SECTION FOUR – Routine Maintenance and Professional Servicing

LL

LL

oo

oo

cc

cc

aa

aa

tt

tt

ii

ii

oo

oo

nn

nn

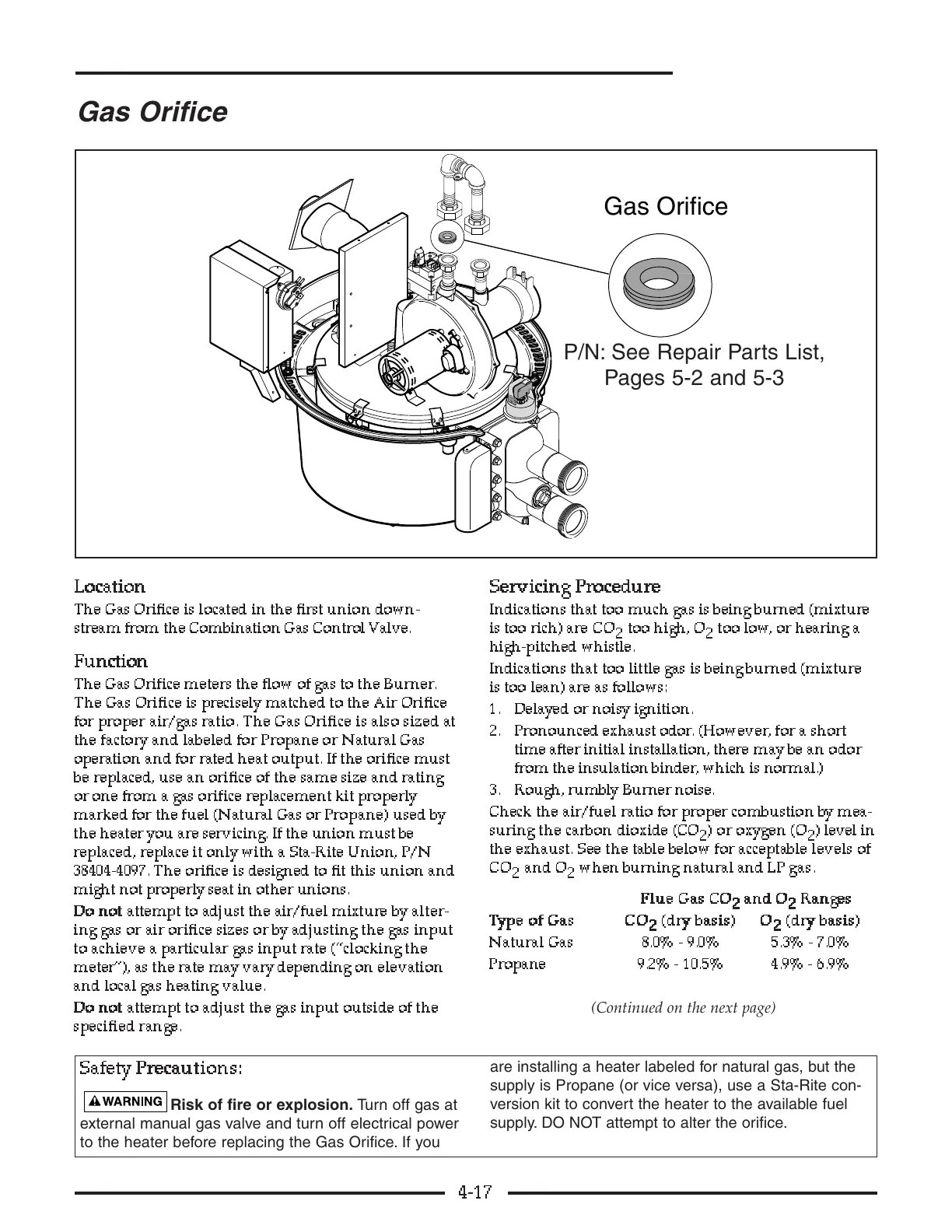

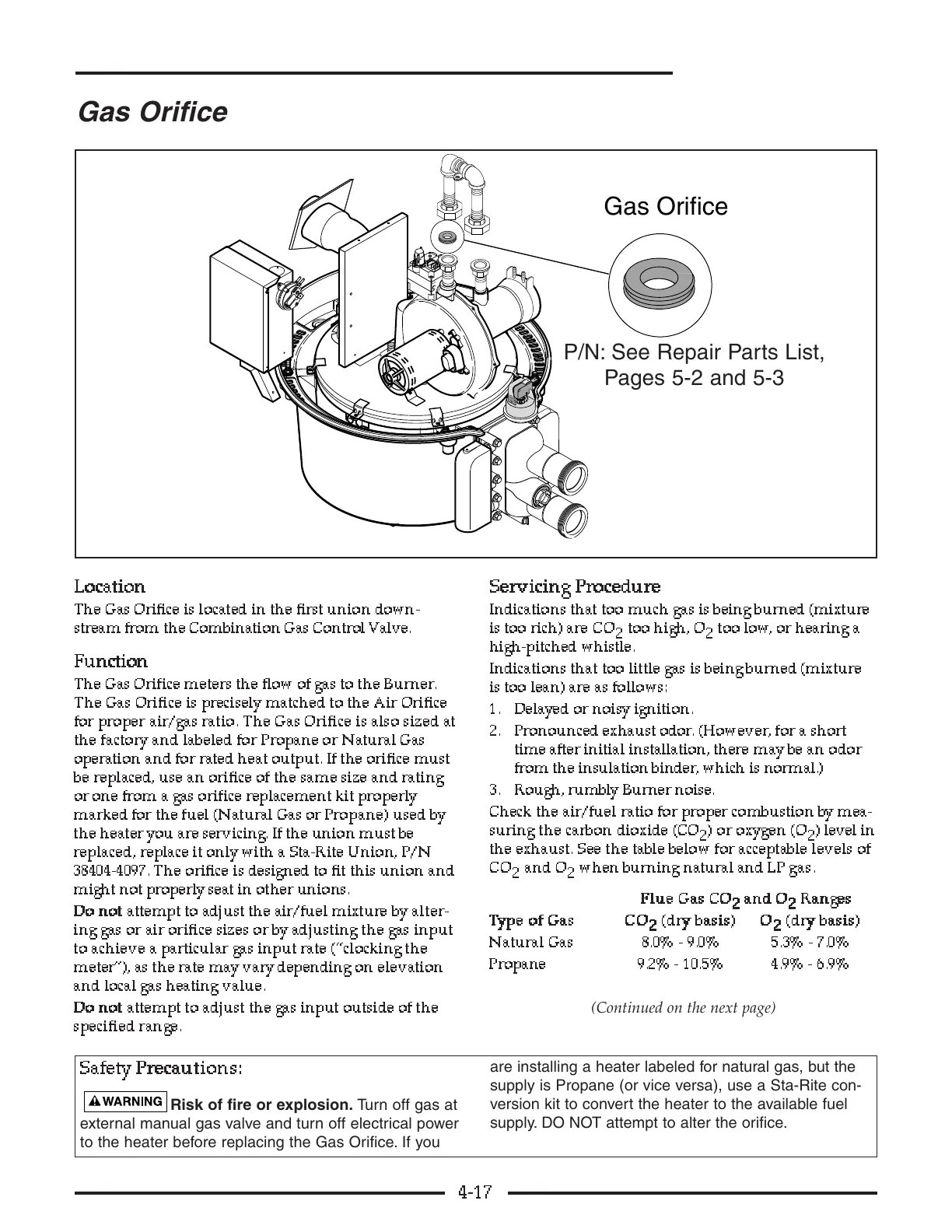

The Gas Orifice is located in the first union down-

stream from the Combination Gas Control Valve.

FF

FF

uu

uu

nn

nn

cc

cc

tt

tt

ii

ii

oo

oo

nn

nn

The Gas Orifice meters the flow of gas to the Burner.

The Gas Orifice is precisely matched to the Air Orifice

for proper air/gas ratio. The Gas Orifice is also sized at

the factory and labeled for Propane or Natural Gas

operation and for rated heat output. If the orifice must

be replaced, use an orifice of the same size and rating

or one from a gas orifice replacement kit properly

marked for the fuel (Natural Gas or Propane) used by

the heater you are servicing. If the union must be

replaced, replace it only with a Sta-Rite Union, P/N

38404-4097. The orifice is designed to fit this union and

might not properly seat in other unions.

DD

DD

oo

oo

nn

nn

oo

oo

tt

tt

attempt to adjust the air/fuel mixture by alter-

ing gas or air orifice sizes or by adjusting the gas input

to achieve a particular gas input rate (“clocking the

meter”), as the rate may vary depending on elevation

and local gas heating value.

DD

DD

oo

oo

nn

nn

oo

oo

tt

tt

attempt to adjust the gas input outside of the

specified range.

SS

SS

ee

ee

rr

rr

vv

vv

ii

ii

cc

cc

ii

ii

nn

nn

gg

gg

PP

PP

rr

rr

oo

oo

cc

cc

ee

ee

dd

dd

uu

uu

rr

rr

ee

ee

Indications that too much gas is being burned (mixture

is too rich) are CO

2

too high, O

2

too low, or hearing a

