PRE-RINSING

Pre-scraping of dishes is required by Food Hygiene Regulations. The best method is to pre-rinse with

warm water with a Fisher Pre-rinse Unit - or alternatively by scraping or dunking in water. Cutlery

should be pre-soaked in warm water, preferably containing cutlery pre-soak compound - refer your

chemical supplier.

RACKING PROCEDURES

Do not overload racks or cutlery containers, minimise the overlap of crockery. Wash cutlery unsorted,

handles down. Cycle times are short and water consumption per cycle low – so there is no advantage

in overloading racks.

CYCLE TIMES

The GLV has 60 and 150 second cycles.

CHEMICAL

Correct type and quantity of detergent is essential for good results. Use good quality chemicals and

regularly check containers. Discuss the use of drying agent and cutlery pre soak solution with your

chemical supplier. Chemical concentrations can be adjusted by removing the front panel to gain access

to the pumps. Detergent concentration can be increased by turning the adjusting screw clockwise.

Rinse Fluid is set to a low injection rate and will take many cycles to prime. The operator can increase

this by turning the adjusting screw anti-clockwise.

DRYING

Single tank commercial dishwashers do not have a drying cycle. However, the machines do rinse at

high temperatures which promotes fast drying particularly when drying agents are used.

At the end of the cycle promptly remove the rack from the machine - leave the rack on the bench for 2

to 3 minutes before emptying.

Operating Procedures

REGULAR CLEANING – at least once a week

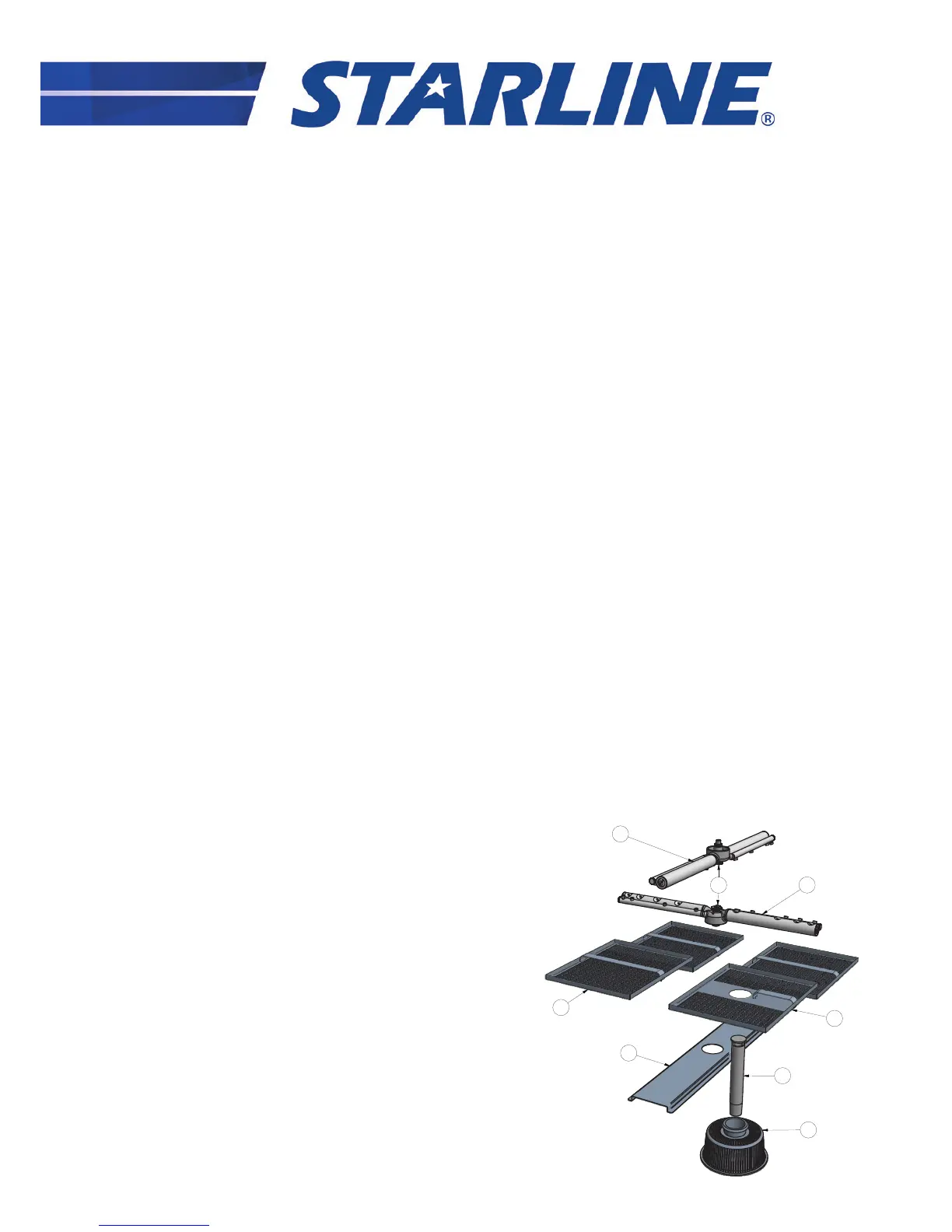

Remove wash and rinse arms (1) by undoing the central

thumbscrews (2).Inspect all jets – use toothpick or

paperclip and remove arm end-caps if necessary to

flush and clear.

Remove upstand (3), scrap trays (4, 5, 6) and filter (7).

Clean and then replace all items.

Manufactured in New Zealand by Washtech Ltd.

414 Rosebank Road, Avondale, Auckland 1026

Tel (09) 829 0930 | Fax (09) 828 9351

Web www.starline.co.nz

1

1

4

6

3

7

2

5

Loading...

Loading...