13

ENGLISH

(Original instructions)

Note!Should nails continue to jam frequently in contact trip,

have tool serviced by an authorized STANLEY FATMAX

service center.

Cold Weather Operation

When operating tools at temperatures below freezing:

u Keep tool as warm as possible prior to use.

u Actuate the tool 5 or 6 times into scrap lumber before

using.

Hot Weather Operation

Tool should operate normally. However, keep tool out of direct

sunlight as excessive heat can deteriorate bumpers and other

rubber parts resulting in increased maintenance.

No-mar tip (Fig. O)

The tool comes equipped with a spare no-mar tip (19) located

on the side of the nail magazine.

To replace the no-mar pad, simply pull off the old no-mar pad

and ret the new no-mar pad onto the contact trip (8).

Replacement parts

Warning!To reduce the risk of personal injury, disconnect

battery pack from tool and engage trigger lock-off before

performing maintenance, or clearing a jammed nail.

The tool comes equipped with a spare no mar tip located on

the side of the nail magazine.

Use only identical replacement parts. For a parts list or to

order parts, visit our service website at www.stanley.eu/3co.

uk. You can also order parts from your nearest

STANLEY FATMAX Factory Service Center or STANLEY

FATMAX Authorized Warranty.

Accessories

Warning! Since accessories, other than those offered by

STANLEY FATMAX, have not been tested with this product,

use of such accessories with this tool could be hazardous.

To reduce the risk of injury, only STANLEY FATMAX

recommended accessories should be used with this product.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center.