high-pitched whistle.

Indications that too little gas is being burned (mixture

is too lean) are as follows:

1. Delayed or noisy ignition.

2. Pronounced exhaust odor. (However, for a short

time after initial installation, there may be an odor

from the insulation binder, which is normal.)

3. Rough, rumbly Burner noise.

Check the air/fuel ratio for proper combustion by mea-

suring the carbon dioxide (CO

2

) or oxygen (O

2

) level in

the exhaust. See the table below for acceptable levels of

CO

2

and O

2

when burning natural and LP gas.

FF

FF

ll

ll

uu

uu

ee

ee

GG

GG

aa

aa

ss

ss

CC

CC

OO

OO

22

22

aa

aa

nn

nn

dd

dd

OO

OO

22

22

RR

RR

aa

aa

nn

nn

gg

gg

ee

ee

ss

ss

TT

TT

yy

yy

pp

pp

ee

ee

oo

oo

ff

ff

GG

GG

aa

aa

ss

ss

CC

CC

OO

OO

22

22

((

((

dd

dd

rr

rr

yy

yy

bb

bb

aa

aa

ss

ss

ii

ii

ss

ss

))

))

OO

OO

22

22

((

((

dd

dd

rr

rr

yy

yy

bb

bb

aa

aa

ss

ss

ii

ii

ss

ss

))

))

Natural Gas 8.0% - 9.0% 5.3% - 7.0%

Propane 9.2% - 10.5% 4.9% - 6.9%

(Continued on the next page)

4-17

Gas Orifice

SS

SS

aa

aa

ff

ff

ee

ee

tt

tt

yy

yy

PP

PP

rr

rr

ee

ee

cc

cc

aa

aa

uu

uu

tt

tt

ii

ii

oo

oo

nn

nn

ss

ss

::

::

Risk of fire or explosion. Turn off gas at

external manual gas valve and turn off electrical power

to the heater before replacing the Gas Orifice. If you

are installing a heater labeled for natural gas, but the

supply is Propane (or vice versa), use a Sta-Rite con-

version kit to convert the heater to the available fuel

supply. DO NOT attempt to alter the orifice.

P/N: See Repair Parts List,

Pages 5-2 and 5-3

Loading...

Loading...