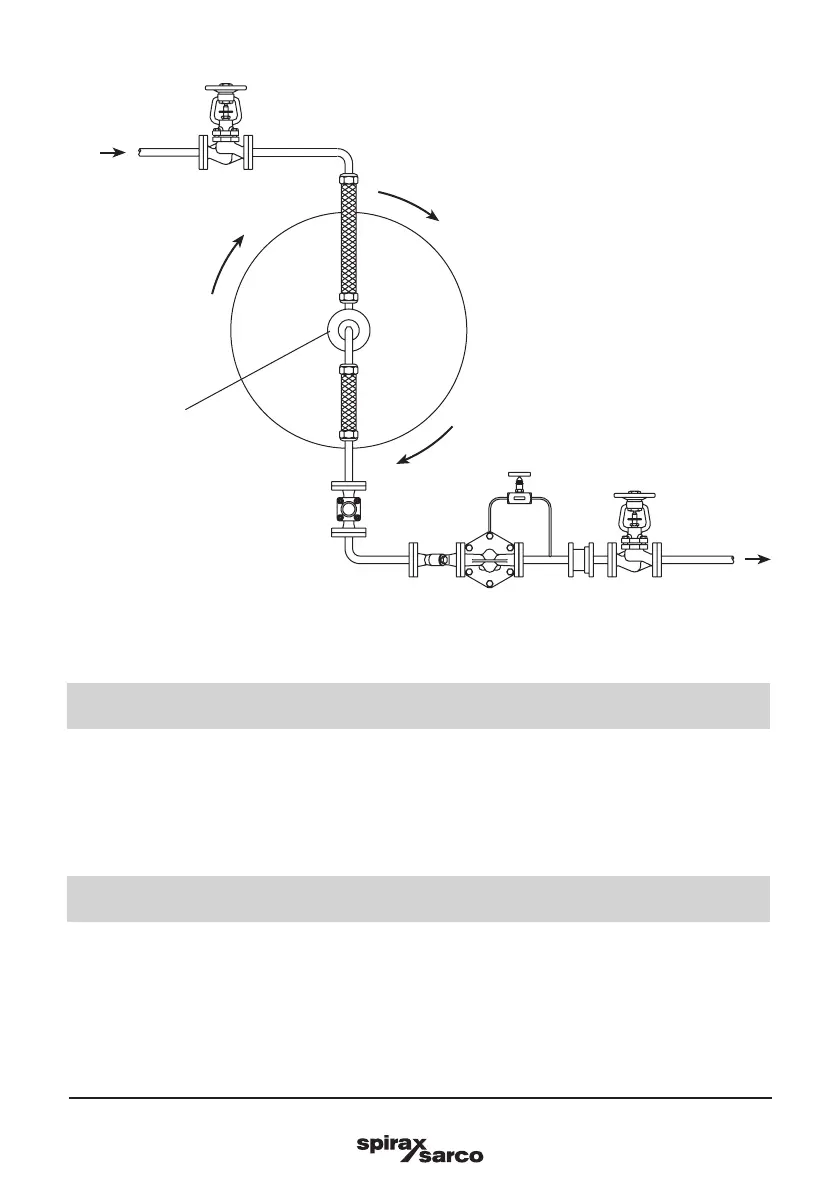

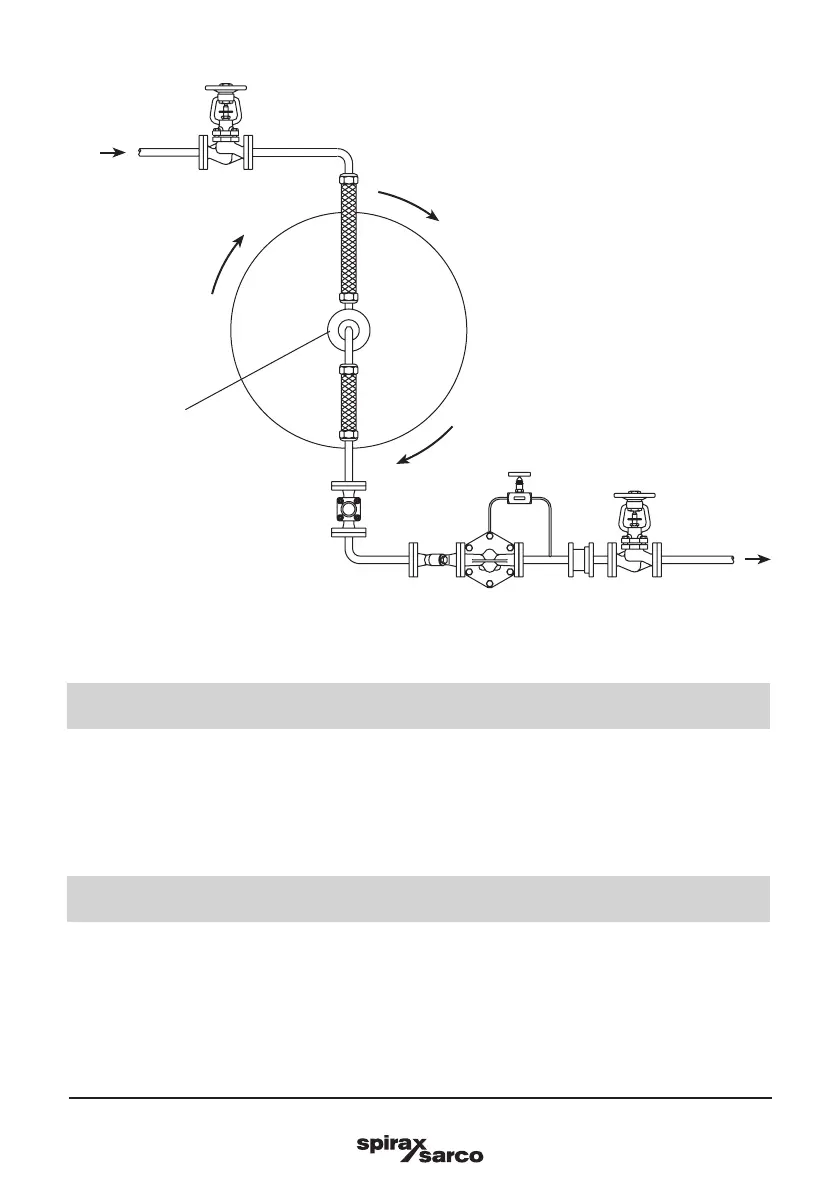

Fig. 8

High speed cylinder with float trap

and parallel blow-through valve

Rotating cylinder

Float trap with

external bypass

Steam in

Rotary joint with

flexible couplings

Condensate

out

After installation or maintenance ensure that the system is fully functioning. Carry out tests on any alarms

or protective devices.

The float trap is a continuous trap, removing condensate the instant it forms. On start-up, the thermostatic

air vent allows air to bypass the main valve preventing the system air binding. Hot condensate will close the

air vent tightly, but as soon as it enters the main chamber of the trap, the float rises and the lever mechanism

attached to it opens the main valve - keeping the system drained of condensate at all times. When the steam

arrives, the float drops and closes the main valve. Float traps are renown for their high start-up load handling

capability, clean tight shut-off and resistance to waterhammer and vibration.

4. Commissioning

5. Operation

3.9

Ensure adequate space is left to

remove the cover from the body

for maintenance – the maximum

withdrawal to remove the cover is

200 mm (8").

Note:

If the trap is to discharge to atmosphere

ensure it is to a safe place, the discharging

fluid may be at a temperature of 100 °C

(212 °F).

Loading...

Loading...