10

RU

KZ

EN

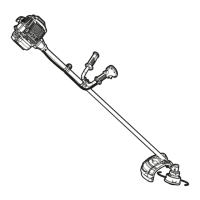

2.9 PETROL BRUSH-CUTTER AND GRASS-TRIMMER SAFETY WARNINGS

• The use of this machine may be hazardous. If the rotating line or blade comes in contact

with your body, it will cut you. When it comes in contact with solid foreign objects such as

rocks or bits of metal, it may ing them directly or by ricochet in the direction of bystanders

or the operator.

• Kick-back (blade-thrust) is the sudden and uncontrolled motion towards the operator's

right or rear that can occur when the 12 o'clock and 3 o'clock area of a rotating blade

comes in contact with a solid rigid object like a tree, rock, bush or wall. The rapid counter

clockwise rotation of the blade may be stopped or slowed, and the cutting attachment

may be thrown to the right or to the rear. This kick-back (blade-thrust) may cause loss

of control of the power tool and may result in serious or fatal injury to the operator or

bystanders. To reduce the risk of injury, extreme caution should be used when cutting with

the shaded area of any rigid blade.

• Never use a harness with a defective quick release. Use the quick release mechanism if the

engine catches re or in any other emergency situation that requires you to free yourself

from the machine or harness.

• Keep blades sharp. Tighten all nuts, bolts and screws, except the carburettor adjustment

screws, before each use.

• Wear gloves when handling or performing maintenance on blades.

• The carburettor comes from the factory with a standard setting. The carburettor has

been adjusted for optimum performance and fuel eciency in all operating states. The

carburettor shall be only adjusted by authorized person.

• Fouled air lters will impair engine performance, increase fuel consumption, excessively

wear the parts and make the machine more dicult to start. Clean the lter every 25

hours, or more regularly if conditions are exceptionally dusty. Remove the air lter cover

and take out the lter. Wash it clean in warm, soapy water. Ensure that the lter is dry

before retting it. A damaged air lter must always be replaced.

• When the engine runs short of fuel supply, check the vent valve and the fuel lter for

blockage.

• The bevel gear is lled with the right quantity of grease at the factory. However, before

using the machine you should check that the bevel gear is lled three quarters full with

grease. The grease in the bevel gear does not normally need to be changed except if repairs

are carried out.

• The spark plug condition is inuenced by:

- Incorrect carburettor adjustment.

- An incorrect fuel mixture (too much or incorrect type of oil).

- A dirty air lter.

Loading...

Loading...