© SPX FLOW, Inc.

Form No. 1000623

Rev. 6 Jan. 10, 2017

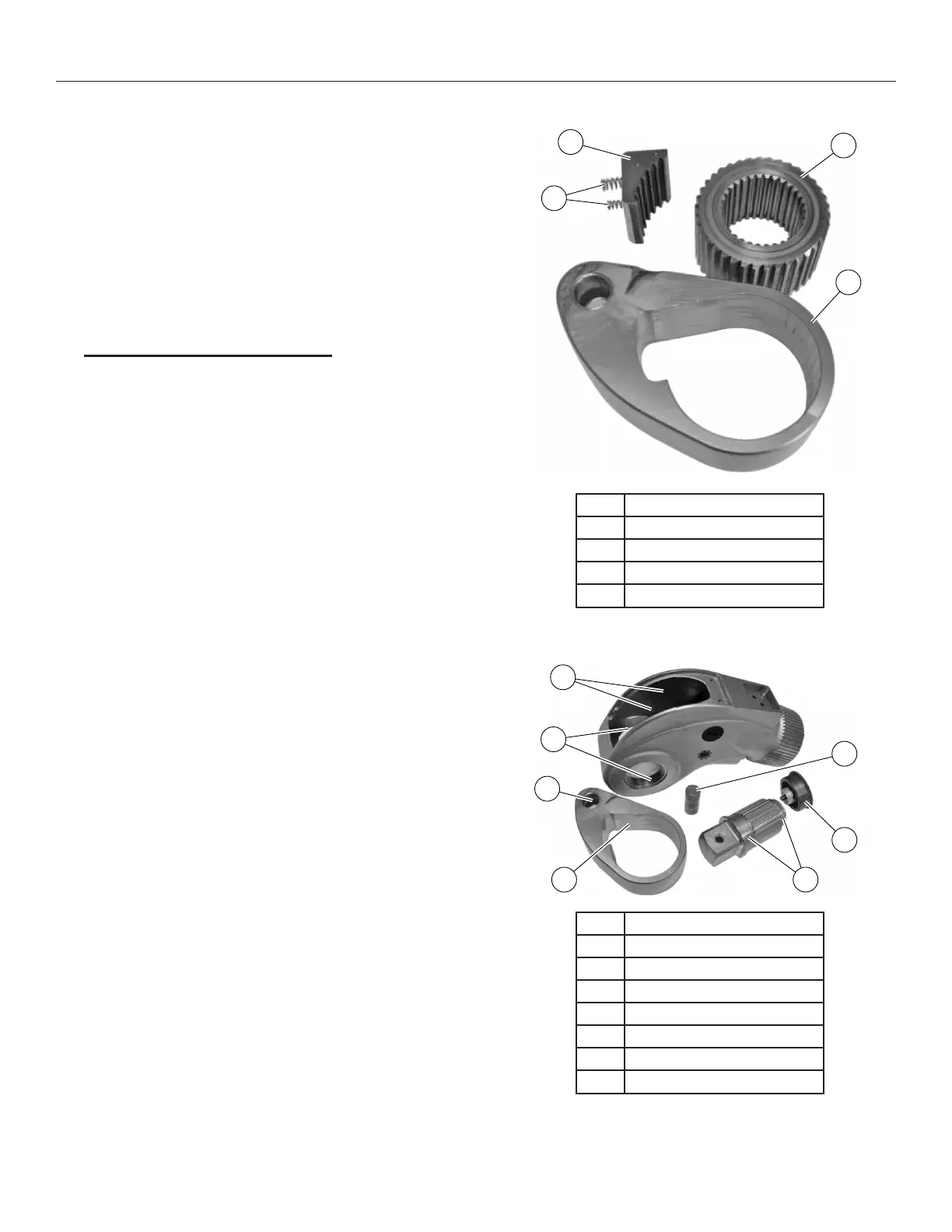

7. See Figure 9. Remove the ratchet, drive shoe and

springs from the crank.

8. Thoroughly clean all components, removing the old

lubricant using a mild degreasing agent. Inspect all

components for damage and/or excessive wear.

Inspect the ratchet and drive shoe teeth for damage,

cracks, etc. Any substandard component must be

replaced immediately using genuine parts supplied

by SPX Bolting Systems.

