17

G

B

compatible manner at the appropriate collection

point.

6.3 Safety valve (ref. 10)

The safety valve has been set for the highest

permitted pressure of the pressure vessel. It is

prohibited to adjust the safety valve or remove its

seal.Actuatethesafetyvalvefromtimetotimeto

ensurethatitworkswhenrequired.Pulltheringwith

sufficient force until you can hear the compressed

airbeingreleased.Thenreleasetheringagain.

6.4 Storage

Warning!

Pull the mains plug out of the socket and

ventilate the appliance and all connected

pneumatic tools.

Switch off the compressor and make sure that it

is secured in such a way that it cannot be started

up again by any unauthorized person.

Warning!

Store the compressor only in a dry location which

is not accessible to unauthorized persons.

Always store upright, never tilted!

7. DISPOSAL AND RECYCLING

The unit and its accessories are made of various

typesofmaterial,suchasmetalandplastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local

council.

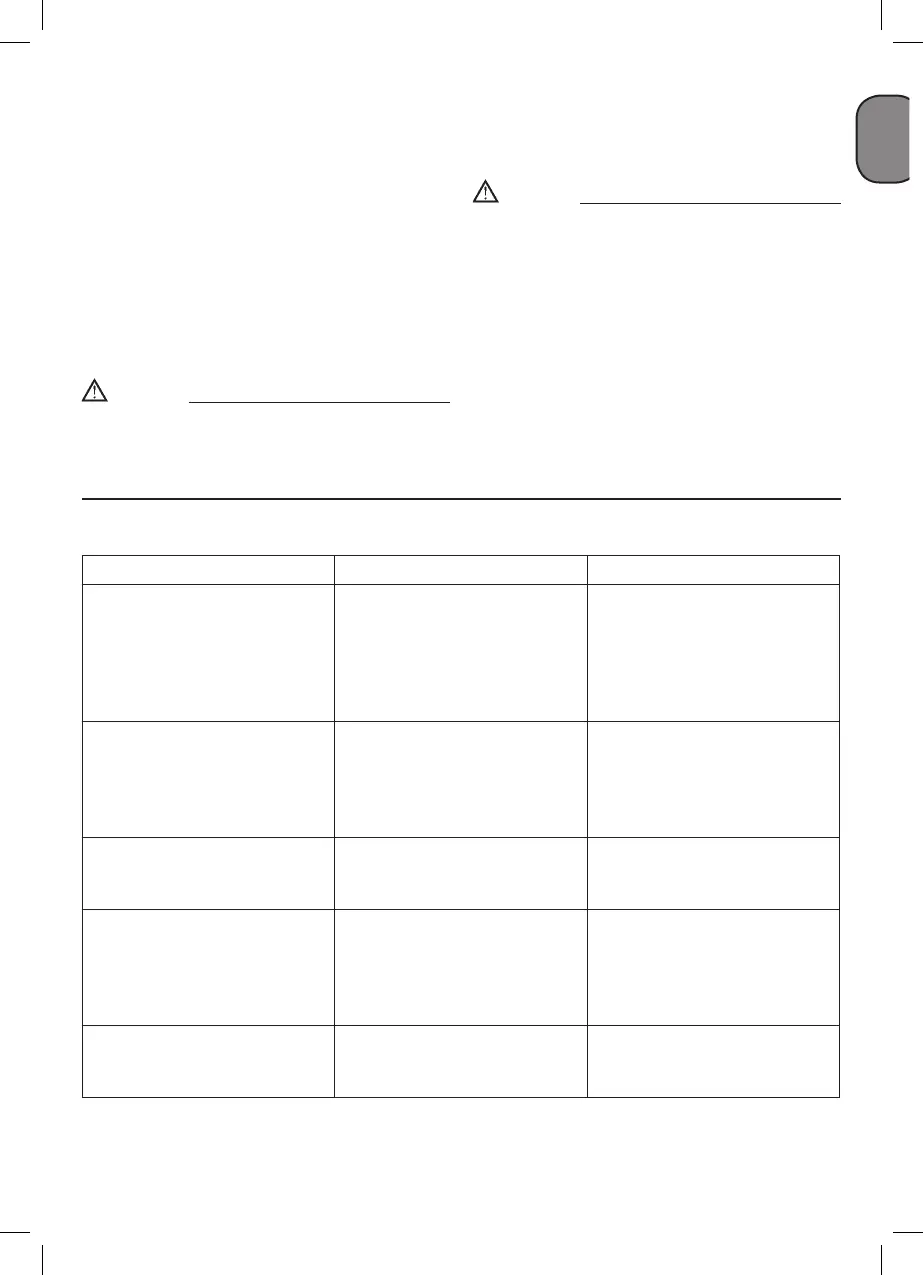

8. POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

FAULT CAUSE REMEDY

Leakage of air from the valve

of the pressure switch with

thecompressoroff.

Check valve that, due to wear

or dirt on the seal, does not

performitsfunctioncorrectly.

Unscrew the hexagonal head

of the check valve, clean the

valve seat and the special

rubberdisk(replaceifworn).

Reassemble and tighten

carefully.

Reductionofperformance.

Frequentstart-up.Low

pressurevalues.

Excessive performance

request, check for any leaks

from the couplings and/or

pipes.Intakeltermaybe

clogged.

Replace the seals of the

tting,cleanorreplacethe

lter.

Thecompressorstopsand

restarts automatically after a

fewminutes.

Trippingofthethermalcutout

due to overheating of the

motor.

Clean the air ducts in the

conveyor.Ventilatethework

area.

After a few attempts to

restart,thecompressor.

Trippingofthethermalcutout

due to overheating of the

motor(removaloftheplug

with the compressor running,

lowpowervoltage).

Activatetheon/offswitch.

Ventilatetheworkarea.

Waitafewminutes.The

compressor will restart

independently.

Thecompressordoesnot

stop and the safety valve is

tripped.

Irregular functioning of the

compressor or breakage of

thepressureswitch.

Remove the plug and contact

theServiceCenter.

Any other type of operation must be carried out by authorized Service Centers, requesting

original parts. Tampering with the machine may impair its safety and in any case make the

warranty null and void.

Loading...

Loading...