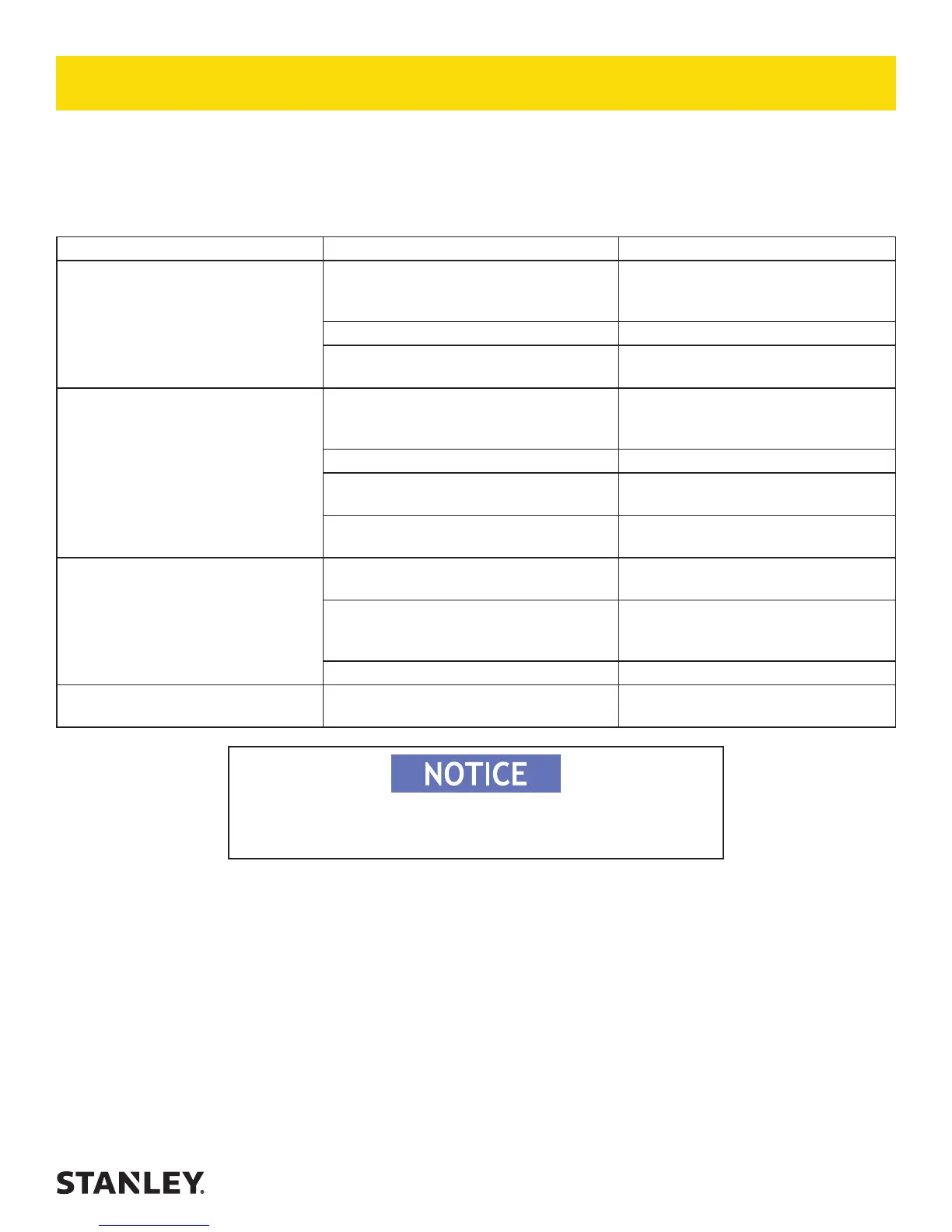

SPL31 User Manual ◄ 11

Problem Cause Solution

Spike puller does not cycle.

Hydraulic power source not functioning

correctly.

Check power source for proper ow

and pressure (5-10 GPM/19-34 LPM,

2500 psi/172 bar.

Coupler or hoses blocked. Remove obstruction.

Pressure and return line hoses reversed

at ports.

Be sure hoses are connected to their

proper ports.

Spike puller does not pull eectively.

Hydraulic power source not functioning

correctly.

Check power source for proper ow

and pressure (5-10 GPM/19-34 LPM,

2500 psi/172 bar.

Couplers or hose blocked. Remove restriction.

Fluid too hot (above 140 °F/60 °C).

Provide cooler to maintain proper uid

temperature.

The jaw is not sliding freely in the chute.

Remove, clean and replace as

required.

Spike puller operates slow.

Low oil ow from power unit.

Check power source for proper ow

and oil level.

High back pressure.

Check hydraulic system for excessive

back pressure and correct as

required.

Couplers or hoses blocked. Remove obstruction.

Jaw re-tracked with tool in neutral

position

Pressure and return lines reversed at

ports.

Be sure hoses are connected to their

proper ports.

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the spike puller, always check that the hydraulic power source is supplying

the correct hydraulic ow and pressure to the spike driver as listed in the table. Use a owmeter known to be

accurate. Check the ow with the hydraulic oil temperature at least 80 °F/27 °C.

• Always store an idle tool in a clean dry space, safe

from damage or pilferage.

• Do not exceed the rated limits or use the tool for

applications beyond its design capacity.

• Always keep critical tool markings, such as labels

and warning stickers, legible.

• Always replace hoses, couplings and other parts

with replacement parts recommended by Stanley.

• Supply hoses must have a minimum working

pressure rating of 2500 psi/175 bar.

• Permit only experienced personnel to perform tool

repair.

• Be sure to wipe all couplers clean before con necting.

Use only lint-free cloths.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling the tool.

Failure to do so may result in damage to the quick

couplers and cause overheating of the hydraulic

system.

• Check fastener tightness often and before each use

daily.

In addition to the Safety Precautions found in this manual,

observe the following for equipment protection and care.

TROUBLESHOOTING

Loading...

Loading...