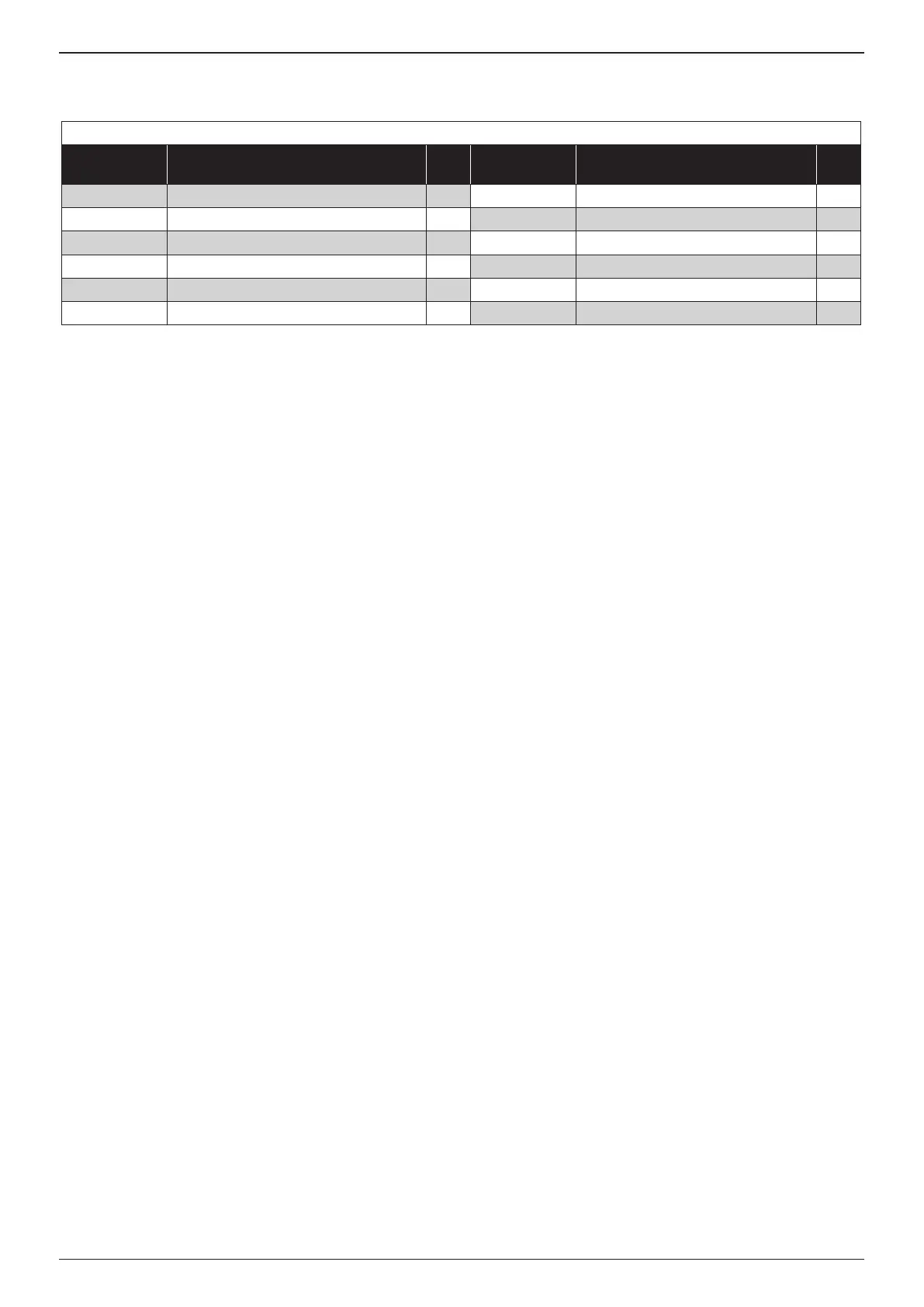

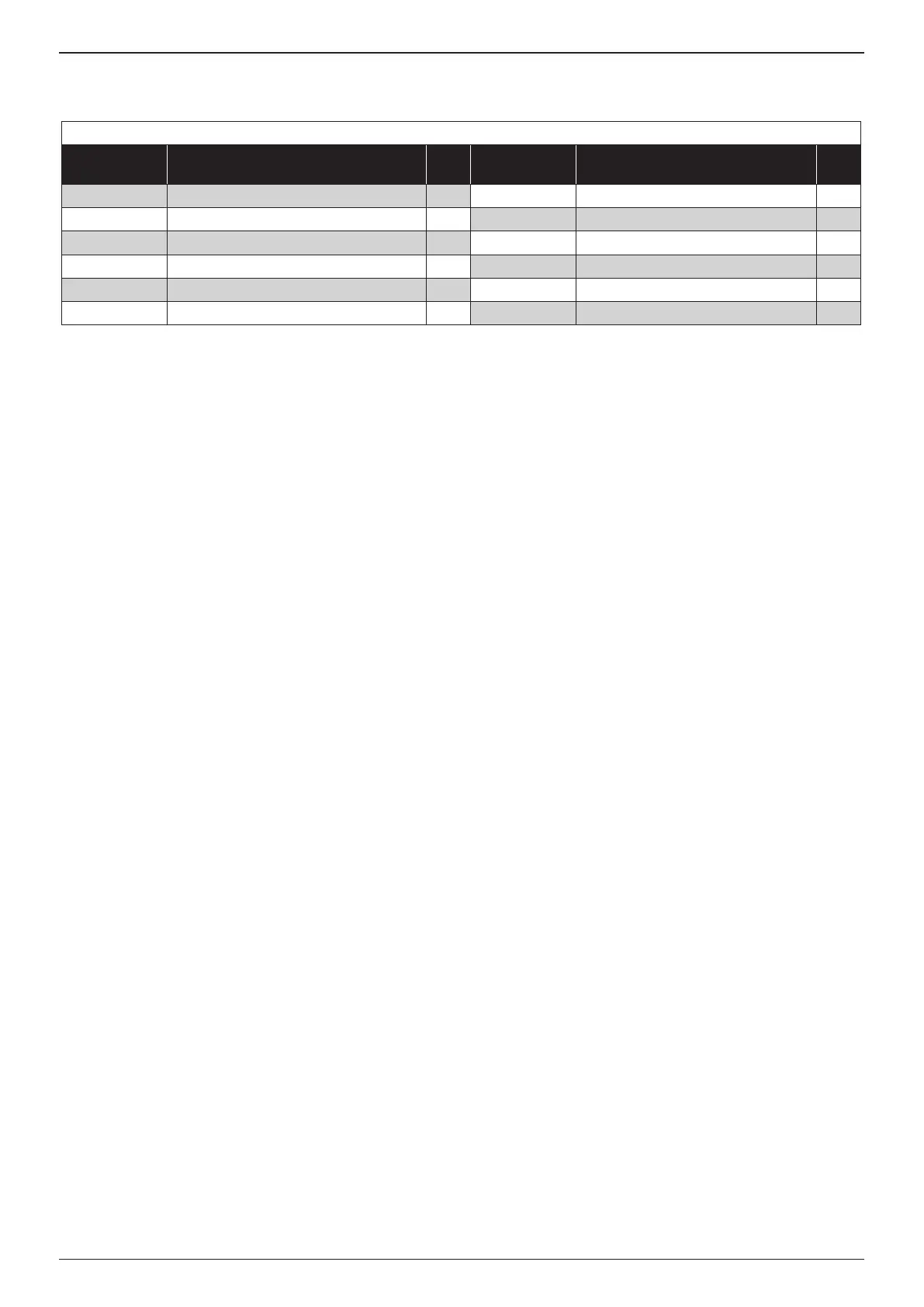

5.4 SERVICE KIT

For a complete service the following Service Kit is available:

SERVICE KIT: 70500-99990

PART

NUMBER

DESCRIPTION QT Y.

