7

4.0 Operation

4.1 Start-up

A. During the initial start-up, slowly pressurize dryer to full

line pressure and check entire system for leaks. Depres-

surize and correct any leaks.

B. Energize the Dryer On-Off switch located on the enclo-

sure cover (Power-on light should illuminate).

NOTE: If dryer is installed with either internally or externally

mounted air by-pass valve, make certain that by-pass valve is

closed to prevent untreated air from flowing downstream.

4.2 Inlet, Purge, and Outlet Flows @ 100 psig

(7 kgf/cm

2

)

A. Inlet Flows

1. Maximum Inlet Flow at Rated Conditions

For maximum inlet flow at rated conditions refer to

Table 1.

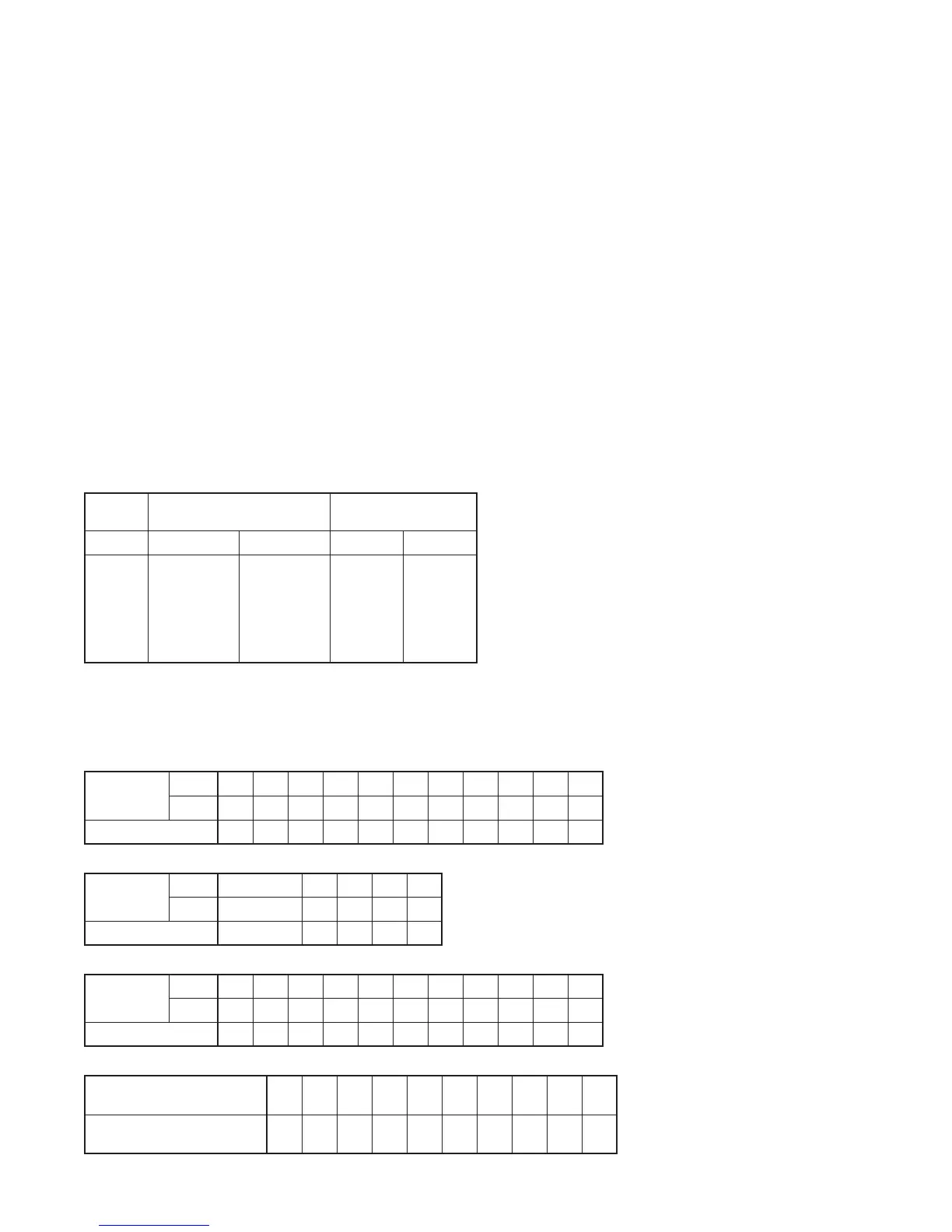

TABLE 1 Inlet and Purge Flows @ 100 psig

MODEL INLET FLOW (1)

scfm (m

3

/h)

