SQlab | SPORTS ERGONOMICS | 3OX, 3OX CARBON, 3OX LTD. CAMO, 3OX FABIO WIBMER, 3OX TRIAL FABIO WIBMER AND 311 FL-X CARBON | EDITION US 2021-01 | Page 12

Assembly of the add-on components

Now mount the missing components on the handlebars (e.g. speedometer, grips and Innerbarends). To keep the bolt forces low while

still avoiding twisting of the components, use the supplied assembly paste when mounting the brake and shi levers, Innerbarends (if

present) and grips.

Warning

The tightening torque of the clamping screws on the stem depends on the stem mod-

el. However, do not use a stem in which the tightening torque of the screws on the

handlebar clamp according to the manufacturer is greater than 8Nm. Exceeding the

tightening torque can lead to bre cracks or pinching, which can cause a handlebar

failure that could cause a fall.

Hinweis

Note

Explicitly allowed are innerbarends made of plastic or carbon bre, which are placed

between brake lever and the grips. For example the SQlab Innerbareds 410/402, 411

and 411 R Carbon. Not allowed are innerbarends with a clamp made of aluminium.

Aer 20-50 km and then at least four times a year, check the tightening torque of the

clamping screws and tighten them if necessary. When checking, make sure not to

exceed the maximum tightening torque.

Warning

Sharp-edged, unfavourably designed

and badly placed components, as well

as those which are to be mounted on

the handlebars with a bolt tightening

force greater than 6 Nm, can cause -

bre cracks, notches and constrictions.

• Never install components that are

clamped in the bends of the handle-

bars.

• Do not install bar ends that are

mounted outside the handlebar

grips or inside the brake levers.

• Refrain from mounting such compo-

nents

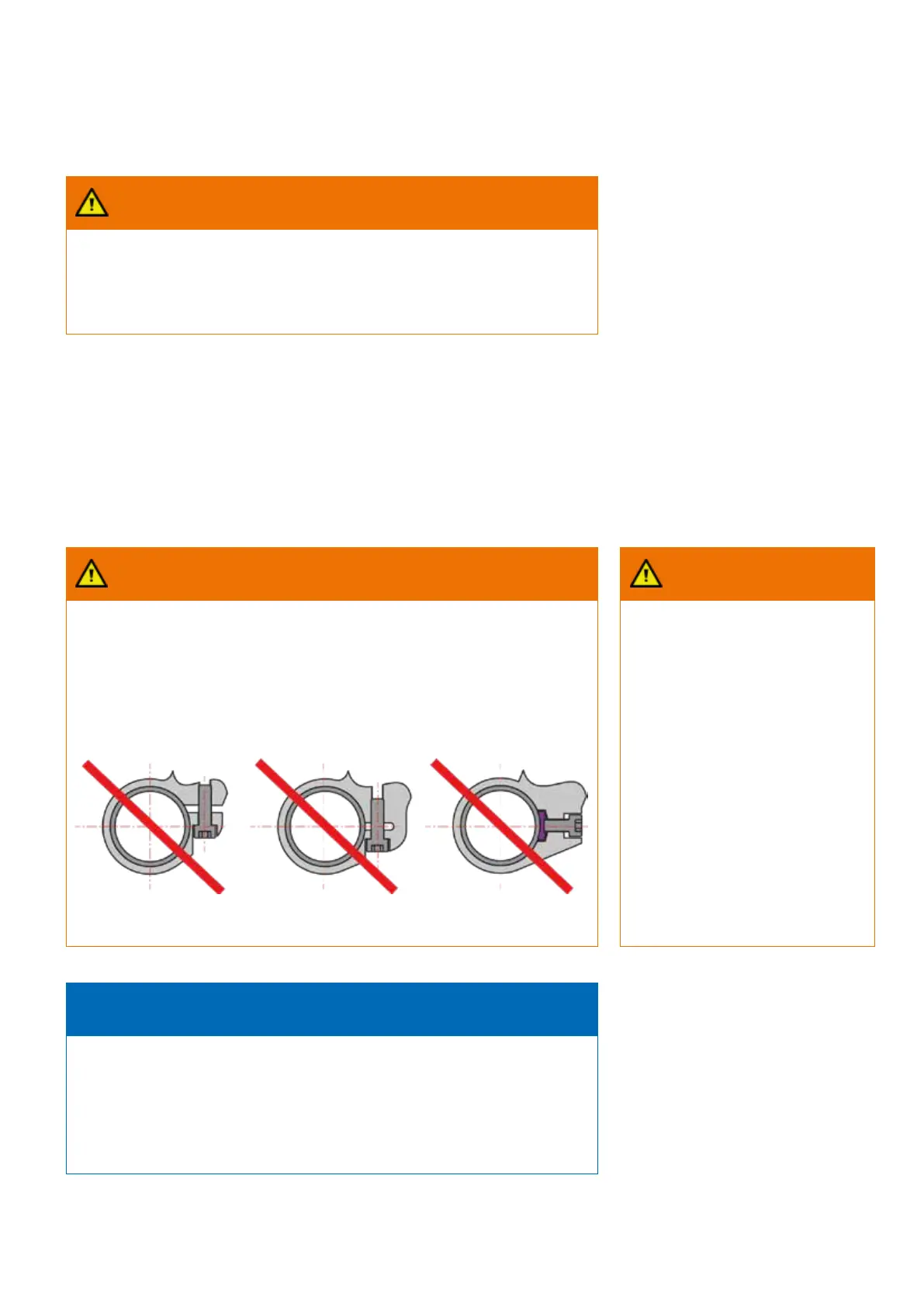

Warning

Unfavourably designed clamping mechanisms of some add-on components are not

compatible with our carbon handlebars. Despite compliance with the screw tighten-

ing forces, bre tears and de-laminations may occur. Never use components with the

following characteristics:

• Asymmetrical clamping slot

• Internal clamping slot

• Segment clamping

Fig.: Asymmetrical clamping, closed clamping rings with internal clamping slot and segment

clamping.

Loading...

Loading...