PART

NUMBER

DESCRIPTION QT Y.

07900-00013 Hexagon Wrench 1/8” A/F 1 07900-00522 Combination Spanner 2

70900-00194 Jaw Housing Key 1 07900-00006 Spatula 1

07900-00226 Hexagon Wrench 6mm A/F 1 07900-00201 Hexagon Wrench 0.50” A/F 1

07900-00433 Spanner 24 & 26mm Open Ended 1 07900-00669 Assy. Bullet (Piston) 1

07900-00434 Spanner 32 & 30mm Open Ended 1 07900-00577 Piston Assy Rod 1

07992-00020 80gm Moly-lithium Grease EP3753 1 07900-00429 Assy Spanner for Head Piston 1

5.5 HYDRAULIC OIL

The recommended oil for priming is Hyspin® VG32 available in 0.5l (part number 07992-00002) or one gallon containers

(part number 07992-00006).

5.6 DISMANTLING INSTRUCTIONS

IMPORTANT – ENSURE THE MAINS POWER AND AIR SUPPLY TO THE MACHINE AND HYDRAULIC PUMP UNIT IS

SWITCHED OFF BEFORE DISMANTLING THE TOOL.

Instructions on installing and removing the module from the machine frame will be included in the Technical Manual

supplied with the machine. The Technical Manual will include full instructions on the dismantling, maintenance and

assembly of the tool.

Before Dismantling:

• Remove the module from the machine.

• Remove the nose equipment from the module as per the instructions in the Technical Manual supplied with the

machine.

• The potentially dangerous substances that could have deposited on the machine as a result of work processes must be

removed before maintenance.

For a complete service of the tool, we advise that you proceed with dismantling the tool in the order shown on pages 8

to 10. After dismantling the tool we recommend that you replace all seals.

Dismantling Instructions:

• Remove barrel lock nut (07650-00501 x2) and barrel washer (07660-00202 x 2) from barrel.

• Remove rear plug (Item 29) and O-ring (Item 12) by unscrewing using 1" Spanner. Use 1" spanner on rear cylinder (Item

28) to counter the rotation.

• Remove seal retainer (Item 30).

• Slide out piston assembly consisting of items (8, 10, 16, 26 and 37). Use circlip pliers to remove circlip (Item 16) to

disengage piston (Item 26) from piston rod (Item 27).

• Unscrew with 1" spanner rear cylinder (Item 28) and O-ring (Item 12) from rear cylinder (Item 28). Inside this cylinder is

another O-ring (Item 8). Replace as necessary.

• Remove second seal retainer (Item 30).

• Slide out second piston assembly consisting of items (8, 10, 16, 26 and 37). Use circlip pliers to remove circlip (Item 16)

disengage piston (Item 26) from piston rod (Item 27).

• Unscrew with 1" spanner second rear cylinder (Item 28) and O-ring (Item 12) from third rear cylinder (Item 28). Inside

this cylinder is another O-ring (Item 8). Replace as necessary.

• Remove third seal retainer (Item 30).

• Unscrew front cylinder (Item 44) from tail jaw housing (Item 42). This pulls out front piston rod (Item 49) and assembly.

• Slide banjo (Item 43) o from cylinder (Item 44).

• Use circlip pliers to remove circlip (Item 16) to disengage piston (Item 26) from front piston rod (Item 49). O-rings (Items

4, 7, 8, 9 and 10) can be removed.

• Remove turret jaws (Item 19) from turret (Item 22). Unscrew turret (Item 22) from front piston rod (Item 49).

• Optional: Unscrew grub screw (Item 53) from port B.

• Unscrew adaptor (Item 24) from tail jaw housing (Item 42) using 1” spanner and 26mm spanner.

9

ORIGINAL INSTRUCTION ENGLISH

Loading...

Loading...