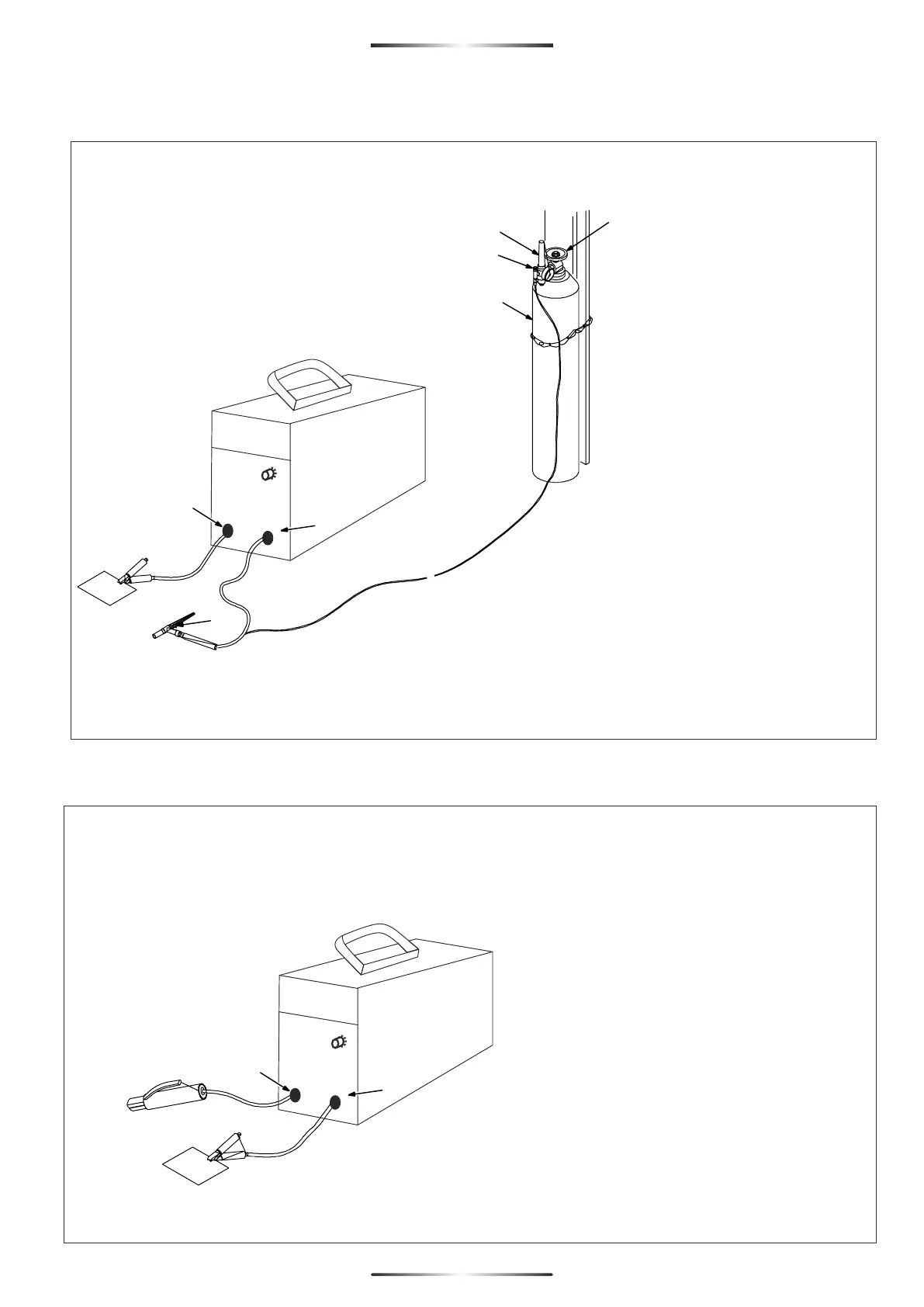

47.- TIG / LIFT ARC (Direct Current Electrode Negative) Connections

3

4

5

6

7

+

-

2

1

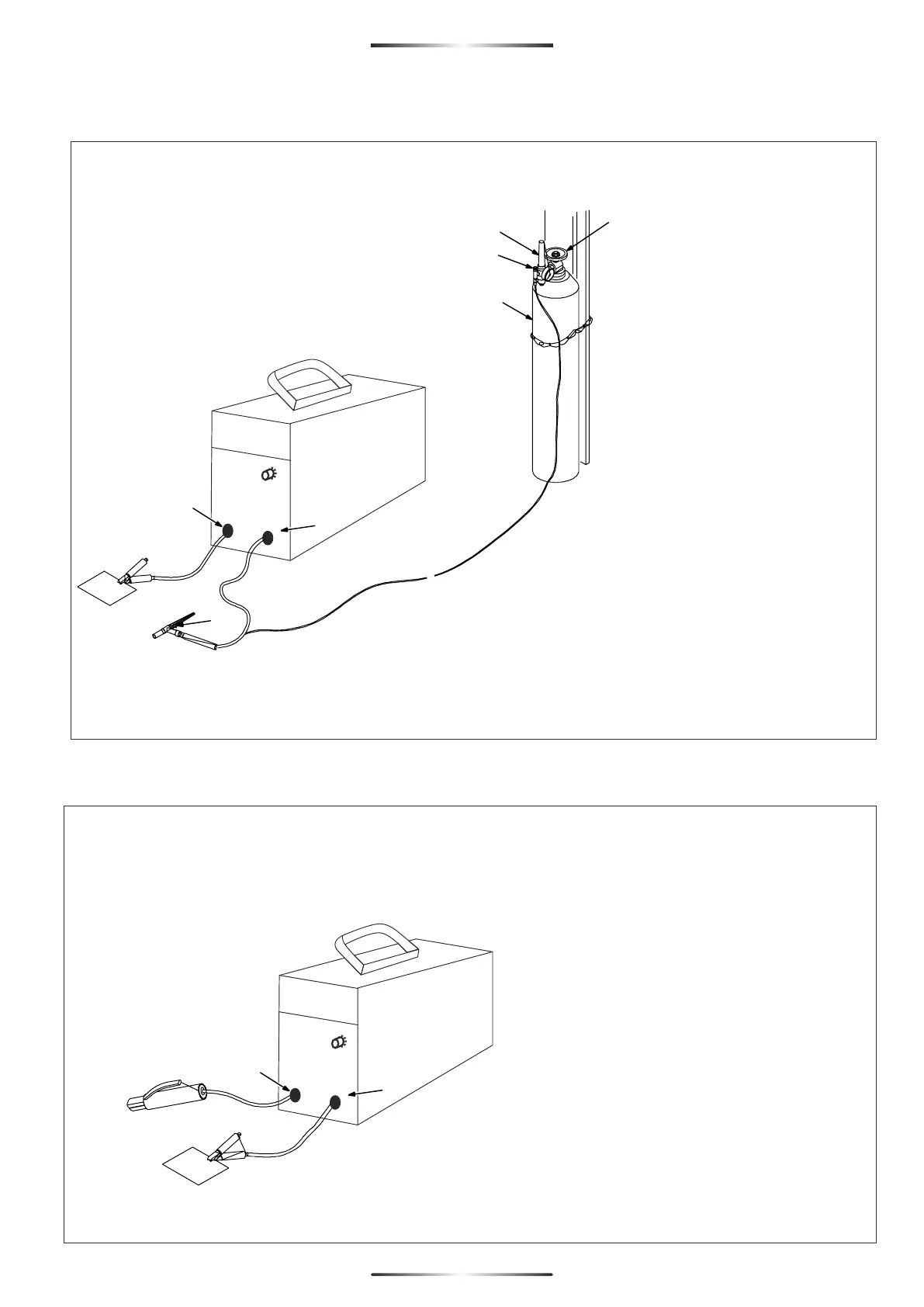

48.- Stick DCEP (Direct Current Electrode Positive) Connections

+

-

1

2

ENGLISH

24

24

1 Positive (+) Weld Output Terminal

Connect work lead to positive

weldoutput terminal.

2 Negative (−) Weld

Output Terminal Connect TIG torch to

negative weld output terminal.

3 Gas Cylinder

4 Cylinder Valve

Open valve slightly so gas flowblows dirt

from valve. Close valve.

5 Regulator/Flowmeter

6 Flow AdjustTypical flow rate is (15

cubic feet perhour) 7.1 liters per minute.

C o n n e c t t o r c h g a s h o s e t o

regulator/flowmeter.

7 Gas Valve

Valve controls gas preflow andpostflow.

Open valve on torch justbefore welding.

1 Negative (−) Weld Output Terminal

Connect work lead to negative weld

output terminal.

2 Positive (+) Weld Output Terminal

Connect electrode holder topositive weld

output terminal.

Loading...

Loading...