PURGE FLOW (2)

scfm (m

3

/h)

-40°F (-40°C) -100°F (-73°C) Average Maximum

7

13

20

25

30

35

50

7.3 (12)

13 (22)

20 (34)

25 (42)

30 (51)

35 (59)

50 (85)

5.6 (9.5)

10 (17)

16 (27)

20 (34)

24 (41)

28 (48)

40 (68)

1.5 (2.5)

2.7 (4.6)

4.2 (7.1)

5.1 (8.7)

6.2 (11)

7.2 (12)

10.2 (17)

2.0 (3.4)

3.7 (6.3)

5.5 (9.3)

6.8 (12)

8.2 (14)

9.6 (16)

13.6 (23)

1. Inlet flows are established in accordance with CAGI (Compressed Air and Gas Institute) standard ADF-200,

Dual Stage Regenerative Desiccant Compressed Air Dryers - Methods for Testing and Rating. Conditions

for rating dryers are: inlet pressure - 100 psig (7 kgf/cm

2

); inlet temperature - saturated at 100°F (38°C).

2. Average Purge Flow is the total amount of air used to purge and repressurize off-stream towers averaged

over the cycle time. Maximum Purge Flow is the flow rate through the off-stream tower during that portion

of the cycle the purge/repressurization valve is open.

