15

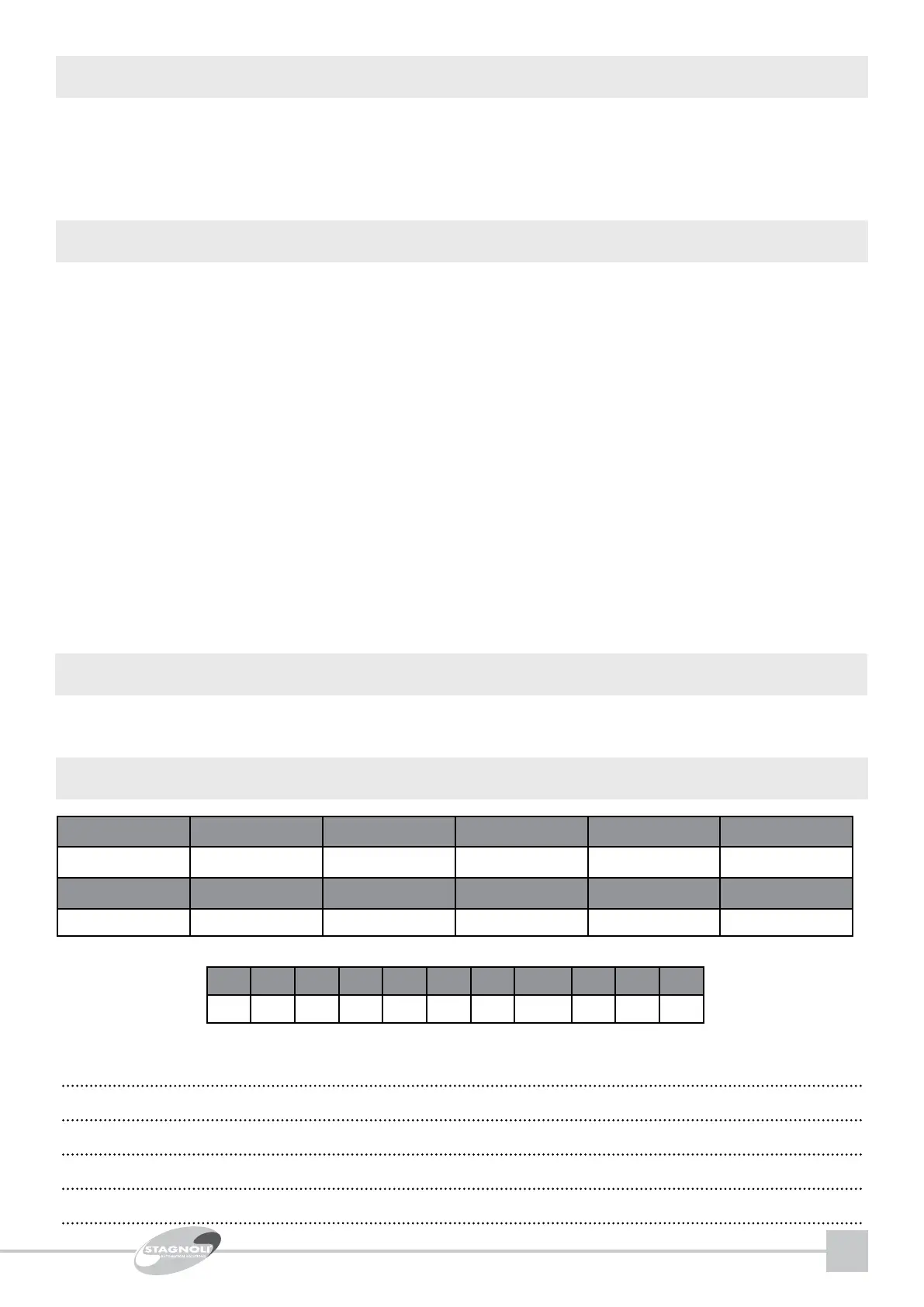

TCA TPED SFAP SFCH TRAL FAP

FCH VEL FBA SBA TINV TAUX

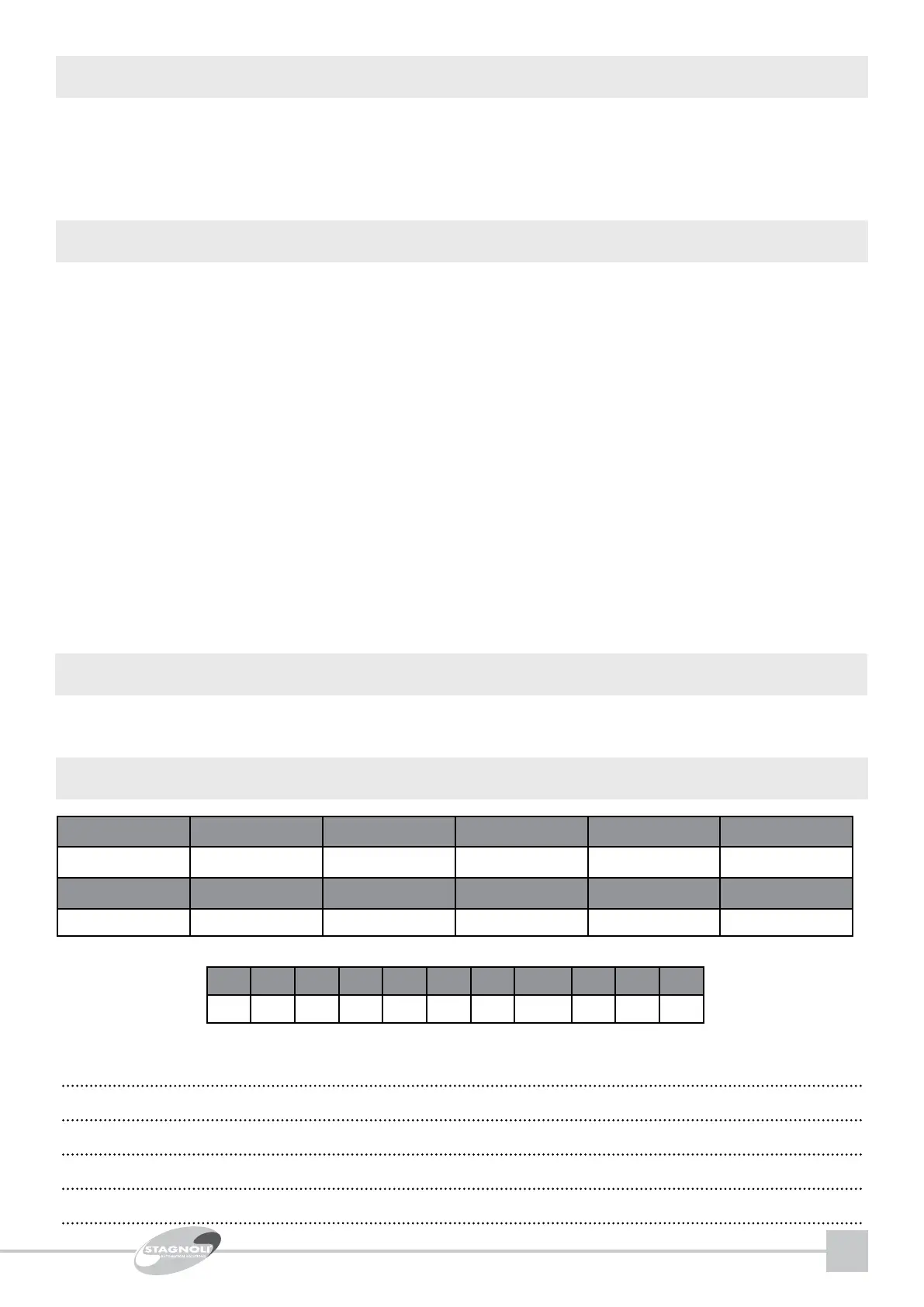

ca ba BP CR 2p PL 1m oc cf ar fc

IMPORTANT WARNINGS AND FIRST START-UP

DISPOSAL

Always perform nal testing after having completed all programming:

• Unlock motors and make sure that the leaves move freely with a force lower than 390Nm, then re-lock them.

• Check correct operation of protective devices (anti-crushing system, stop button, photocells, etc.).

• Check correct operation of signalling devices.

• Check correct operation of control devices (radio controls, selectors, etc.).

• Adjust motor working forces (FCH and FAP) in accordance with standard EN 12445 to ensure system safety.

This product is composed of various components which in turn may contain pollutants. Do not litter! Inquire about recycling or disposal of prod-

ucts according to the laws in force at the local level.

IMPORTANT WARNINGS ABOUT INSTALLATION:

• Automatic gate systems must be installed by qualied technical staff in compliance with legal requirements and meeting the requirements of

the law and in conformity with Machinery Directive 98/37/EC and standards EN13241-1, EN 12453 and EN 12445.

• Verify the solidity of existing structures (columns, hinges, leaves) in relation to forces developed by the motor.

• Verify the conditions of any cables already present in the system.

• Analyse automation risks and take the necessary safety and signalling precautions accordingly.

• Install controls (for example key selectors) to keep users out of danger zones.

