_____________________________________________________________________________________________

Spring Air Systems Water Wash Ventilator Maintenance Manual 11/01

28

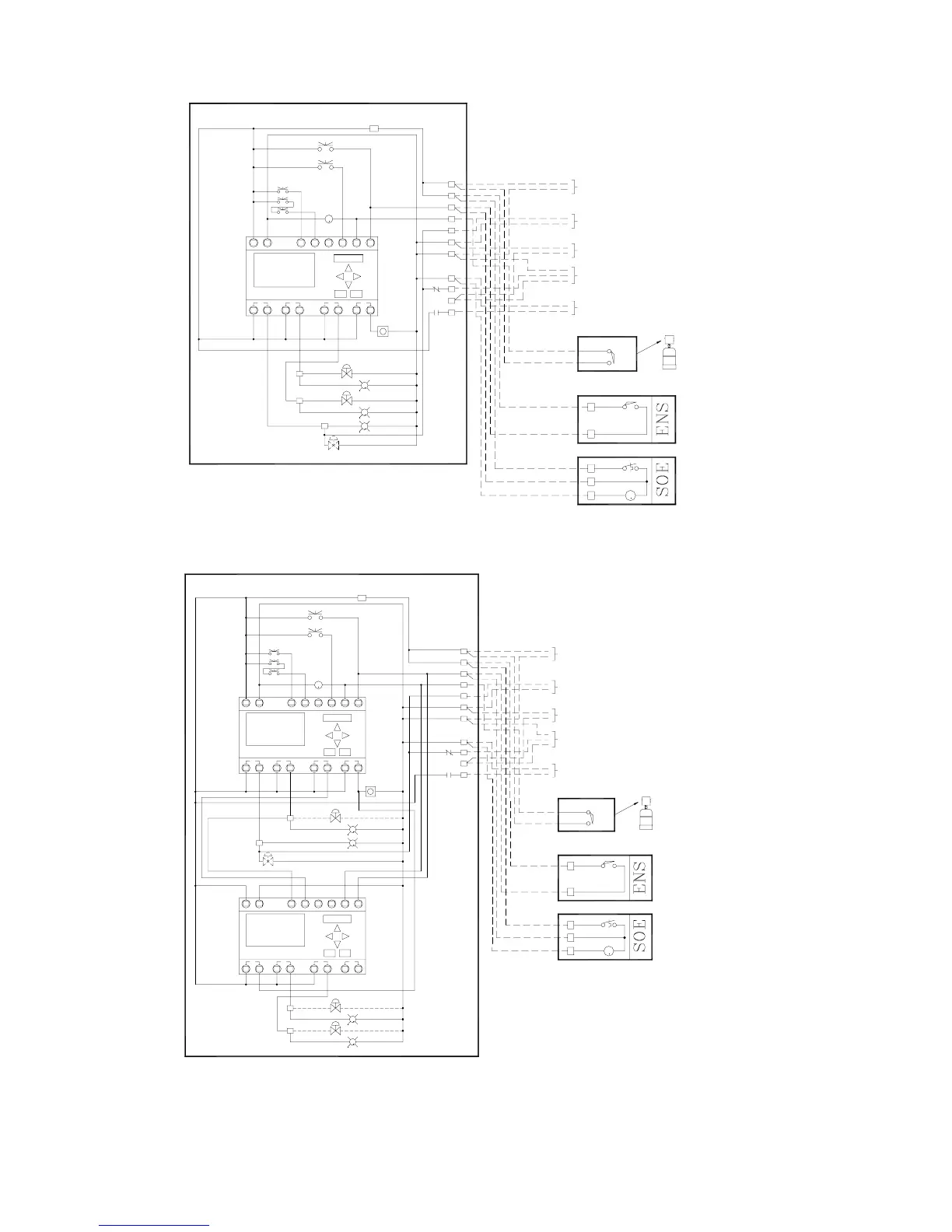

AP20C & AP20H two sequence electrical wiring

Figure 36

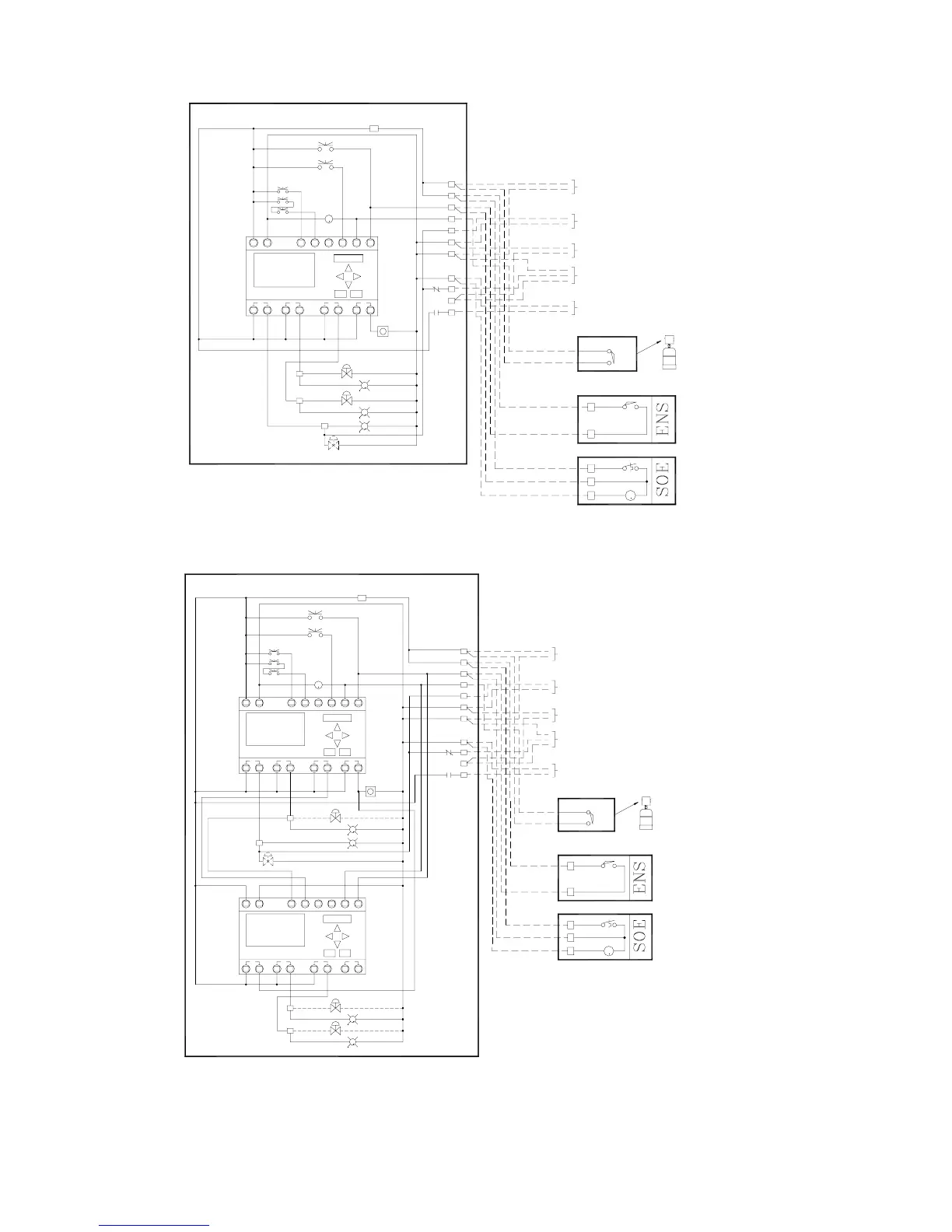

AP30C & AP30H three sequence electrical wiring

Figure 37

I1

Q: 1 2 3 4 RUN

SMART RELAY

INTERNAL WIRING BY SPRING AIR

H2

H1

Set clock

and length

wash here.

B02=WASH2

B01=WASH1

B04=CLOCK

of first

Mo 09:00

Q1 Q2

I: 1 2 3 4 5 6

LN

OFF/AUTO/ON

FAN SWITCH

REMOTE WIRING BY TRADES

120V/1/60 - 2 AMPS MAXIMUM.

24 HOURS/DAY - 120V/1/60 - 15 AMPS

POWER SUPPLY TO THE AP20H/C PANEL

2 AMPS MAXIMUM.

RELAY SUPPLIED AND INSTALLED BY ELECTRICAL DIVISION)

120V/1/60 - 2 AMPS MAXIMUM. (SHUNT TRIP OR

COOKING EQUIPMENT IN THE EVENT OF A FIRE

POWER TO SHUNT TRIP TO DE-ACTIVATE ELECTRIC

SHUTOFF DAMPER AND END SWITCH 120V/1/60

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

POWER TO THE EXHAUST FAN MOTOR STARTER

DAMPER END SWITCH

REMOTE WIRING FOR ARRANGEMENT "F" & "T" TYPE FIRE DAMPER HOODS

ONLY. ARRANGEMENT "D" FIRE DAMPER HOODS REQUIRES NO REMOTE WIRING.