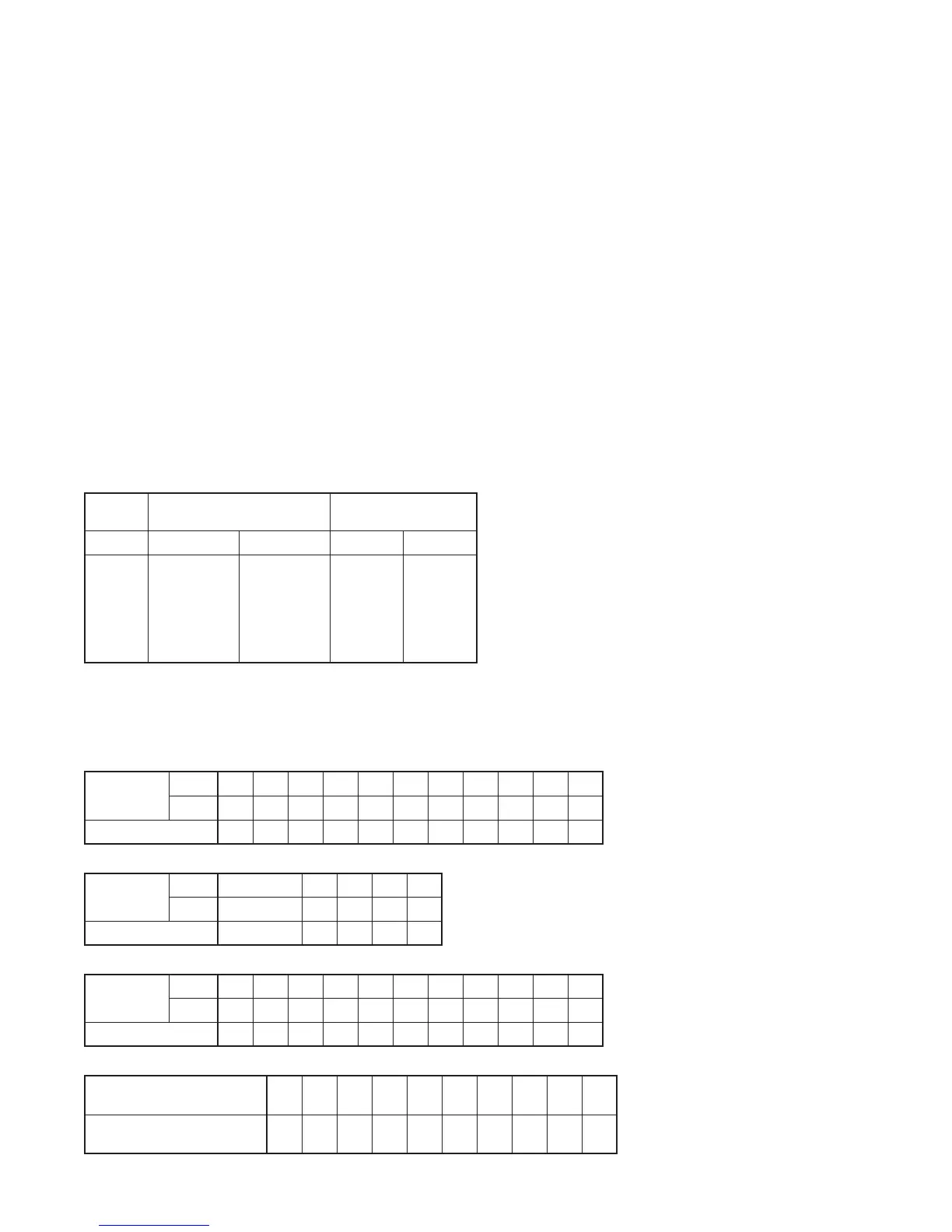

TABLE 2 Capacity Correction Factor for various inlet pressures

INLET

PRESSURE

psig 50 60 70 80 90 100 110 120 130 140 150

kgf/cm

2

3.5 4.2 4.9 5.6 6.3 7.0 7.7 8.4 9.1 9.8 10.5

Multiplier 0.31 0.42 0.54 0.73 0.83 1.00 1.09 1.17 1.26 1.35 1.44

TABLE 3 Capacity Correction Factor for various inlet temperatures

INLET

TEMPERATURE

°F 100 and below 105 110 115 120

°C 38 and below 41 43 46 49

Multiplier 1.00 0.98 0.96 0.93 0.89

TABLE 4 Purge Flow Correction Factor for various inlet pressures

INLET

PRESSURE

psig 50 60 70 80 90 100 110 120 130 140 150

kgf/cm

2

3.5 4.2 4.9 5.6 6.3 7.0 7.7 8.4 9.1 9.8 10.5

Multiplier 0.55 0.64 0.73 0.82 0.91 1.00 1.09 1.17 1.26 1.35 1.44

TABLE 5 Outlet pressure dew points at Moisture Indicator color change

INLET TEMP. °F

(°C)

35

(2)

40

(4)

50

(10)

60

(16)

70

(21)

80

(27)

90

(32)

100

(38)

110

(43)

120

(49)

OUTLET P.D.P. °F

(°C)

-34

(-37)

-28

(-33)

-22

(-30)

-16

(-27)

-10

(-23)

-4

(-20)

3

(-16)

9

(-13)

15

(-9)

21

(-6)

2. Maximum inlet flow at various pressures

To determine maximum inlet flow at inlet pressures

other than 100 psig (7kgf/cm

2

), multiply inlet flow

from Table 1 by multiplier from Table 2 that corre-

sponds to system pressure at inlet of dryer.

3. Maximum inlet flow at various temperatures

To determine maximum inlet flow at inlet tempera-

tures other than 100°F (38°C), multiply inlet flow from

Table 1 by multiplier from Table 3 that corresponds to

system temperature at inlet of dryer.

B. Purge Flow

For maximum and average purge flows at 100 psig

(7 kgf/cm

2

) refer to Table 1.

1. Maximum Purge Flow

Maximum Purge Flow (MFP) is the amount of purge

flowing through the off-stream tower when the

purge/repressurization valve is open. After the purge/

repressurization valve closes, the purge flow will

gradually decrease as the off-stream tower repres-

surizes to line pressure. Refer to Table 1 for Maximum

Purge Flows at 100 psig (7kgf/cm

2

).

Loading...

Loading...