• Once installation has been completed, test safety, signalling and automation unlocking devices a few times (see FINAL TESTING).

• Make sure that users have understood correct automatic, manual and emergency operation of automation.

FIRST START-UP:

• Draft a system technical le containing: Installation drawing, Wiring diagram of connected cables, analyses of risks present and adopted

solutions, analyses of residual risks still present, declaration of conformity of all products drafted by the manufacturer and a declaration of

conformity relative to installation completed by the installer.

• Afx the CE label or plate containing hazard information and identifying data (serial number, etc.) to the machine.

• Deliver instructions for use, safety warnings, CE declaration of conformity and a copy of the technical le to the end user.

Also make sure to inform the end user:

• regarding the possible presence of unprotected residual risks and foreseeable improper use

• of the importance of disconnecting power supply when performing cleaning in the automation area or when performing small maintenance

operations (i.e. repainting)

• on the need to frequency verify that there is no visible damage to automation or, if any is detected, to immediately alert the installer

• with regards to the danger of letting children play in the immediate vicinity of automation

• Prepare a system maintenance schedule (at least every 6 months for safety devices), keeping notes regarding operations performed in a

log.

FINAL TESTING

We recommend using the spaces below to write down the parameters you have customised.

NOTES:

NOTES ON PARAMETERS AND FUNCTIONS:

Loading...

Loading...