Drive Component Assembly

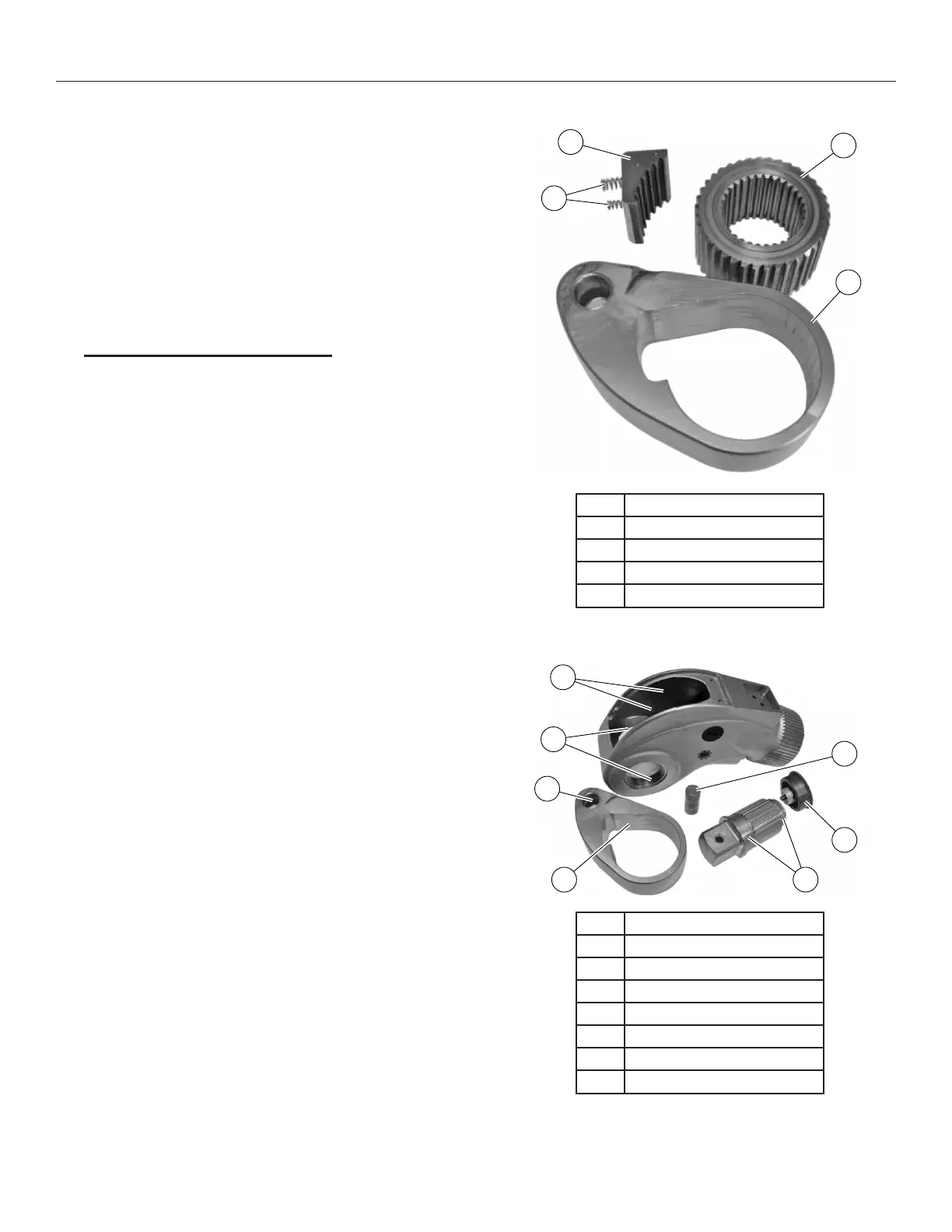

See Figure 10. Before assembly, apply a liberal coat of

Revol R5 Moly Anti Seize to the following areas:

• Body internal sideplates (where the crank

contacts).

• Crank bearings.

• Crank pocket where the drive shoe is located

(not the crank bore).

• Body sideplate journals.

• Square drive bearings.

• Square drive cap bearing.

IMPORTANT: Do not apply lubricant to the ratchet

and drive shoe teeth.

The hydraulic torque wrench drive components must

be lubricated using the specied product only. Using

alternative lubricants will affect the output and possibly

lead to premature component failure.

1. Place the drive shoe and springs into the crank

pocket and install the ratchet ensuring the springs

do not tilt. Verify that the ratchet teeth are driving in

the correct direction and are engaged with the drive

shoe teeth. Rotate the ratchet to ensure correct

operation.

2. Install the drive assembly into the wrench body,

centralise the crank pin hole in the body plug hole

and install the crank pin.

3. Press the drive assembly downwards to centralise

the ratchet in the sideplate journals.

4. Slide the square drive into the wrench body and

attach the square drive cap.

5. Install both body plugs

6. Ret the guard.

Repair Procedures continued

1

2

3

4

Item Description

1 Springs

2 Drive Shoe

3 Ratchet

4 Crank

Figure 9. Drive Disassembly

1

2

3

5

7

6

4

Item Description

1 Body Internal Sideplates

2 Crank Pin

3 Square Drive Cap Bearing

4 Square Drive Bearings

5 Crank Pocket

6 Crank Bearings

7 Sideplate Journals

Figure 10. Lubrication Areas

Loading...

Loading...