20

© SPX

Form No. 1000572

Rev. 0 February 8, 2012

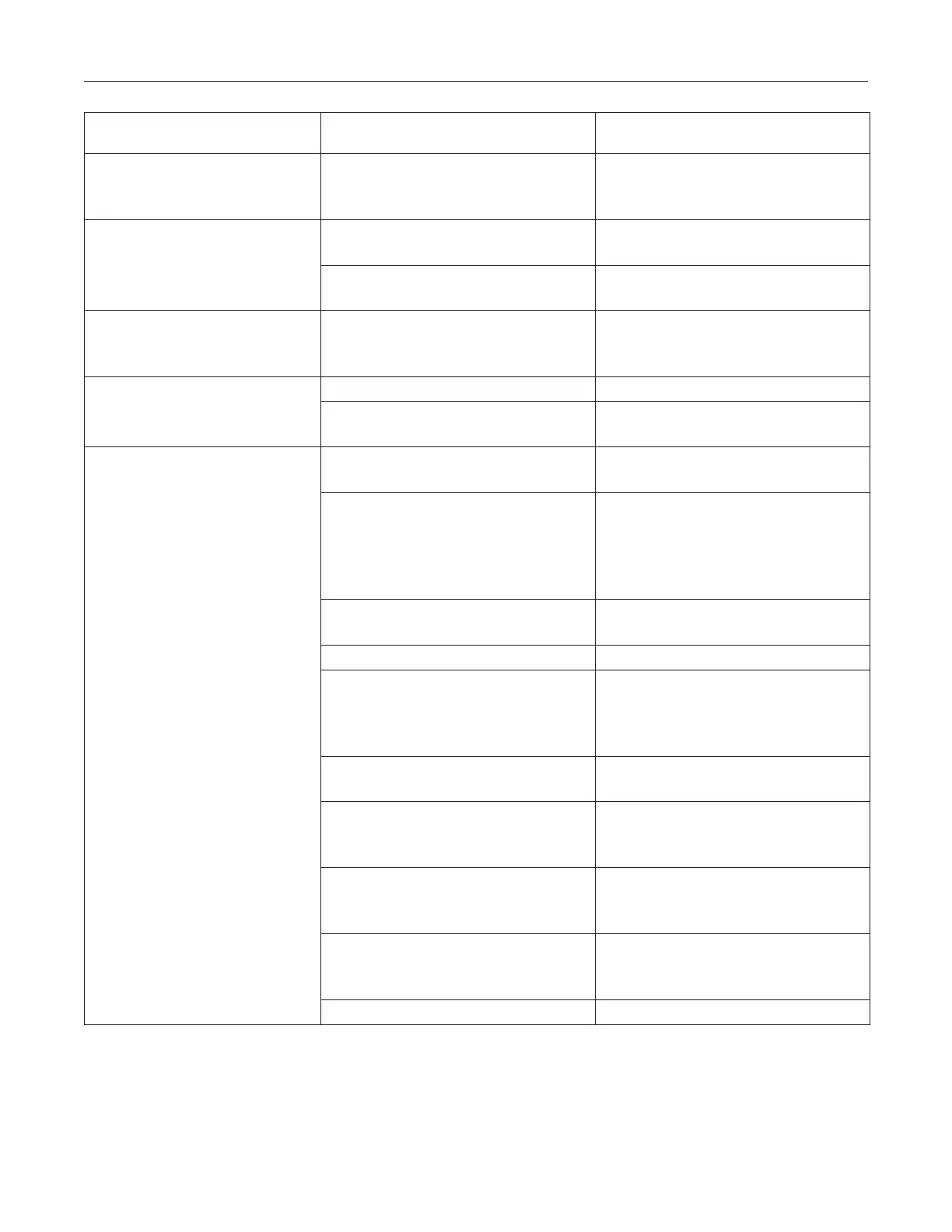

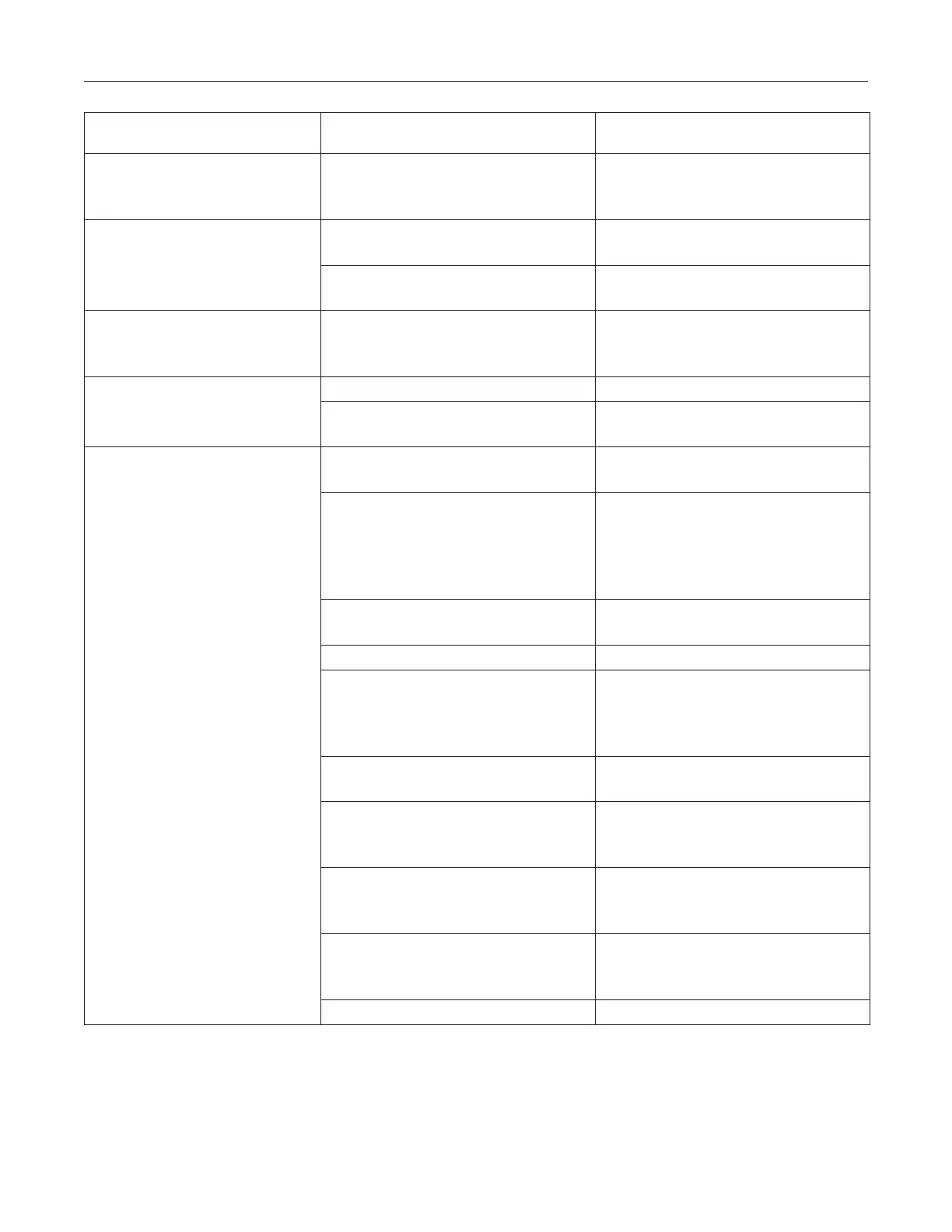

Troubleshooting Guide continued

Problem Cause Solution

Electric motor will not shut

off.

1. Defective motor controls.

1. Disconnect unit from power

supply; contact a Power Team

Service Center.

Electric motor stalls,

surges, overheats, or will

not start under load.

1. Low voltage

1. Refer to electric motor

information in Initial Setup section.

2. Electrical cord size too small.

2. Refer to electrical cord chart in

Initial Setup section.

Electrical overload

protector keeps tripping.

1. Wired incorrectly.

1. Disconnect unit from power

supply; have qualied electrician

review motor and circuit wiring.

Pump delivers excess uid

pressure.

1. Faulty pressure gauge.

1. Replace gauge.

2. Relief valve set incorrectly.

2. Contact a Power Team Service

Center.

Pump is not delivering

uid, or delivers only

enough uid to advance

connected components

partially or erratically or

operation to slow.

1. Fluid level too low.

1. Add uid, refer to lling the pump

reservoir in Initial Setup section.

2. Loose-tting coupler to

component.

2.

Verify quick-disconnect couplings

to cylinders are completely coupled.

Couplers may need to be replaced

because ball check does not stay open

due to wear.

3. Air in system.

3. Refer to Initial Setup in this

manual to bleed air from system.

4. Air leak in suction line.

4. Check and tighten suction line.

5. Debris in pump or lter plugged.

5. Clean pump lter. If problem

persists, disconnect from power

supply contact authorized Power

Team service center.

6. Fluid bypasses through the

double-acting cylinder.

6. Remove cylinder; cap hoses.

Check pump and valve for leaks.

7. Cold uid or uid too heavy.

(Hydraulic uid is of a higher

viscosity than necessary.)

7. Drain, ush, and rell reservoir

using a lighter weight uid. Refer to

General Maintenance section.

8. External relief valve or low

pressure unloading valve out of

adjustment.

8. Refer to Adjusting the Pressure

Regulating Valve.

9. Power unit/reservoir capacity

is too small for the size of the

cylinder(s) used.

9. Use smaller cylinder(s) or larger

reservoir.

10. Vacuum in reservoir.

10. Clean plugged vent in ller plug.

Loading...

Loading...