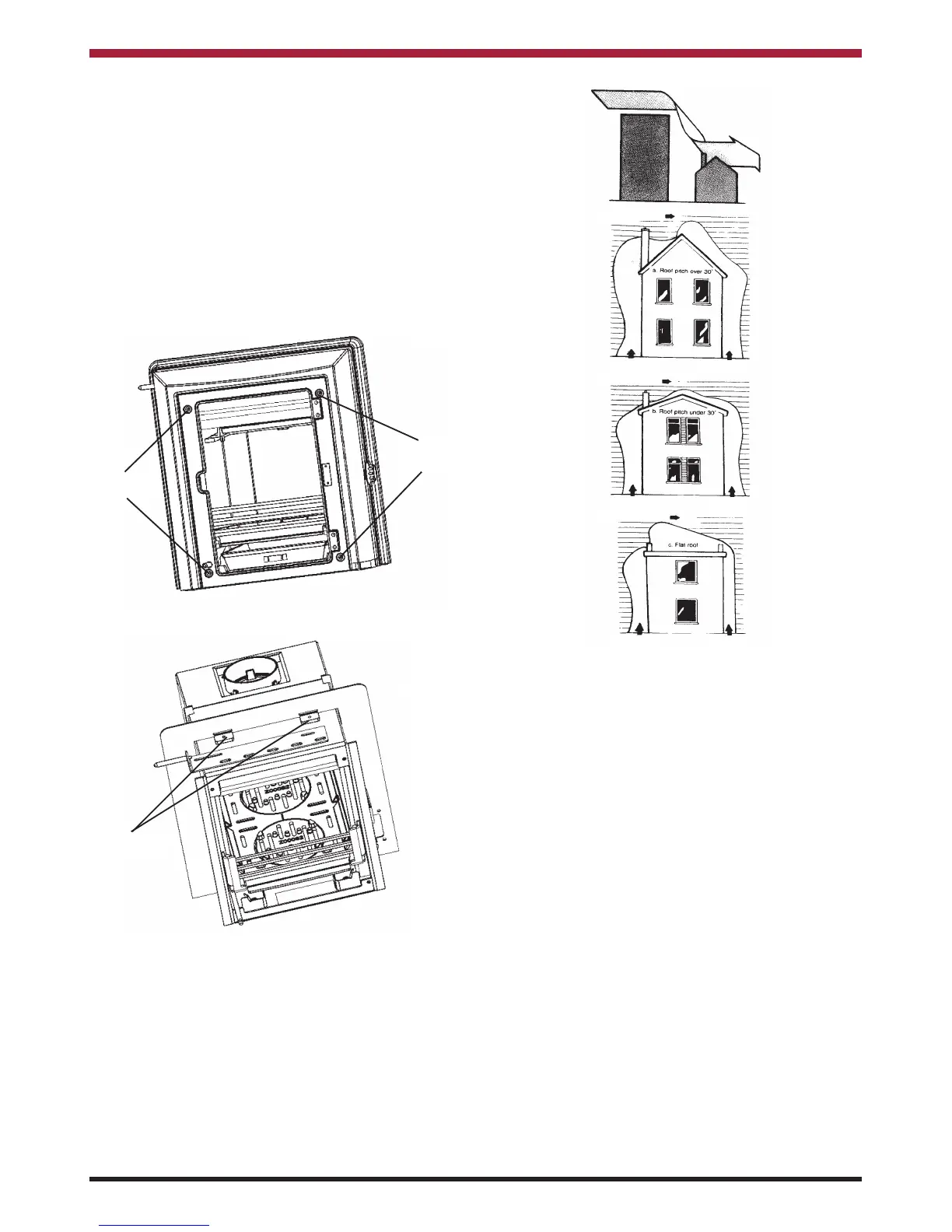

Then remove the 4 front fixing screws (see Fig.10)

which will allow the front casting and the surround-

ing shroud to be removed from the boiler by sliding

it to the left to clear the secondary air control rod and

then pulling it forward, in some circumstances it may

be necessary to unscrew the secondary air contol

rod before removing the front. The wall flange can

then be removed by unscrewing the fixings on top

and sliding it up clear of the guides. (see Fig.11)

Make the required connections and replace the front

in reverse order making sure that the front seals fully

to the boiler.

