5 — Cycle and Control Value Programming

103

10432589_G AMSCO® 7000 Series

Operator Manual

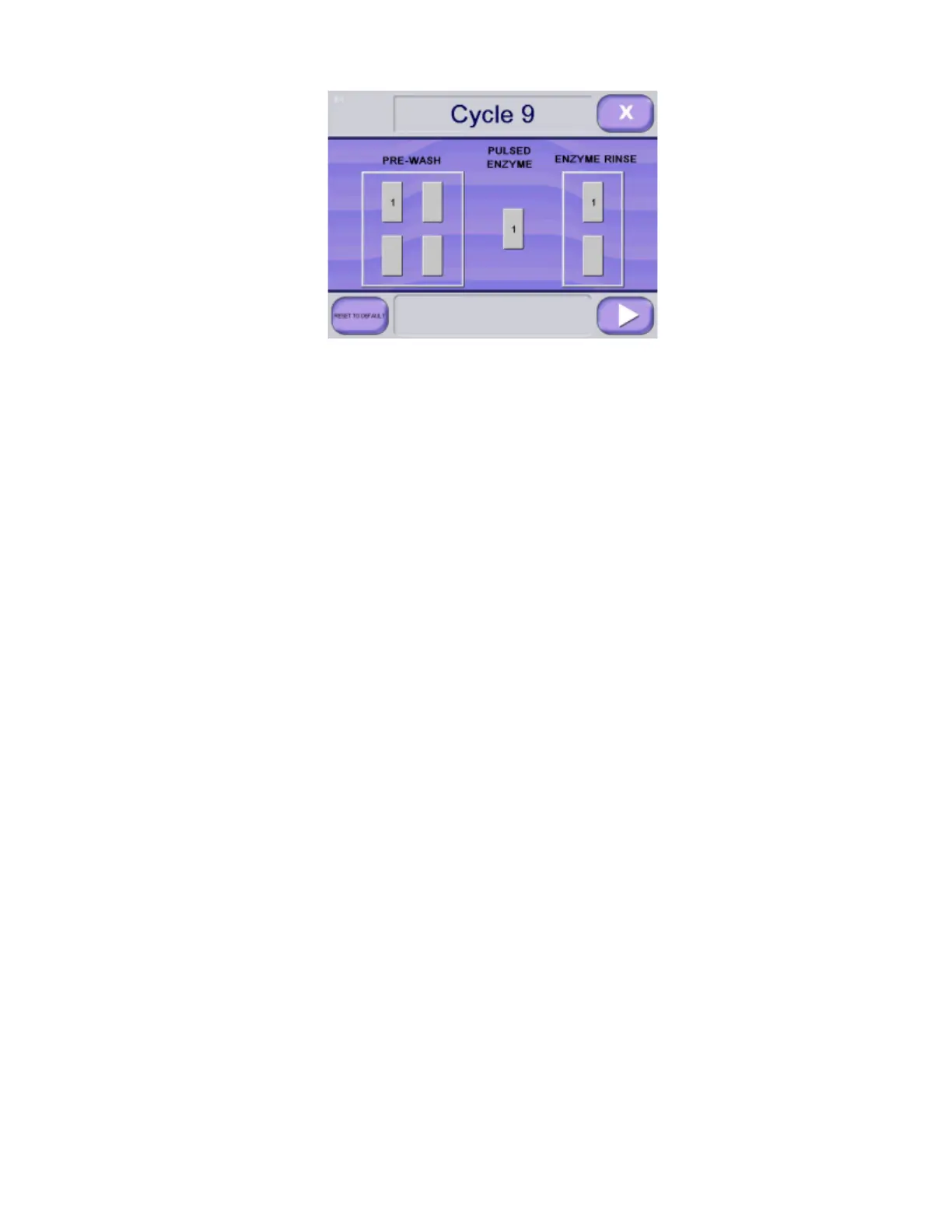

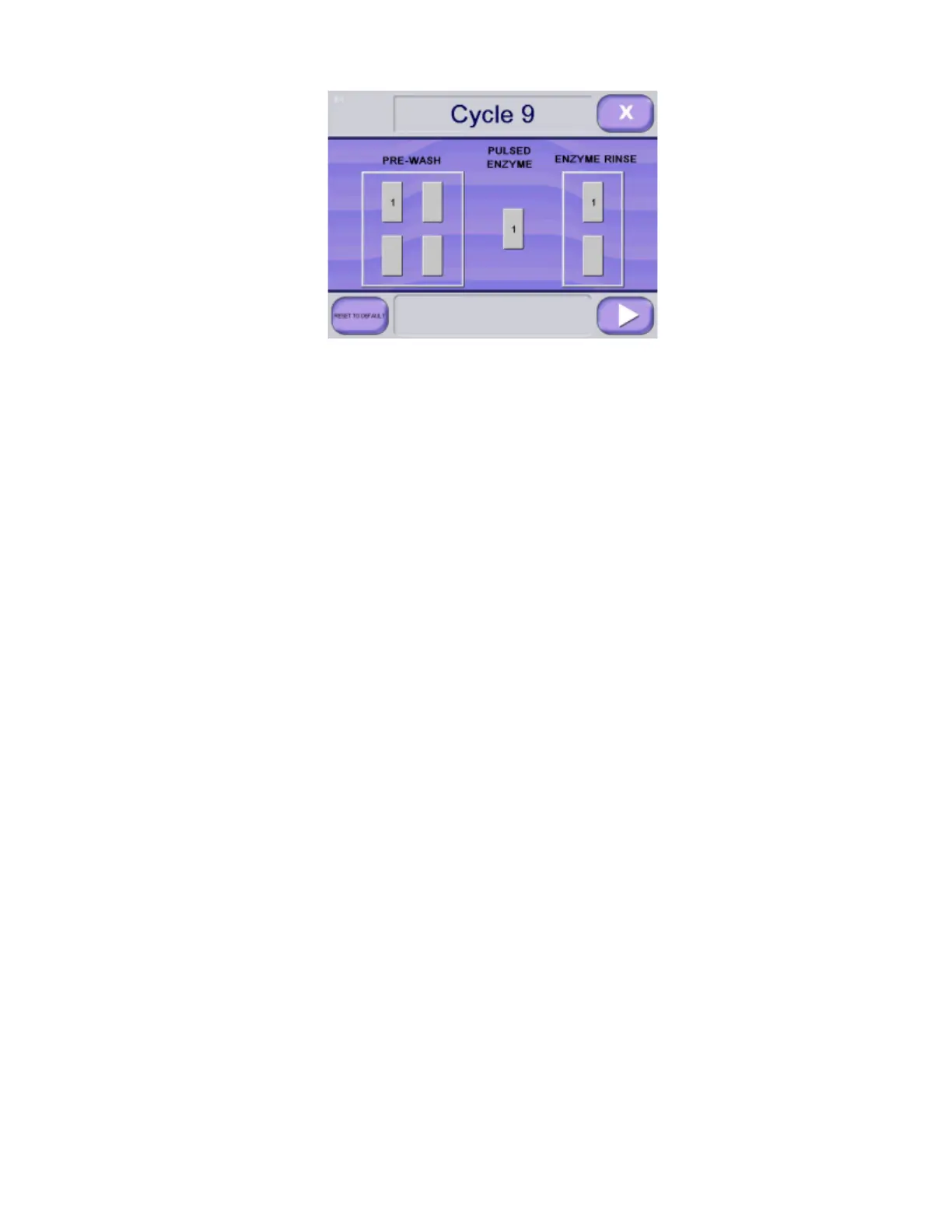

7. Follow instructions on touch screen to modify all appropriate cycle phase parameters (see Table 5-1 to Table 5-

20 for more information).

Press Right arrow to scroll across touch screen to view all following phase parameters that can be modified.

NOTE: If phase time parameter is modified to 0:00, phase will not be processed regardless of the state of any

other phase parameter. Phase button will not have any number in it indicating that phase is empty.

8. One common phase modification is for Drying. Drying phase time is adapted to typical loads processed.

Furthermore, Acu-Dry feature can be enabled or disabled. Acu-Dry DOs and DON’Ts are as follows:

• DOs

Ensure TO:

– use Acu-Dry feature on typical loads of stainless-steel instruments;

– determine typical loads and adjusted drying times by testing drying times;

– enable or disable Acu-Dry feature if Customers loads warrant it;

– avoid mixed loads.

• DON’Ts

Ensure NOT TO:

– mix plastic items with stainless-steel instruments loads;

– mix containers/utensils with stainless-steel instruments loads;

– overload trays. Instruments should not block spray arms. Instruments should be exposed to cleaning and

drying processes. Refer to Accessory Tech Data for weight capacity of each rack.

9. Once all modifications are completed, press Close on touch screen to return to Supervisor mode screen.

5.4 Transfer Cycle Reports Menu

To transfer pdf reports on USB key, proceed as follows:

1. Access Supervisor mode as explained in Section 5.2, Supervisor Mode Menus. Display shows Supervisor mode

screen:

Loading...

Loading...