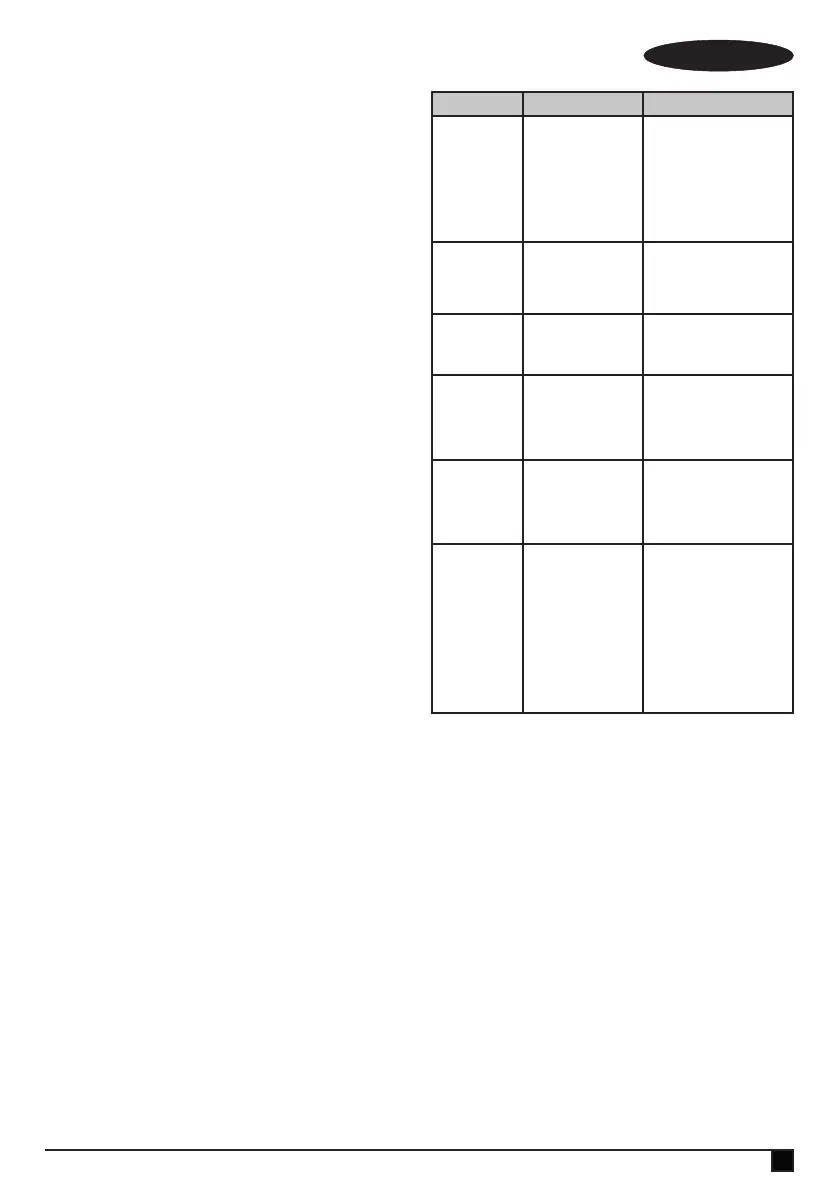

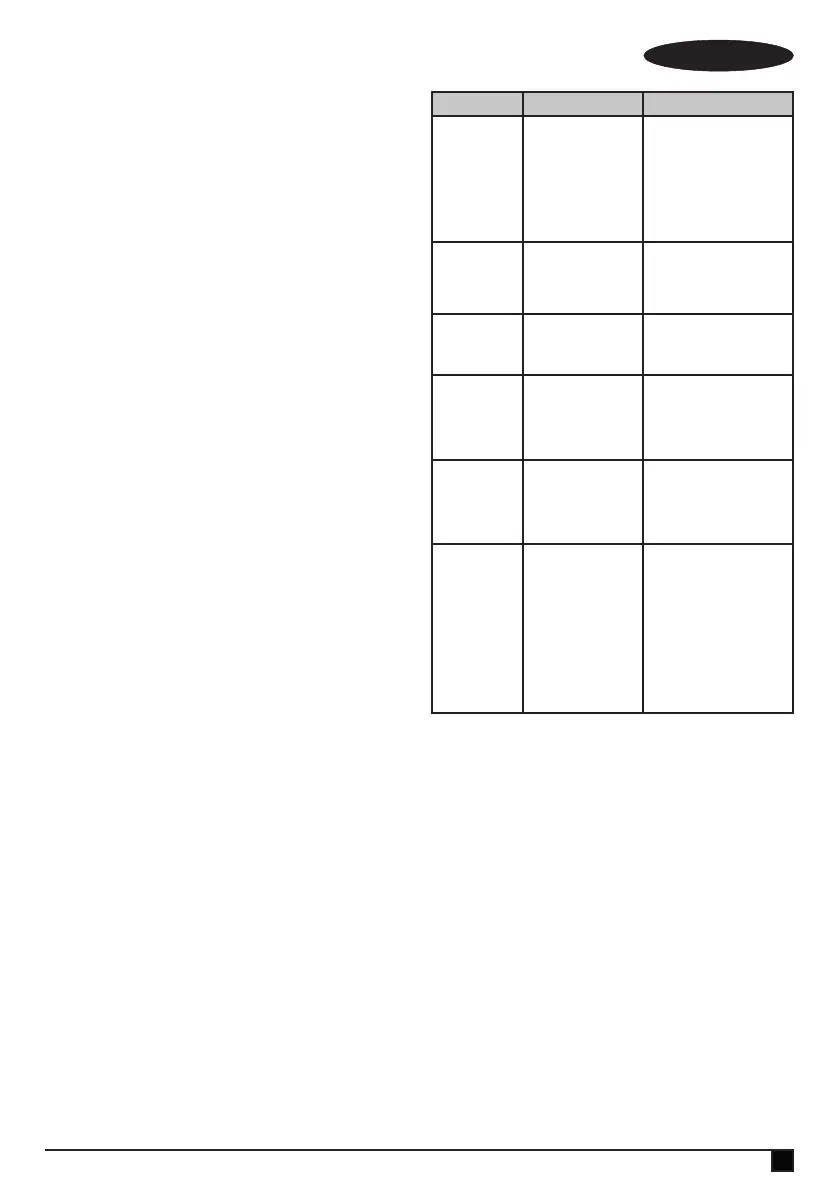

Troubleshooting

If your appliance seems not to operate properly, follow the

following instructions.

If this does not solve the problem, please contact your local

STANLEY FATMAX repair agent.

Warning! Before proceeding, unplug the appliance.

Problem Possible Cause Possible Solution

Unit will not start. Battery pack not

installed properly.

Battery pack not

charged.

Trigger lock-off is

engaged.

Check battery pack

installation.

Check battery pack charging

requirements.

Disengage trigger lock-off.

Tool doesn’t

actuate.

(Headlights on,

motor does not

run)

Motor stops running

after 2 seconds.

Normal operation; release

trigger or contact trip and

re-depress.

Tool doesn’t

actuate.

(Headlights

ash)

Low battery charge or

damaged battery.

Charge or replace battery.

Tool doesn’t

actuate.

(Headlights ash

continuously)

Jammed fastener / tool

stalled.

Jammed mechanism

Remove the battery, rotate the

stall release lever. Clear the

jammed fastener, and reinsert

battery pack.

See authorized service center.

Tool doesn’t

actuate.

((Headlights on,

motor runs,

driver blade

stuck down)

See authorized service center.

Tool operates,

but does

not drive the

fastener fully.

Low battery charge or

damaged battery.

Depth adjustment set

too shallow.

Tool not rmly applied

to workpiece.

Material and fastener

length too rigorous an

application.

Charge or replace battery.

Rotate depth adjustment

wheel to

a deeper setting.

Read instruction manual.

Choose appropriate material

or fastener length.

Maintenance

Your STANLEY FATMAX corded/cordless appliance/tool has

been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory opera-

tion depends upon proper tool/appliance care and regular

cleaning.

Warning! Switch off and unplug the appliance before carrying

out any cleaning.

u Dirt and grease may be removed from the exterior of the

appliance using a cloth.

Warning! NEVER use solvents or other harsh chemicals

for cleaning the non-metallic parts of the appliance. These

chemicals may weaken the materials used in these parts. Use

a cloth dampened only with water and mild soap. Never let

any liquid get inside the unit; never immerse any part of the

unit into a liquid.

Warning! NEVER spray or in any other way apply lubricants

or cleaning solvents inside the tool. This can seriously affect

the life and performance of the tool.

Loading...

Loading...