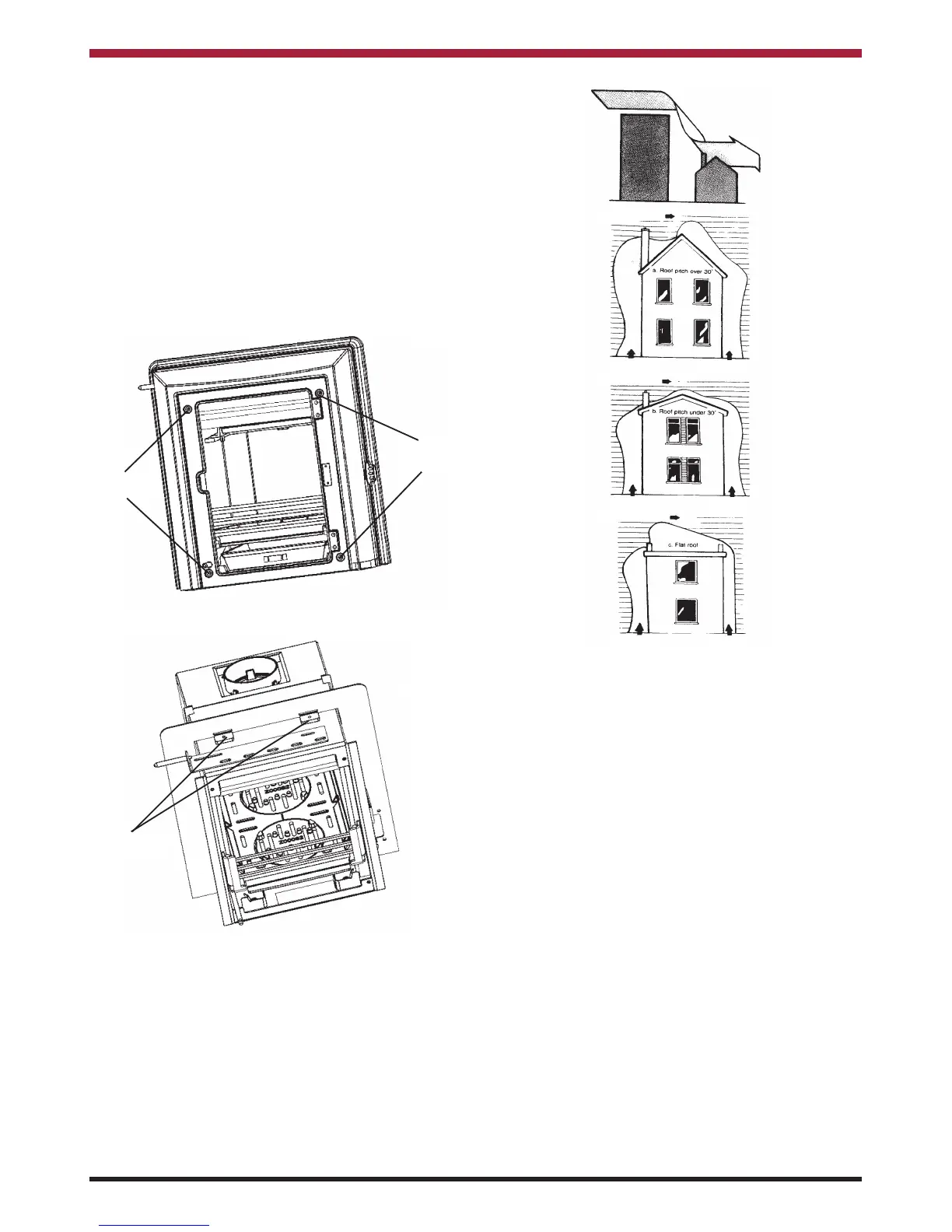

DOWN DRAUGHTS

However well designed constructed and positioned,

the satisfactory performance of the flue can be

adversely affected by down draught caused by near-

by hills, adjacent tall buildings or trees. These can

deflect wind to blow directly down the flue or create

a zone of low pressure over the terminal. A suitable

anti-down draught terminal or cowl will usually effec-

tively combat direct down blow but no cowl is likely

to prevent down draught due to a low pressure zone.

(See Fig.12)

Direction of wind

Direction of wind

Direction of wind

Pressure zone

Pressure zone

Suction zone

Suction zone

Pressure zone Suction zone

Fig 12

Fig 10

Front Fixing

Screws

Front Fixing

Screws

Top Fixings

Fig 11

7

VENTILATION AND COMBUSTION AIR

REQUIREMENTS

It is imperative that there is sufficient air supply to

support correct combustion. The minimum effective

air requirement for this appliance is 54cm

2

. When

calculating combustion air requirements for this

appliance use the following equation: 550mm

2

per

each kW of rated output above 5 kW should be pro-

vided, where a flue draught stabiliser is used the

total free area shall be increased by 300mm

2

for

each kW of rated output. If there is another appli-

ance using air fitted in the same or adjacent room, it

will be necessary to provide an additional air supply.

Especially Airtight Properties:-

If the stove is being fitted in a property where the

design air permeability is less than 5m

3

/ (h.m

2

) (nor-

mally newer properties built from 2006), then a per-

manent ventilation must be fitted to provide 550mm

2

of ventilation for each kW of rated output. If a

draught stabiliser is also fitted then the requirement

is 850mm

2

per kW of rated output.

Loading...

Loading...