Waukesha Cherry-Burrell Brand W60/W80 Valves Operation

08/2018 95-03022 Page 17

Pressure Setting Air-To-Raise, Adjustable-Spring Actuator

Do not use vice-grips, channel locks, or pipe wrenches, as dam-

age to the adjustment screw can result.

Remove locknut cover (Figure 7). Using a 1” hex wrench or 1/4”

spanner, turn down the adjustment screw fully, until the stop con-

tacts the actuator can (approx. 8-9 turns).

This is the maximum holding pressure setting. Refer to publi-

cation DS-1201, W60 Series Shut-Off & Divert Valves, for pres-

sure holding charts for the actuator size and valve seat size:

W61, W62, W65 Air-to-Raise.

NOTE: In some cases, the valve seat size may be less than the

body size (reduced-seat options). Be sure to check holding pres-

sures using the correct seat size and actuator diameter size.

To reduce the pressure setting below the maximum, unscrew the

adjustment screw as per Table 2. Check and confirm specific set-

tings with a master gauge under pressure; adjust as required.

Once the setting is achieved, apply a scribe line to the indicator

stem to mark the position.

Actual pressure change per turn of the adjusting screw may be

different due to spring variations.

Air-to-Lower, Adjustable-Spring Actuator

Do not use vice-grips, channel locks, or pipe wrenches, as dam-

age to the adjustment screw can result.

Unscrew the locknut cover (Figure 8 on page 15). The cover will

stay in the yoke area. Using a 1" hex wrench or 1/4" spanner, turn

the adjustment screw in fully, until the stop contacts the actuator

can (approx. 8-9 turns).

This is the maximum holding pressure setting. Refer to publi-

cation DS-1201, W60 Series Shut-Off & Divert Valves, for pres-

sure holding charts for the actuator size and valve seat size:

W63, W62, W65 Air-to-Lower.

NOTE: In some cases, the valve seat size may be less than the

body size (reduced-seat options). Be sure to check holding pres-

sures using the correct seat size and actuator diameter size.

To reduce the pressure setting below the maximum, unscrew the

adjustment screw as per Table 3. Check and confirm specific set-

tings with a master gauge under pressure; adjust as required.

Once the setting is achieved, apply a scribe line to the indicator

stem to mark the position.

Actual pressure change per turn of the adjusting screw may be

different due to spring variations.