FAN PILOT

C

WATER SOLENOID

G

OPTIONAL COLD

WASH PILOT #1

HOT WATER SOLENOID #1

HOT WATER SOLENOID #2

WASH PILOT #2

B

B

DETERGENT

PUMP

2

4

2

1

1

WHITE

RED

5

1

R5

ESC

Q3 Q4

OK

I2 I3 I6I4 I5

R5

R5

CURCUIT BREAKER

FIRE TEST

PUMP TEST

3

5

4

8

9

10

4

3

4

4

8

9

4

10

4

4

9

1

1

2

4

1

OR

ARRANGEMENT "T" FIRE DAMPER:

ARRANGEMENT "F" FIRE DAMPERS:

TWO (2) WIRES TO THE

WET CHEMICAL CONTROL

HEAD 120V/1/60 - 1A.

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

FENWALL DETECTOR

DAMPER SOLENOID

END SWITCH

NORMALLY OPEN

OR

x

x

o

x

ox

o

ox

H2

H3

WASH PILOT #3

WASH PILOT #2

HOT WATER SOLENOID #3

HOT WATER SOLENOID #2

B

B

I1

Q: 1 2 3 4 RUN

SMART RELAY

INTERNAL WIRING BY SPRING AIR

I1

SMART RELAY

Q: 1 2 3 4 RUN

H1

Set length

wash here.

and third

of second

B03=WASH3

B02=WASH2

Q1 Q2

I: 1 2 3 4 5 6

LN

C

N

Set clock

L

B01=WASH1

B04=CLOCK

wash here.

and length

of first

Q1 Q2

Mo 09:00

I: 1 2 3 4 5 6

FAN SWITCH

OFF/AUTO/ON

ALL HOT WATER SOLENOID VALVES

ARE LOCATED REMOTE FROM PANEL

POWER SUPPLY TO THE AP20H/C PANEL

24 HOURS/DAY - 120V/1/60 - 15 AMPS

REMOTE WIRING BY TRADES

POWER TO THE EXHAUST FAN MOTOR STARTER

120V/1/60 - 2 AMPS MAXIMUM.

LV10 PANEL - 120V/1/60 - 2 AMPS MAXIMUM.

(OPTIONAL) POWER SUPPLY TO SUPPLY FAN

MOTOR STARTER - 120V/1/60 - 2 AMPS MAXIMUM

SHUTOFF DAMPER AND END SWITCH 120V/1/60

2 AMPS MAXIMUM.

POWER TO SHUNT TRIP TO DE-ACTIVATE ELECTRIC

COOKING EQUIPMENT IN THE EVENT OF A FIRE

120V/1/60 - 2 AMPS MAXIMUM. (SHUNT TRIP OR

POWER TO THE SPRING AIR SYSTEMS ENVIRO FILTER UNIT

(OPTIONAL) THREE (3) WIRES TO SUPPLY AIR MOTORIZED

RELAY SUPPLIED AND INSTALLED BY ELECTRICAL DIVISION)

DAMPER END SWITCH

REMOTE WIRING FOR ARRANGEMENT "F" & "T" TYPE FIRE DAMPER HOODS

ONLY. ARRANGEMENT "D" FIRE DAMPER HOODS REQUIRES NO REMOTE WIRING.

ESC OK

Q3 Q4

I3I2 I6I4 I5

HOT WATER SOLENOID #1

WASH PILOT #1

WATER SOLENOID

OPTIONAL COLD

FAN PILOT

B

G

4

1

2

1

2

5

WHITE

RED

1

I6I4I3I2 I5

ESC OK

Q3

Q4

DETERGENT

PUMP

R5

FIRE TEST

PUMP TEST

8

10

9

R5

4

4

R5

4

4

10

9

4

8

4

9

1

1

2

3

5

4

4

3

1

NORMALLY OPEN

WET CHEMICAL CONTROL

TWO (2) WIRES TO THE

OR

ARRANGEMENT "F" FIRE DAMPERS:

TWO (2) WIRES TO EACH ENS ENCLOSURE LOCATED

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

ARRANGEMENT "T" FIRE DAMPER:

AT EACH EXHAUST DUCT COLLAR ON EVERY HOOD

120V/1/60 - 1 AMPS. WIRE EACH ENS IN PARALLEL.

THREE (3) WIRES TO EACH SOE ENCLOSURE LOCATED

120V/1/60 - 3 AMPS - WIRE EACH SOE IN PARALLEL.

HEAD 120V/1/60 - 1A.

FENWALL DETECTOR

DAMPER SOLENOID

END SWITCH

OR

CURCUIT BREAKER

x

x

o

x

ox

o

ox

Loading...

Loading...