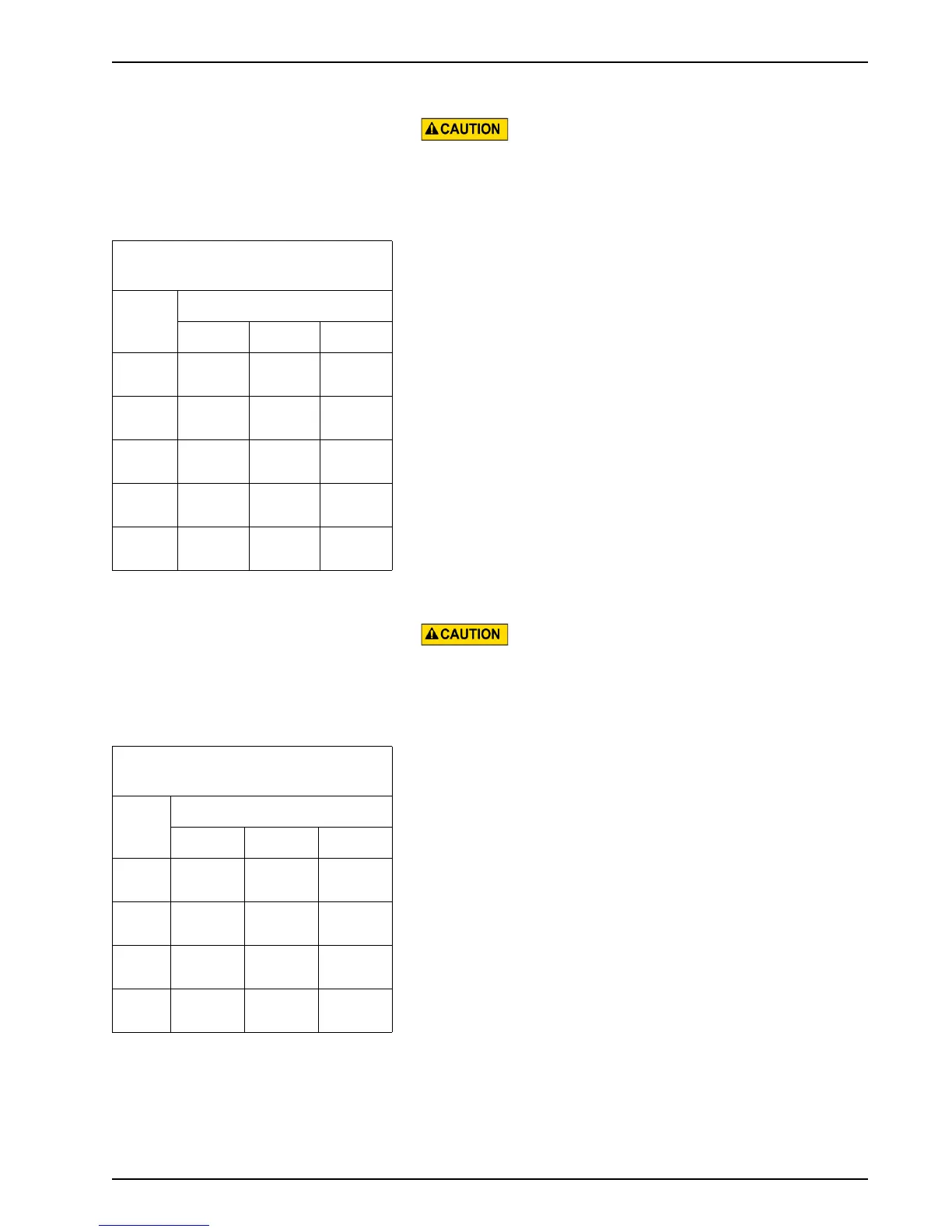

Table 2: Spring Setting for Air-to-

Raise, Adjustable-Spring Actuator

Pressure change per turn of

adjusting screw

Plug

Size

Actuator

4RHAR 5RHAR 6RHAR

1.5"

40 mm

24 40 82

2.0"

50 mm

13 23 46

2.5"

65 mm

9 15 29

3.0"

80 mm

6 10 20

4.0"

100 mm

3 6 12

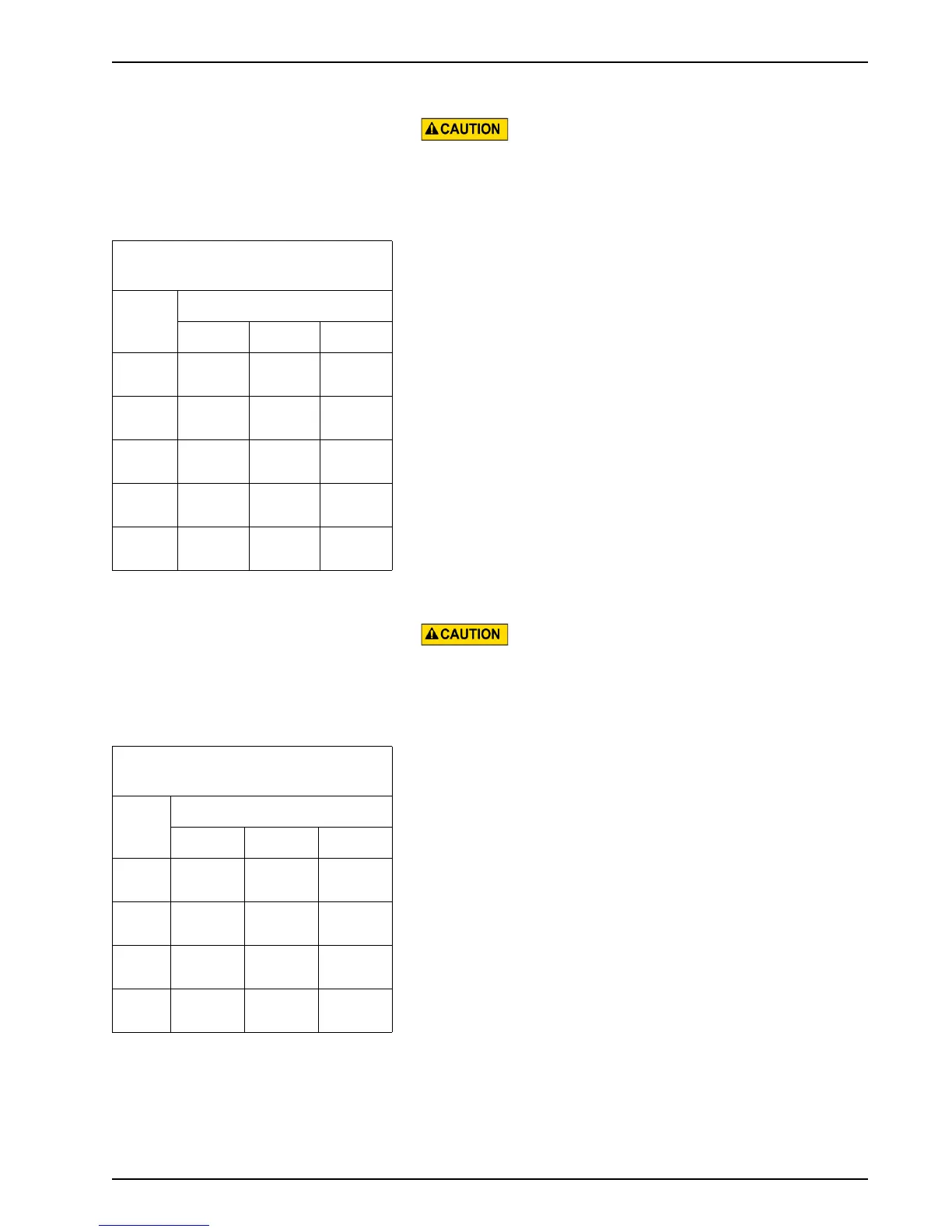

Table 3: Spring Setting for Air-to-

Lower, Adjustable-Spring Actuator

Pressure change per turn of

adjusting screw

Plug

Size

Actuator

4RHAL 5RHAL 6RHAL

2.0"

50 mm

16 26 44

2.5"

65 mm

9 16 27

3.0"

80 mm

6 11 18

4.0"

100 mm

3 6 9

Loading...

Loading...